Cathode plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

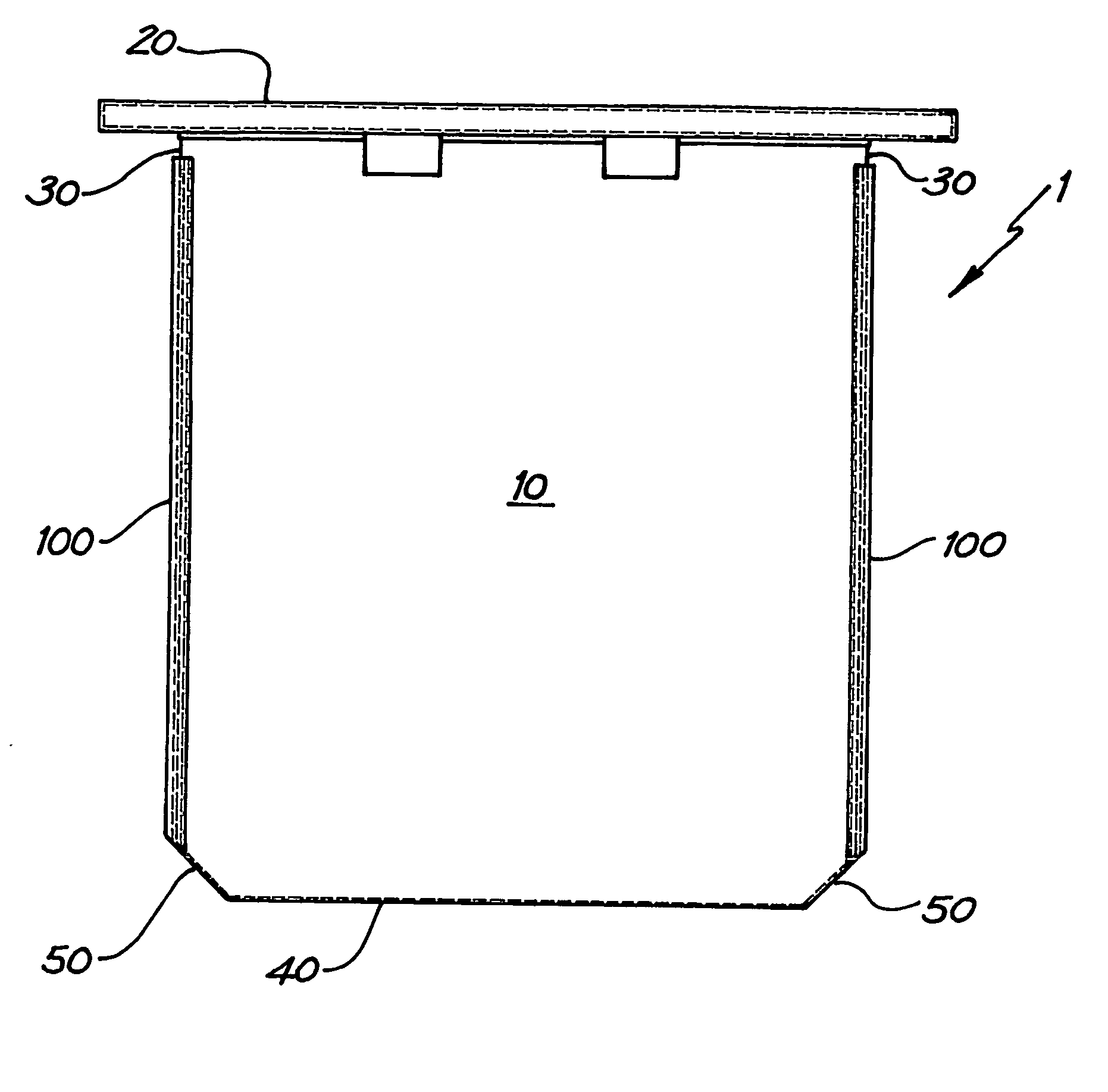

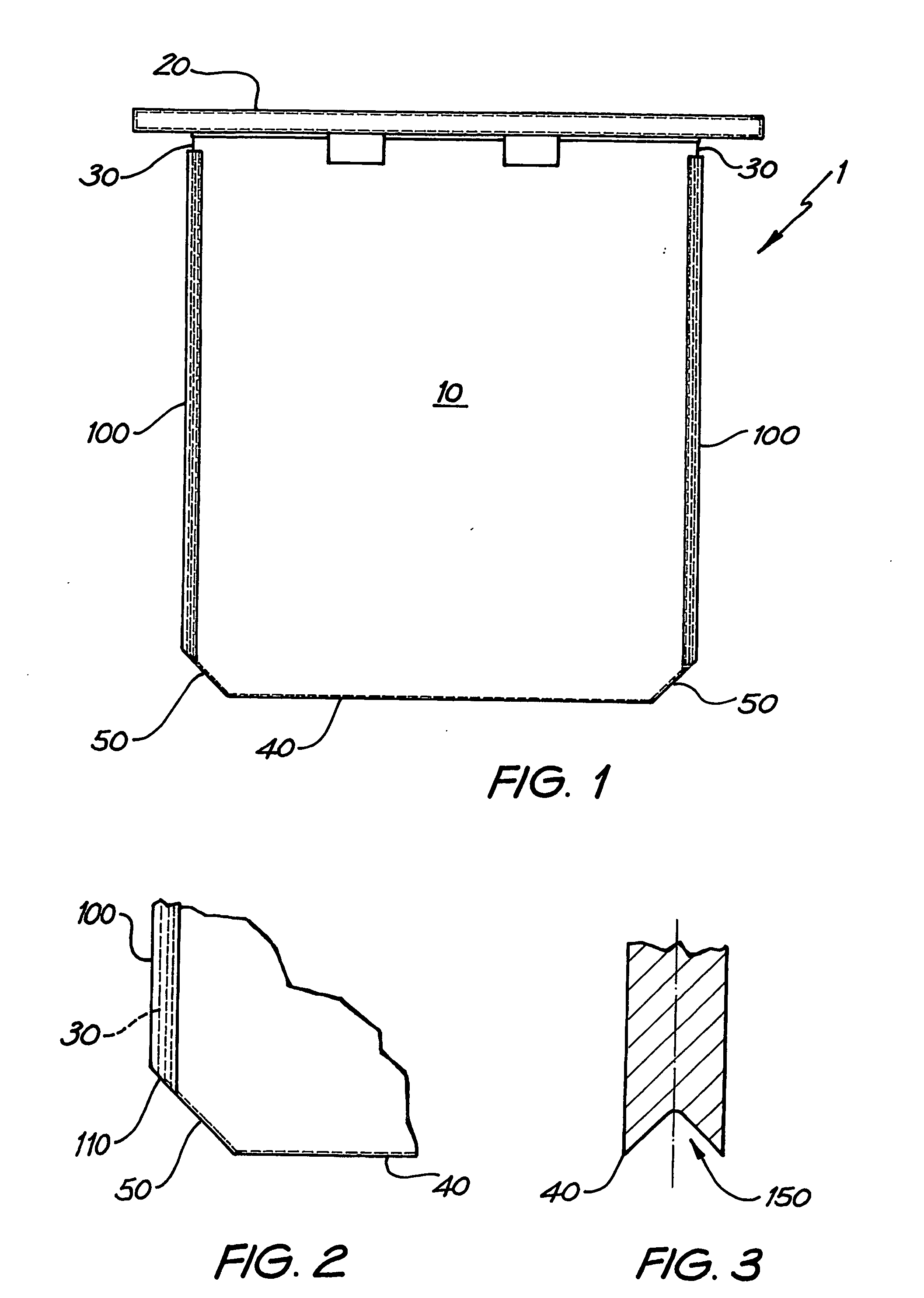

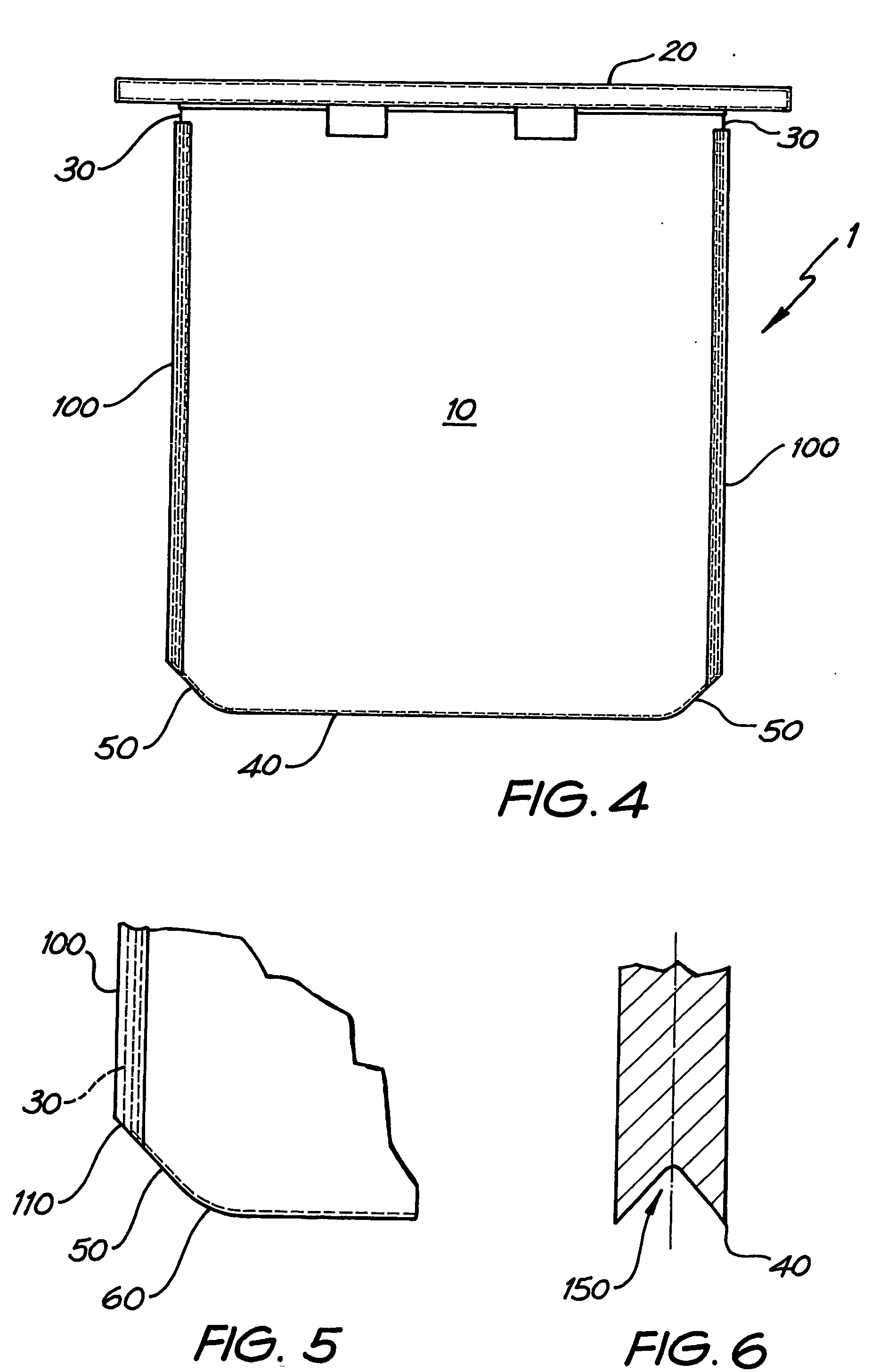

[0026] Referring firstly to FIGS. 1 and 2, the cathode plate 1 comprises a cathode blade 10 and hanger bar 20 connected along the top edge of the blade 10. As is well known in the art, the hanger bar 20 supports the blade 10 within an electrolytic bath and provides electric current to the blade for deposition of metal.

[0027] On the other three sides, the area of the blade is defined by side edges 30 and horizontal bottom edge 40. The periphery of the blade 10 is defined by hanger bar 20 at the upper periphery, side edges 30, at the side peripheries and bottom edge 40 at the lower periphery. The side edges extend downwardly from hanger bar 20 but terminate short of the lower periphery. Bottom edge 40 similarly terminates short of the side periphery defined by side edges 30. Either end of the horizontal edge 40 is joined to its respective side edge 30 by means of corner edge portion 50. In the embodiment shown, corner edge portion 50 is a straight edge between bottom edge 40 and side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap