Vacuum cleaner having brush motor using deceleration rate

a vacuum cleaner and motor technology, applied in the direction of machines/engines, carpet cleaners, bowling games, etc., can solve the problems of increasing the rotation speed of the motor, increasing the number of sparks generated, and damage to the motor, so as to achieve competitive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

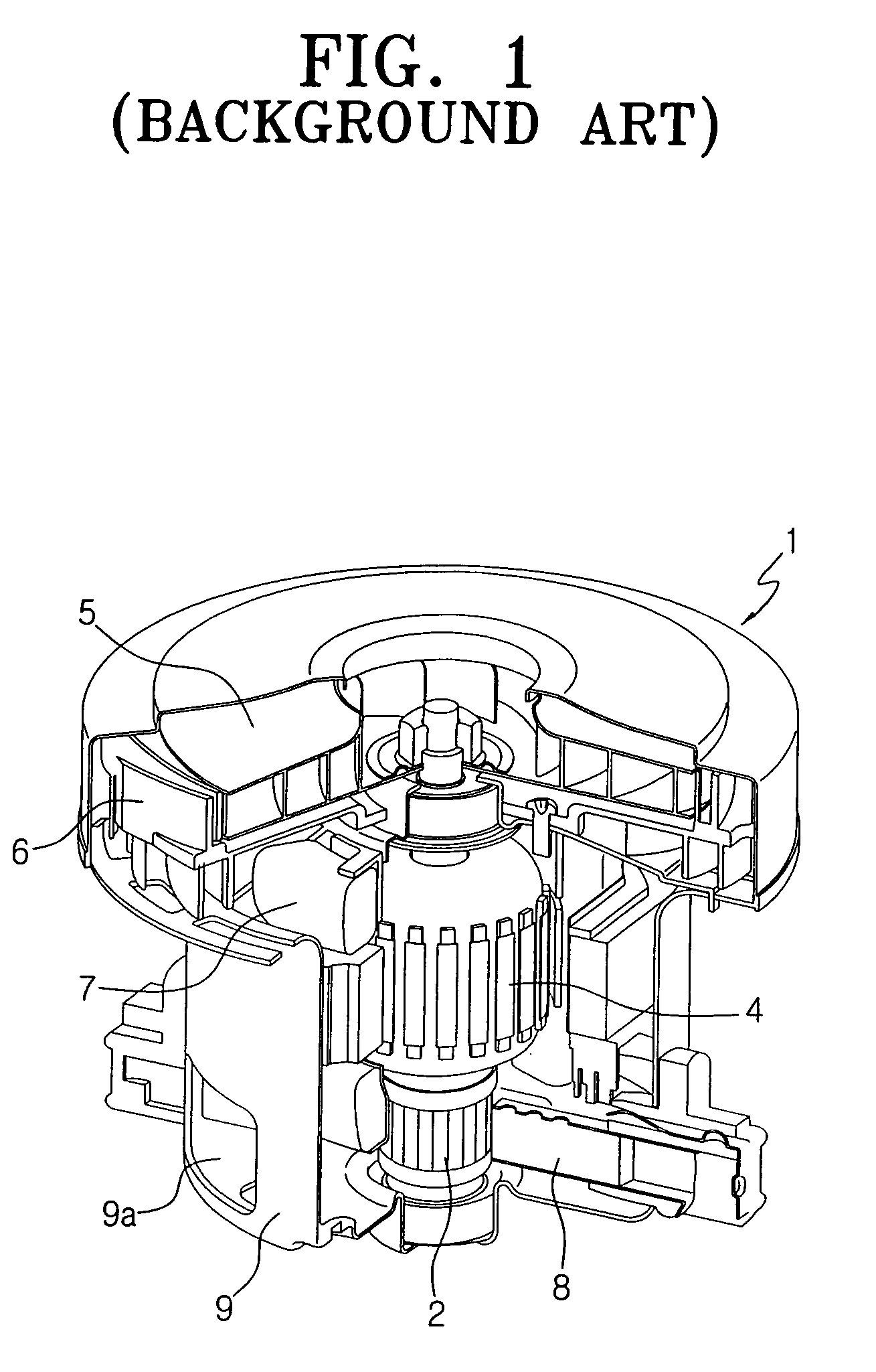

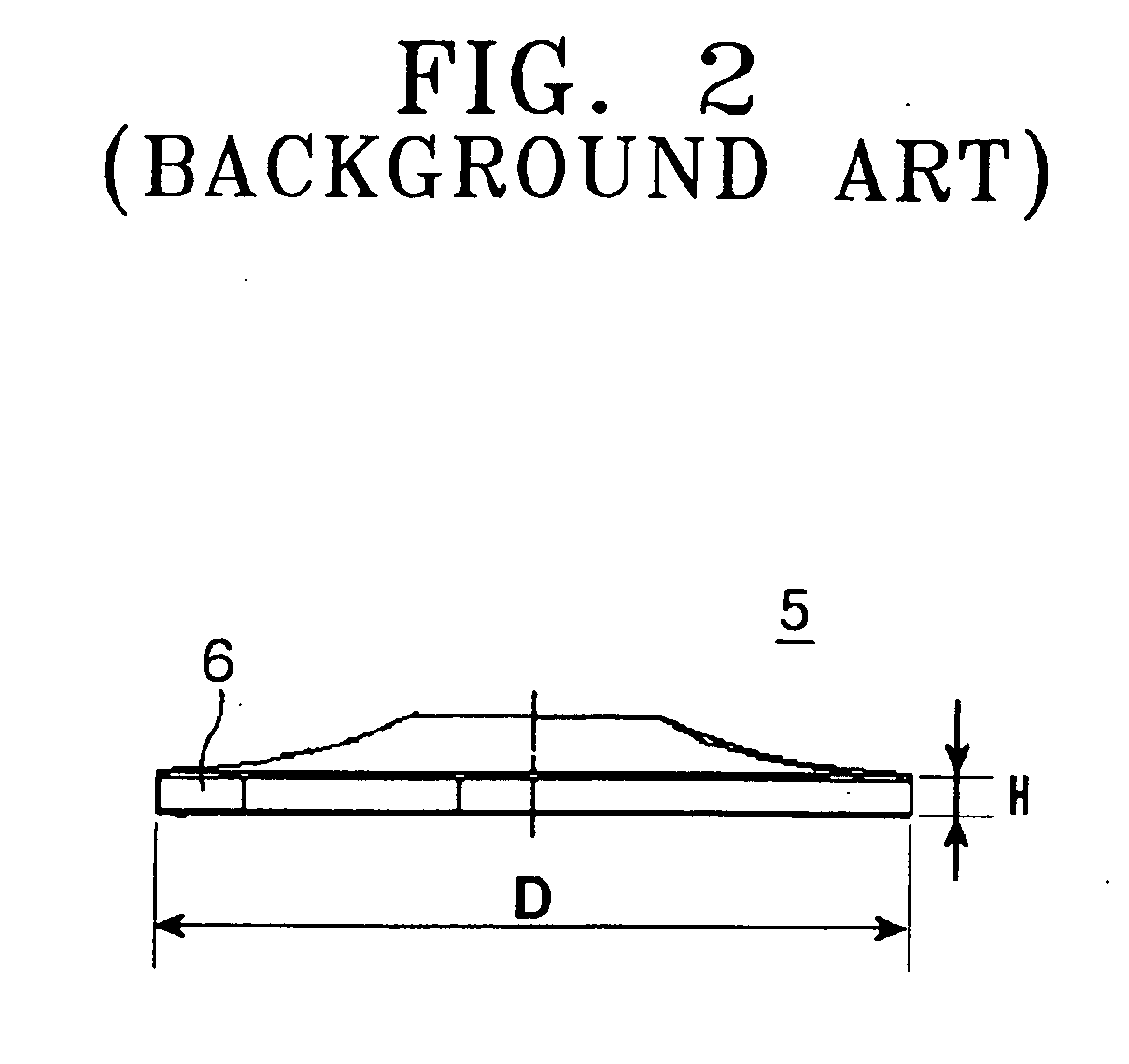

[0031] A brush motor of a vacuum cleaner using a deceleration rate in accordance with the first non-limiting embodiment of the present invention will now be described in detail with reference to the accompanying drawings. FIG. 4 is a schematic perspective view of a non-limiting example of a vacuum cleaner with a brush motor using a deceleration rate in accordance with the first embodiment. FIG. 5 is a schematic cross-sectional view that illustrates a non-limiting example the brush motor of the vacuum cleaner using the deceleration rate.

