Rubberized roof underlayment

a technology of roof and underlayment, which is applied in the direction of transportation and packaging, roads, traffic signals, etc., can solve the problems of product stickyness, water infiltration not prevented, and other prior art shingle underlayment products also suffer from the same problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention features a novel underlayment product which will be relatively inexpensive and replace prior art products such as “tar paper” or “felt paper”. The present invention provides an underlayment product with a top surface that can be walked on and will not slide under foot, and wherein the product will not stick to itself or the roof. In addition, the present invention has “cold” flow properties and elongate and recovery properties which allow it to reseal around nail or puncture holes.

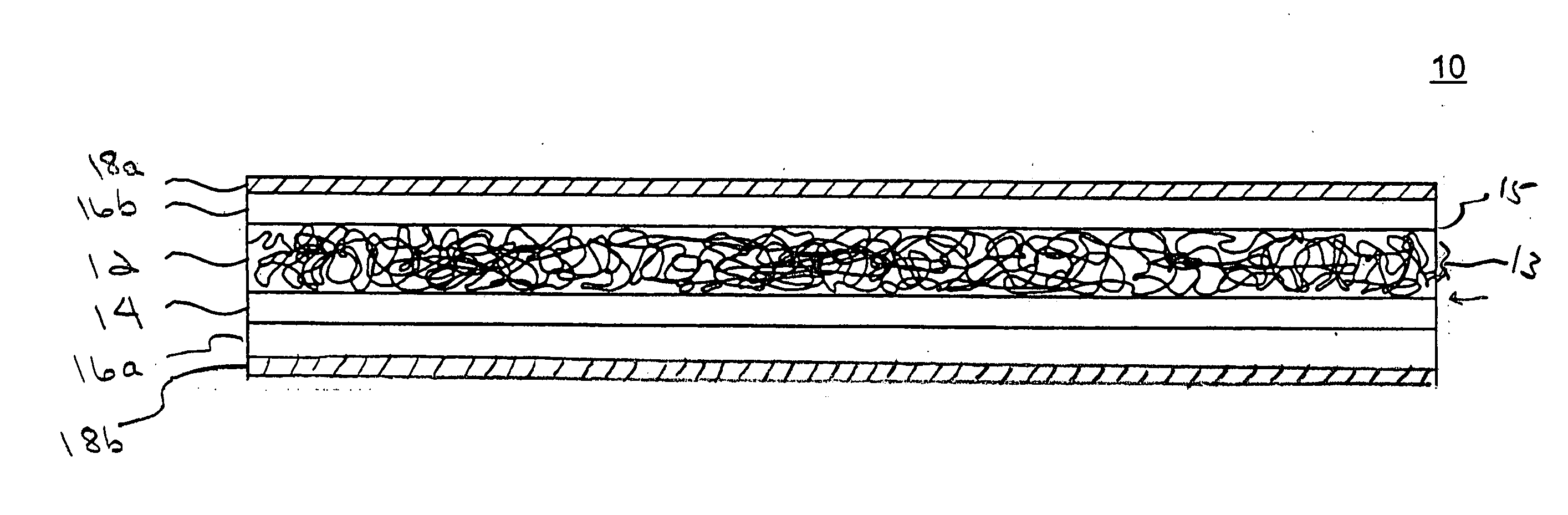

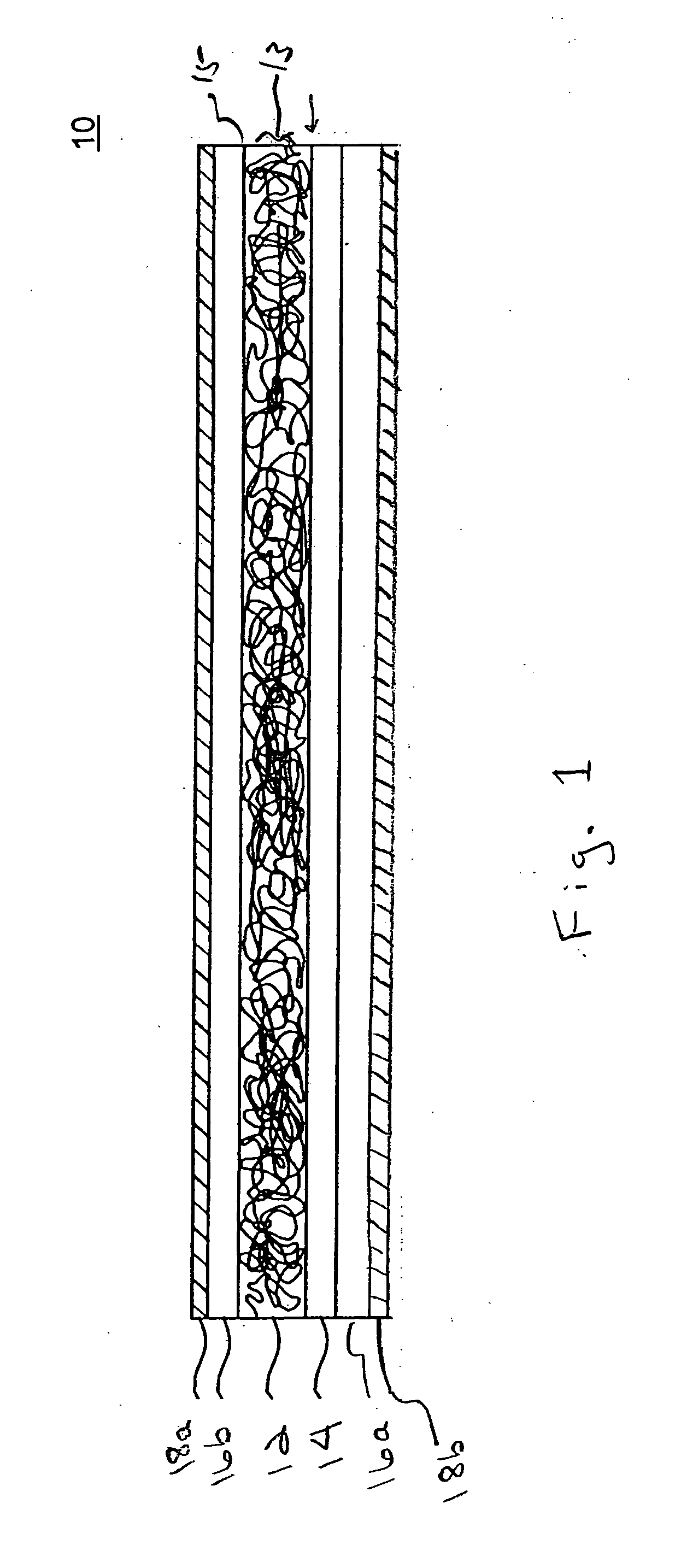

[0016] The underlayment 10, FIG. 1, in accordance with the present invention includes a fibrous mat 12 disposed in the center of the underlayment. Examples of and equivalents for the fibrous mat 12 are disclosed in U.S. Pat. Nos. 6,531,200 and 6,296,912 assigned to the assignee of the present invention and incorporated fully herein by reference.

[0017] The fibrous mat 12 is first coated proximate one side with a rubberized asphalt layer 14. The rubberized asphalt layer 14 typi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com