Fill port for a self-priming centrifugal pump, with safety device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

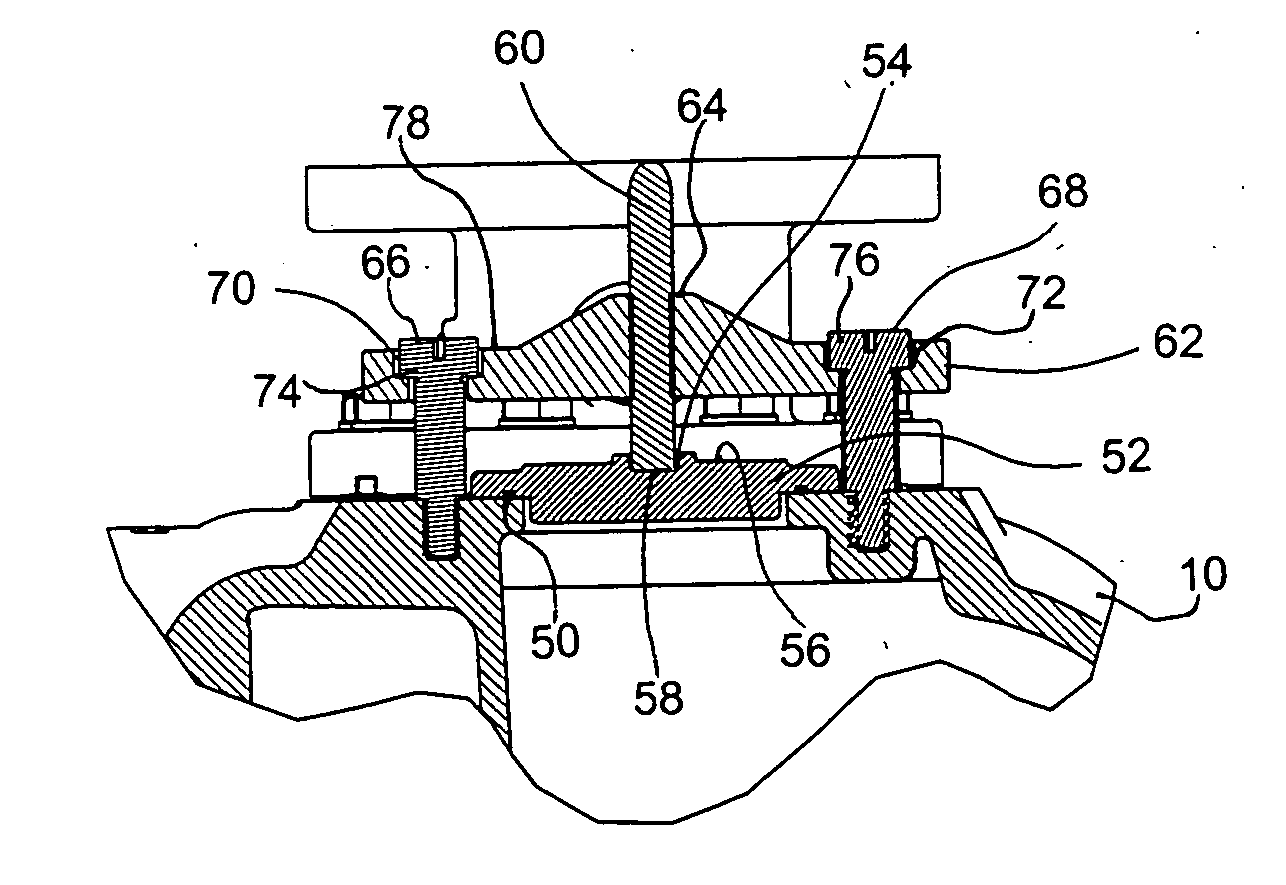

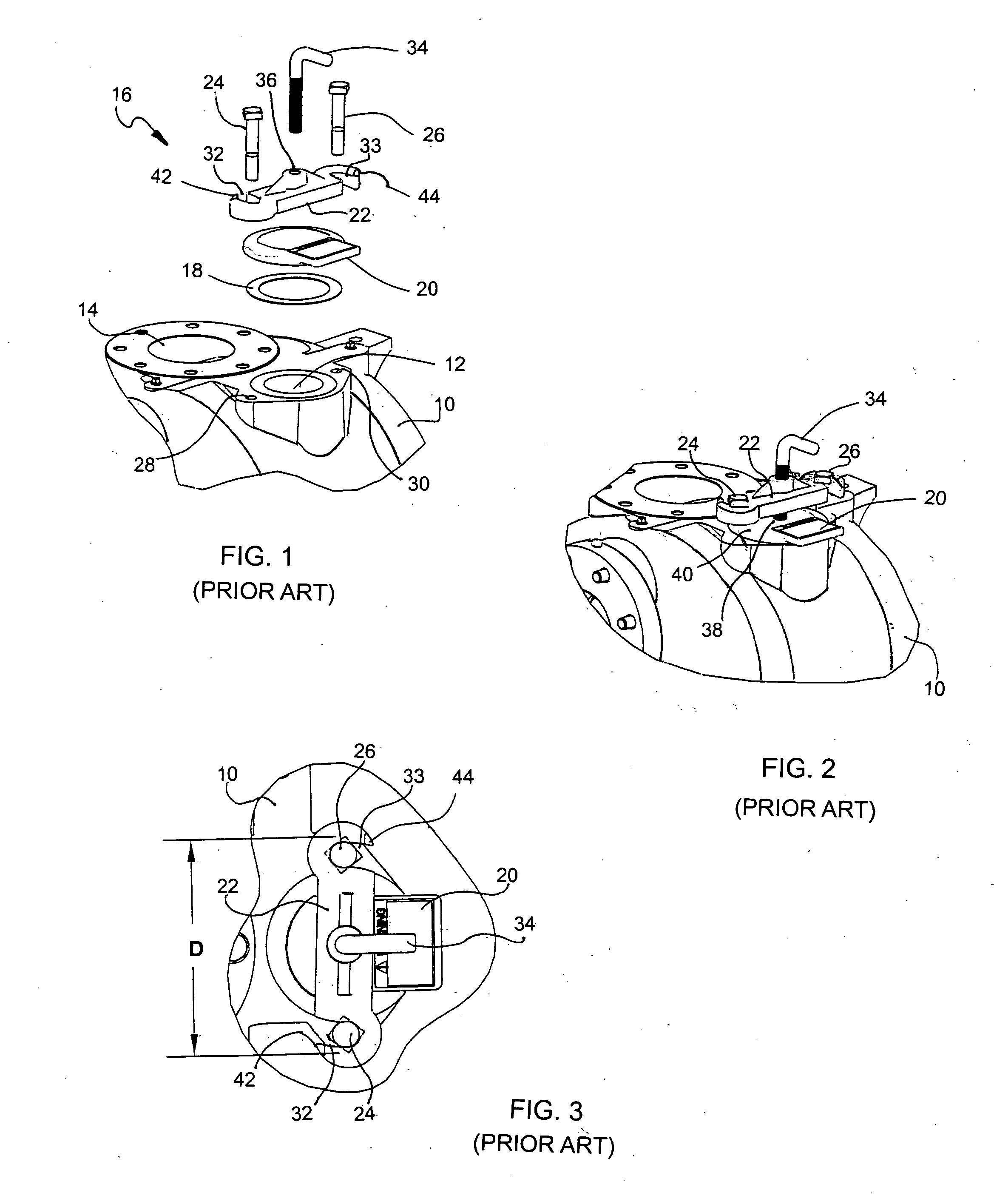

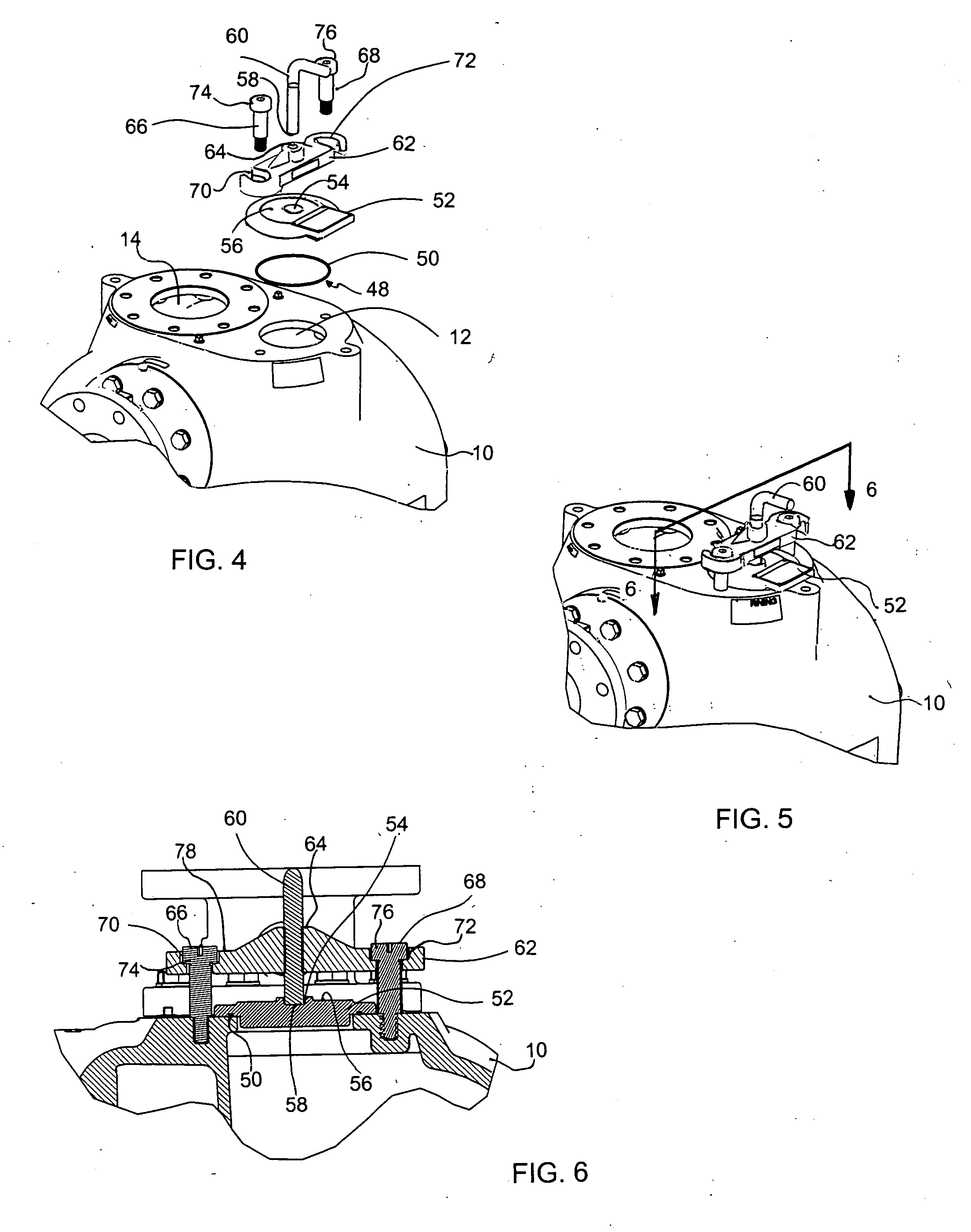

[0022] The fill port safety device of the present invention is best illustrated by a comparison with conventional fill port covers, an example of which is depicted in FIGS. 1-3. In particular, FIG. 1 illustrates the top of a pump casing 10 having a fill port 12 positioned near the outlet 14 of the pump. The prior art closure 16 of the fill port 12 comprises a flattened gasket 18 that is sized to fit about the fill port 12 opening and is positioned to be held in place by a fill port cover 20. A retaining clamp 22 is provided for positioning over the fill port cover 20 and is secured to the pump casing 10 by square-head bolts 24, 26 that threadingly connect to threaded holes 28, 30 in the pump casing 10 located on either side of the fill port 12. The retaining clamp 22 is configured with U-shaped openings 32, 33 at either end of the clamp 22 to receive the bolts 24,26.

[0023] An L-shaped anchor bolt 34 is threaded through a central opening 36 in the retaining clamp 22. As best seen in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com