Bobbin changer apparatus for sewing machine

a technology for changing bobbins and sewing machines, applied in sewing apparatuses, loop takers, textiles and paper, etc., can solve the problems of high cost, high labor intensity, and a large amount of time and labor in the manufacture of component parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] [General External Appearance of Multi-Head Embroidery Sewing Machine]

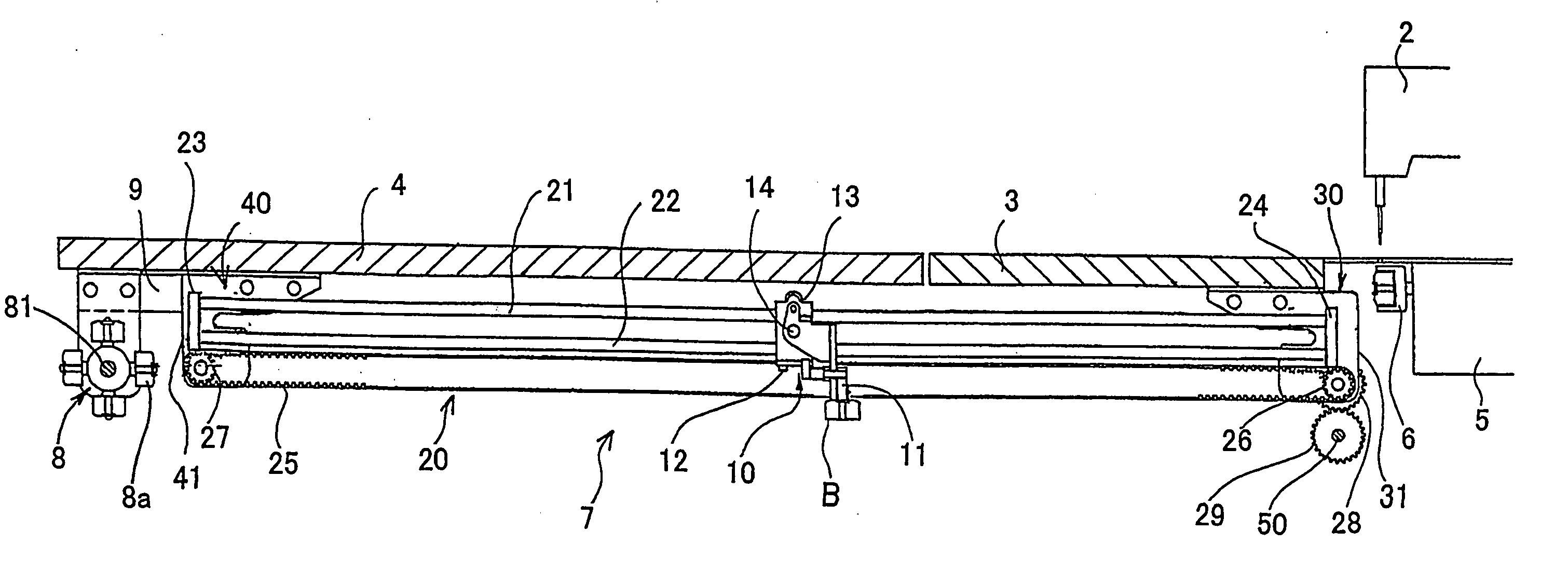

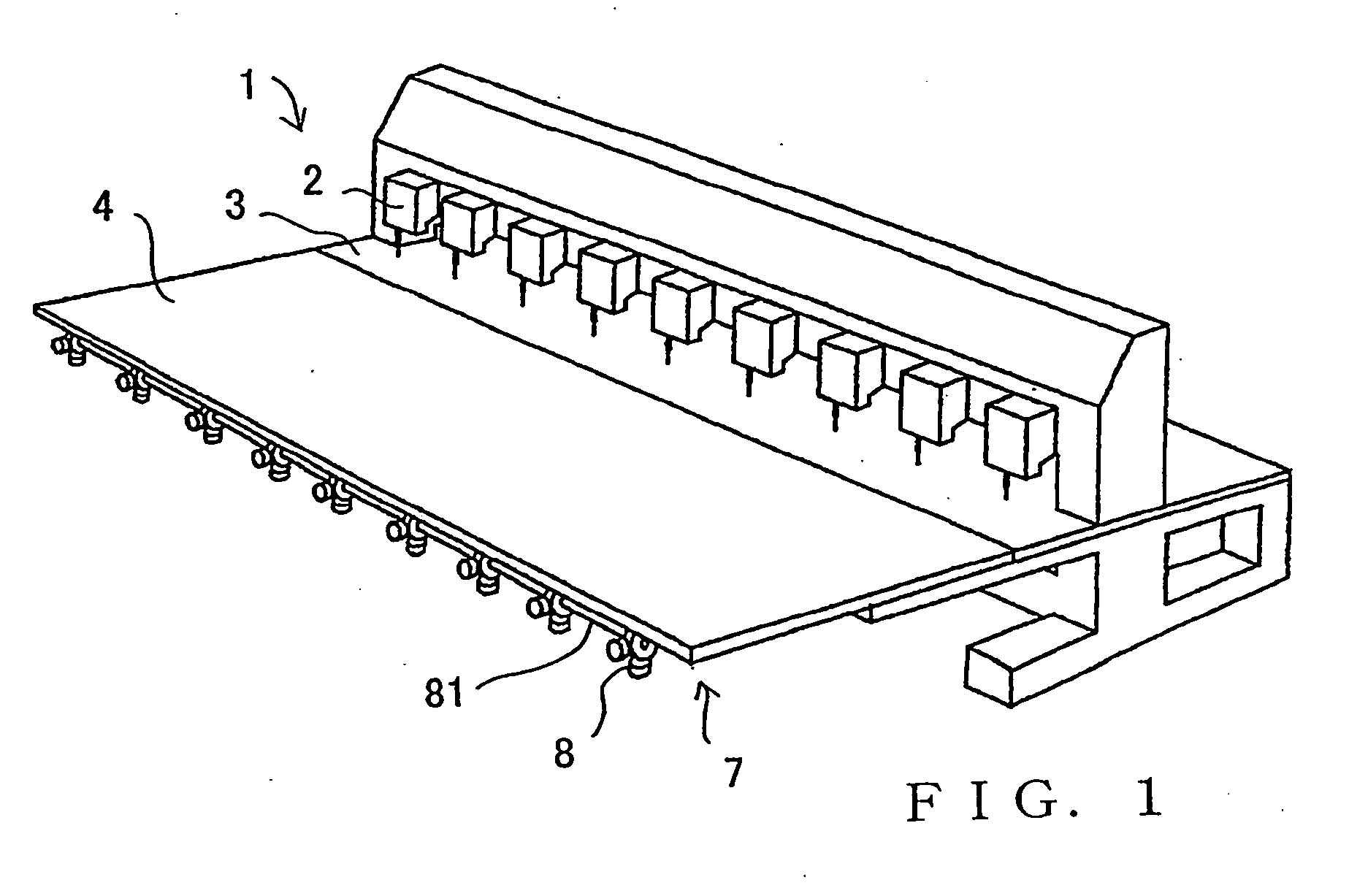

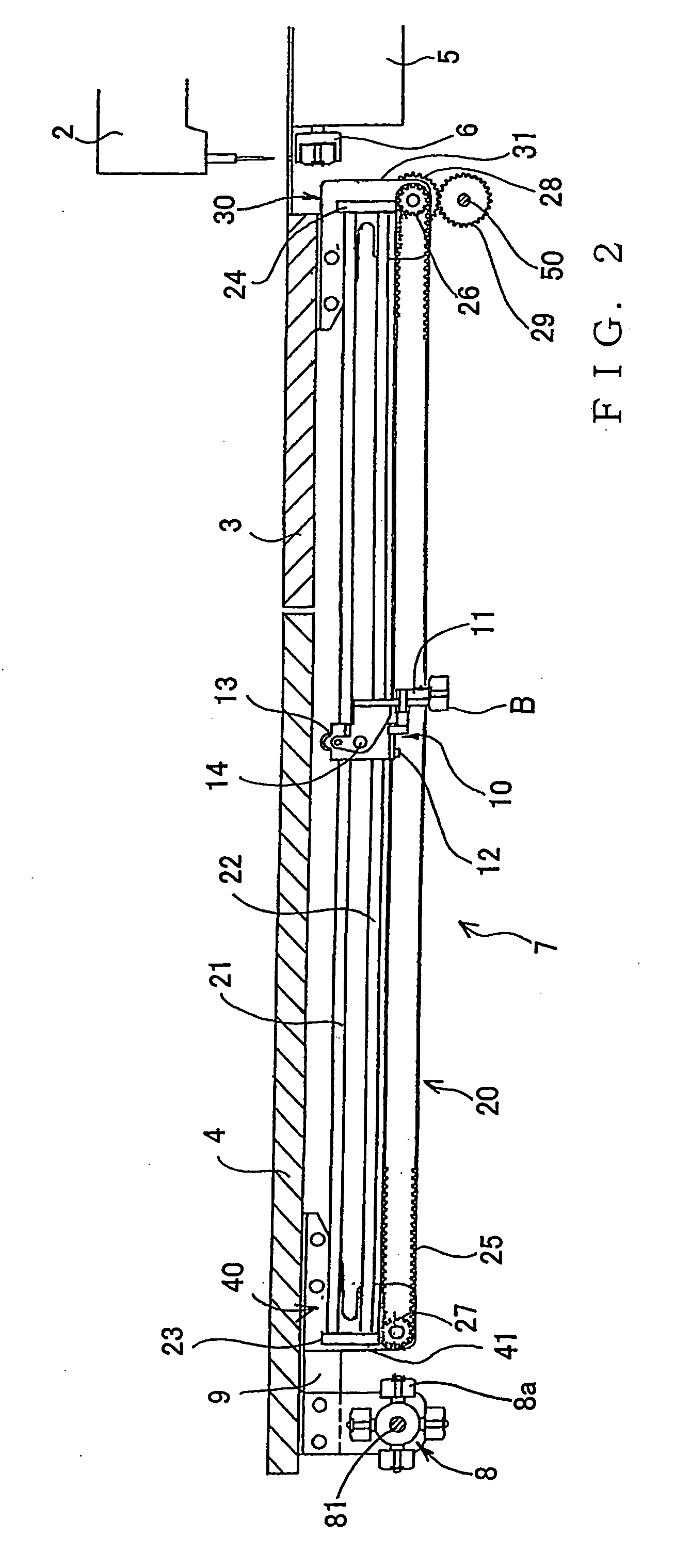

[0029]FIG. 1 is a schematic view showing an example external appearance of a multi-head embroidery sewing machine employing a bobbin changer apparatus in accordance with the present invention.

[0030] As known in the art, the multi-head embroidery sewing machine 1 at least includes a plurality of machine heads 2, rotary hook bases 5 (FIG. 2) provided beneath a main (body) sewing table 3 in corresponding relation to the machine heads 2, rotary hooks 6 (FIG. 2) provided on the individual hook bases. Extension sewing table 4 is detachably attached to a front edge portion of the main sewing table 3. Further, although not shown for simplification of illustration, an embroidery frame drive mechanism is provided on the sewing tables. Further, the bobbin changer apparatus 7 according to an embodiment of the present invention is provided for each of the rotary hooks 6 corresponding to the machine heads 2. Although the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com