Gain flattening filter for preserving the spectral bandwidth in cryogenic ultrashort-pulse laser amplifiers

a laser amplifier and gain flattening technology, applied in the field of gain flattening filters for laser amplifiers, can solve the problems of spectral narrowing, general undesirable, and gain narrowing, and achieve the effect of improving pulse shape and system gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

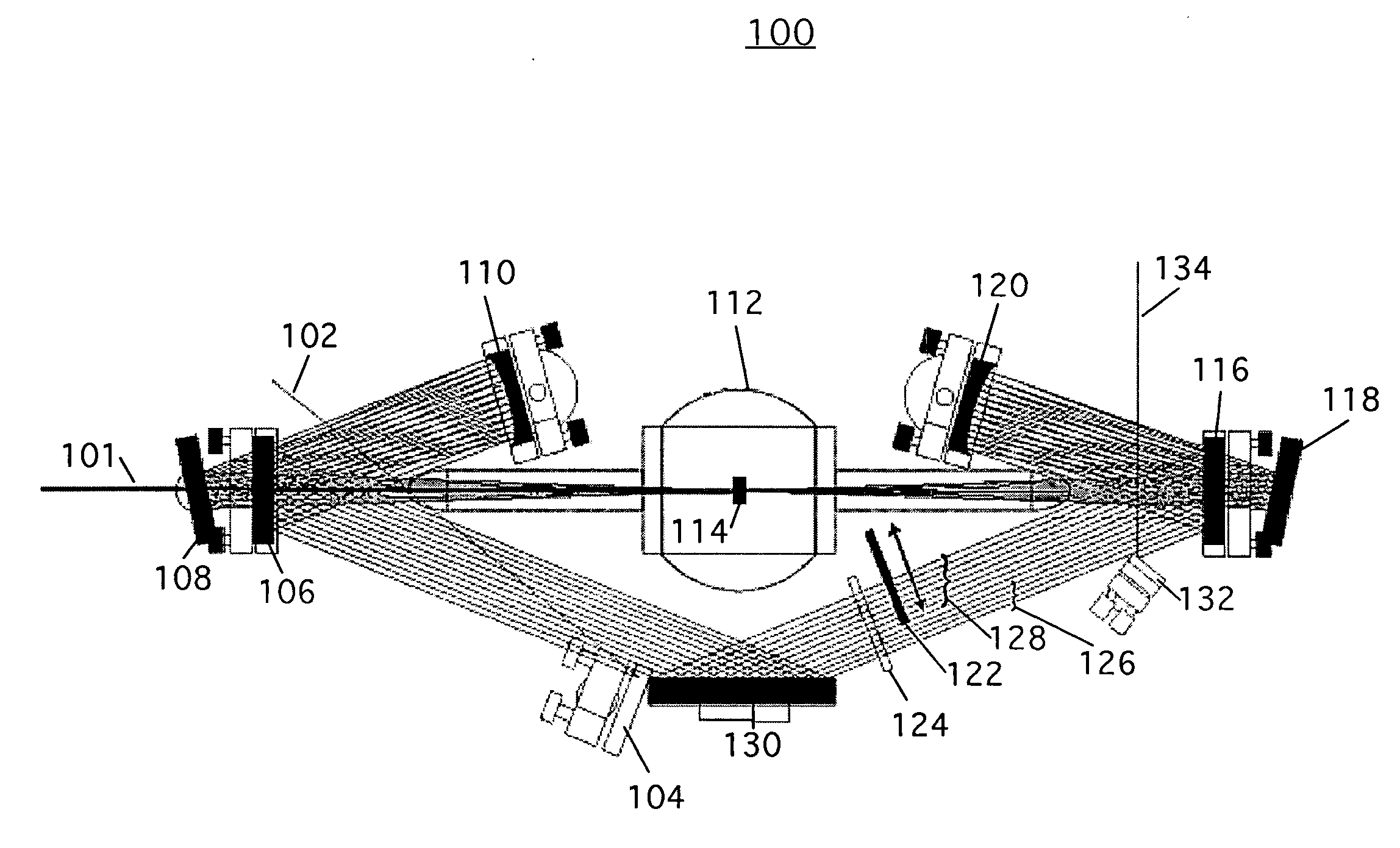

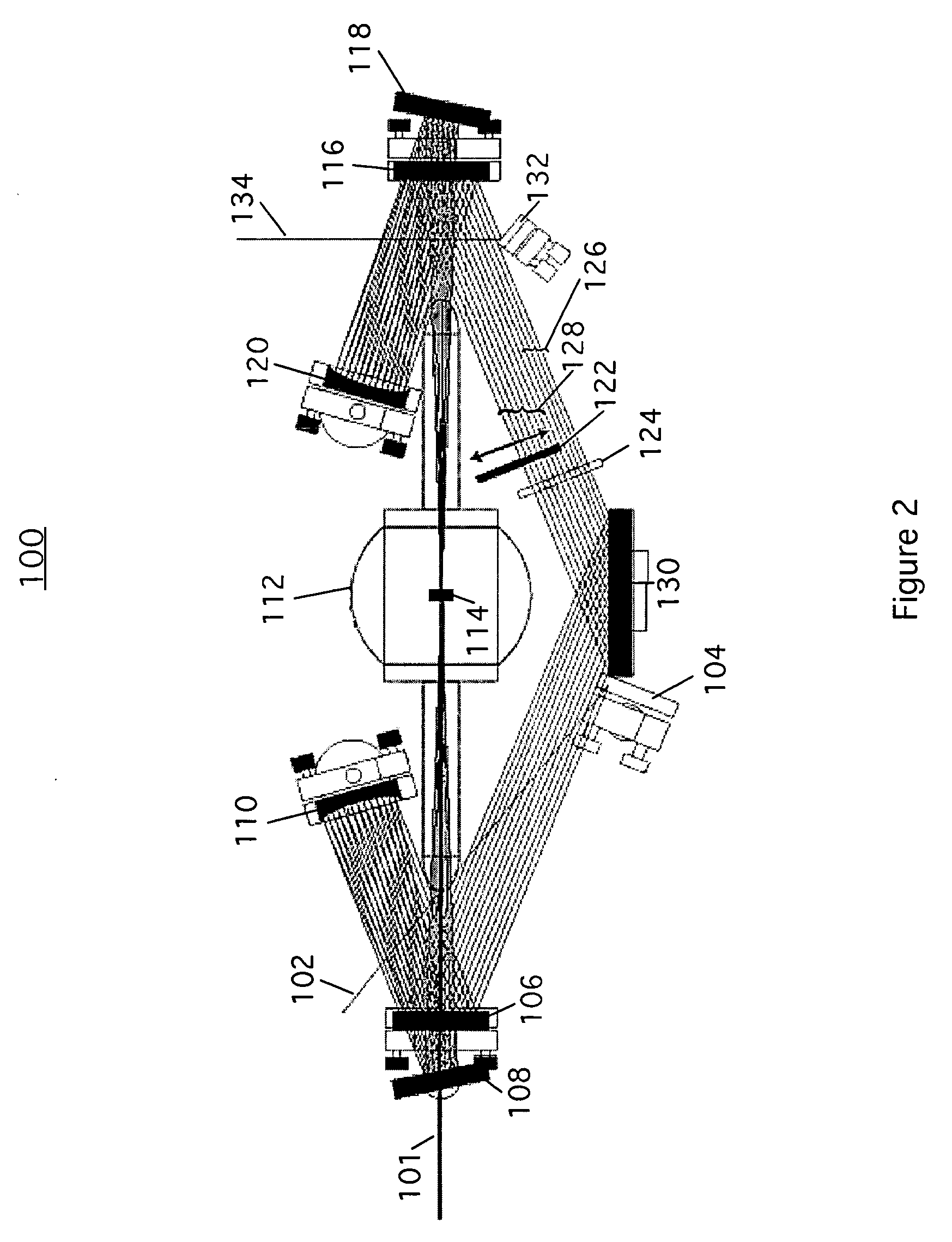

[0030]FIG. 2 is a block diagram of a preferred embodiment of a cryogenically cooled ultrafast ti:sapphire laser amplifier 100 using a gain flattening filter 122. The embodiment of FIG. 2 is a “multipass” amplifier configuration, wherein the beam shifts slightly in path with each pass, which allows the inclusion of an optional feature wherein filter 122 intersects the beam path for a variable number of passes—i.e. it intersects the first several passes 128, but the last several passes 126 bypass the filter. The final pass intersects output mirror 132 and is diverted out of the amplifier as output pulse 134.

[0031] Ultrafast laser amplifier system 100 takes an ultrashort light pulse 102, “stretches” it in time, then puts the beam through an amplification process that typically requires 8-20 passes through a laser crystal 114 to increase the output pulse 134 energy from ˜10−9 Joules to ˜10−3 J or higher. Pump beam 101 enters the system at the right in FIG. 2.

[0032] Input beam 102 refl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com