[0032] According to the first embodiment of the present invention, the vacuum cleaner with the brush motor using the deceleration rate may include a cleaner main body 20, a flexible hose 30, a suction brush 40, and a motor 50 positioned at the main body 20.

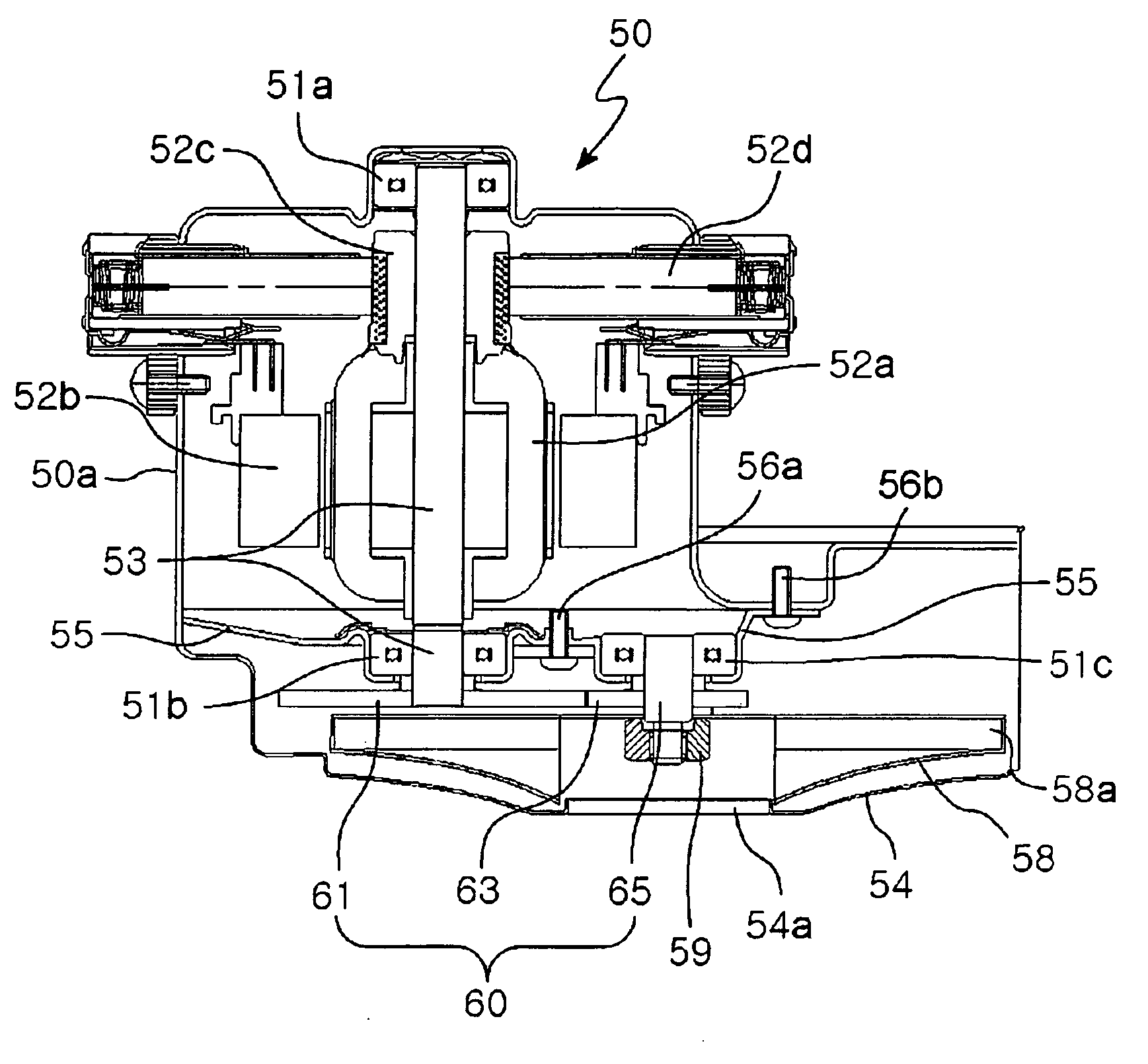

[0033] As illustrated in FIG. 5, the vacuum cleaner may include a decelerating unit 60 that connects a driving shaft 53 of the motor 50 with an impeller 58 to transfer the rotation force of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com