Snow-Blower

a technology of snowblower and shovel, which is applied in the field of snowblower, can solve the problems of laborious snow removal, low physical strength, and decreased number of young people, and achieve the effect of excellent solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

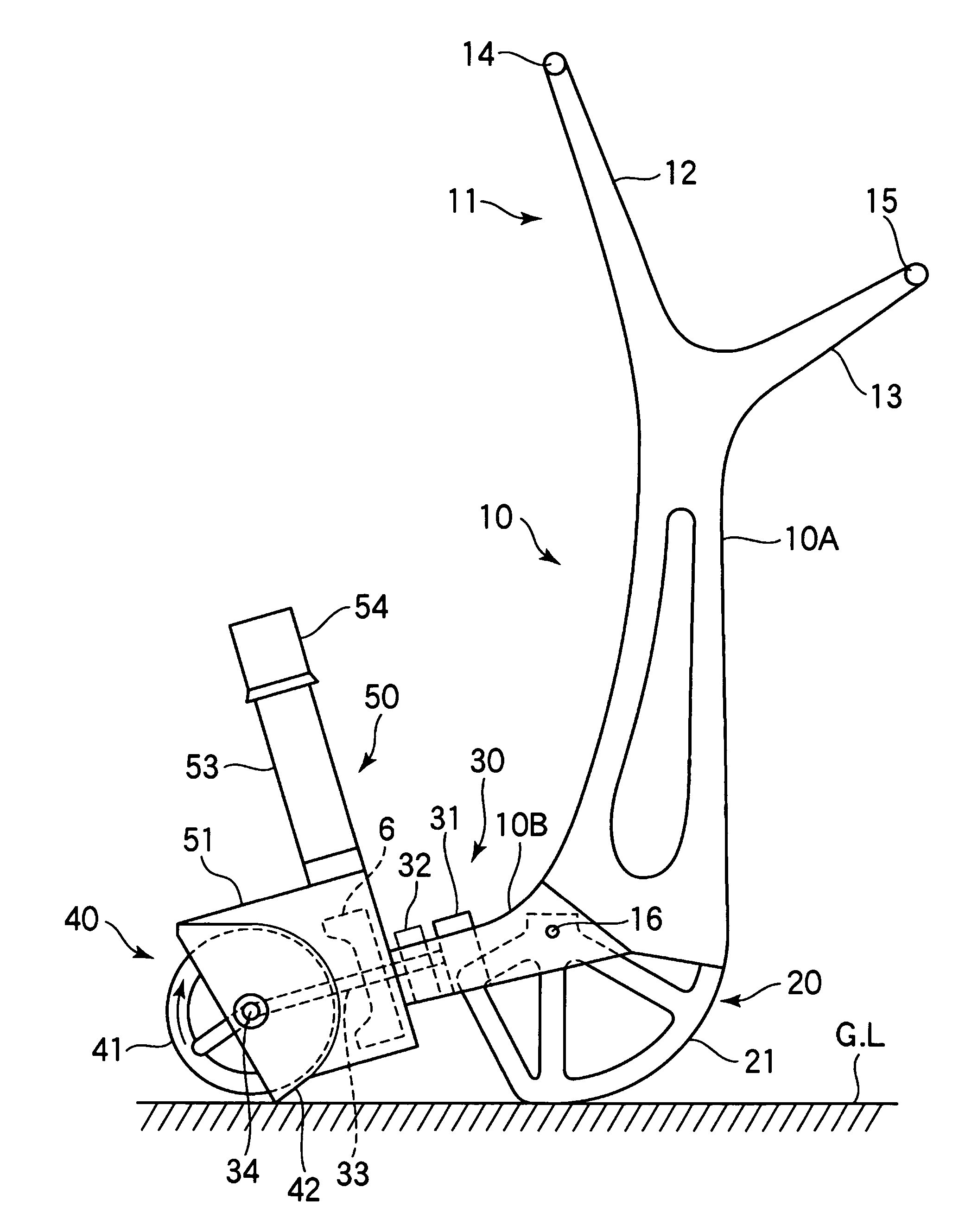

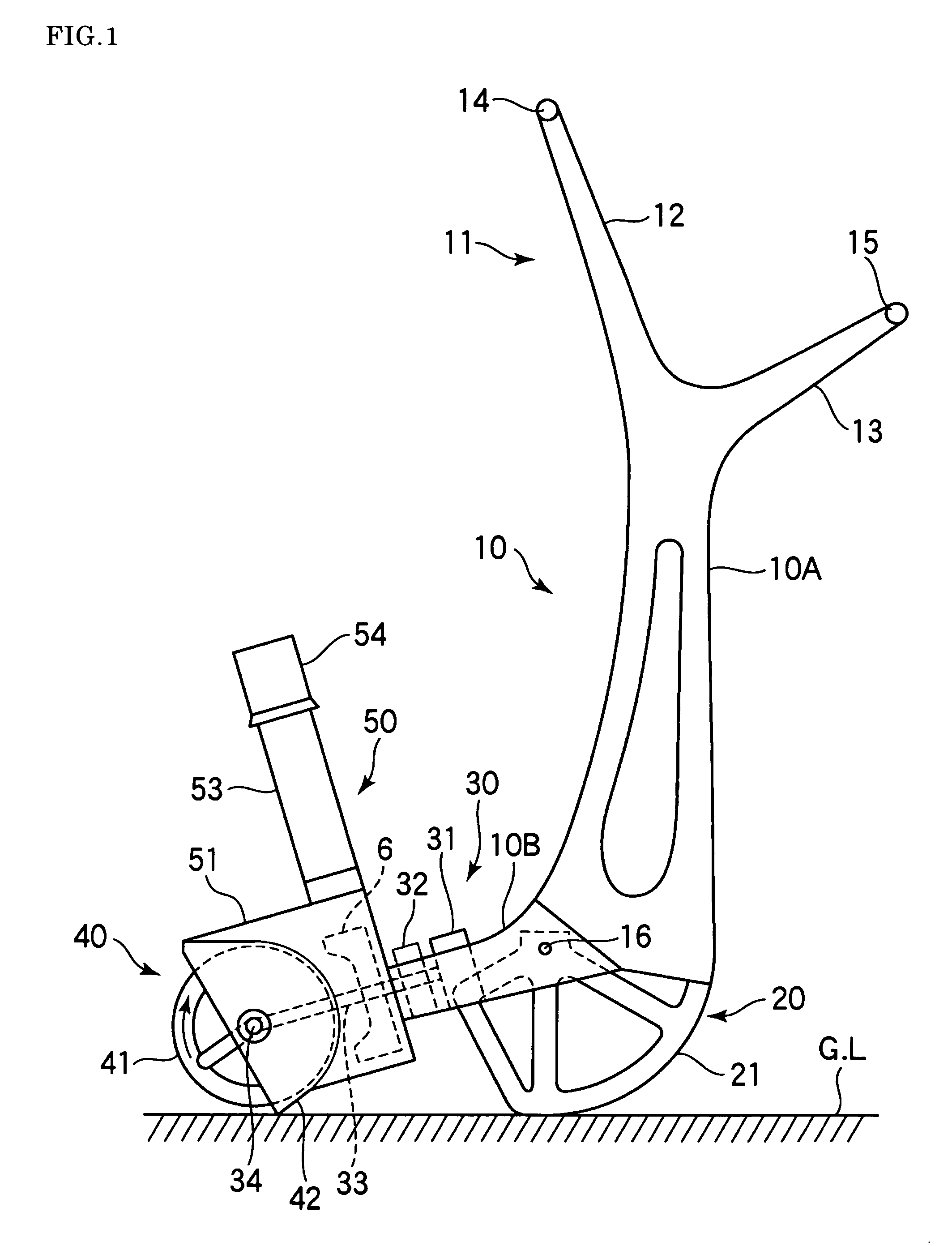

example 1

[0038] A snow-blower according to the first embodiment was employed, where the fulcrum 16 of a frame 10 was positioned 213 mm above ground level, and arc-shaped sliders 21 having a radius of 213 mm (as measured from the fulcrum serving as the center of the sliders) were provided such that the frame 10 was swiveled about the fulcrum 16. An auger having a diameter of 220 mm was provided at a position 410 mm in front of the fulcrum 16, and a lower handlebar 15 was provided at a position 1,000 mm backward of the fulcrum 16. The angle of the lower handlebar 15 as viewed from the fulcrum 16 was set at 60° from the horizontal level. With this structure, when the auger is positioned on the ground, the level of the lower handlebar 1 is 1,079 mm, which is almost equal to human shoulder level. Subsequently, when the lower handlebar 15 is moved downward, and the frame 10 is swiveled by 60°, the lower handlebar 15 is positioned about 213 mm above ground level. At this time, an upper handlebar 14...

example 2

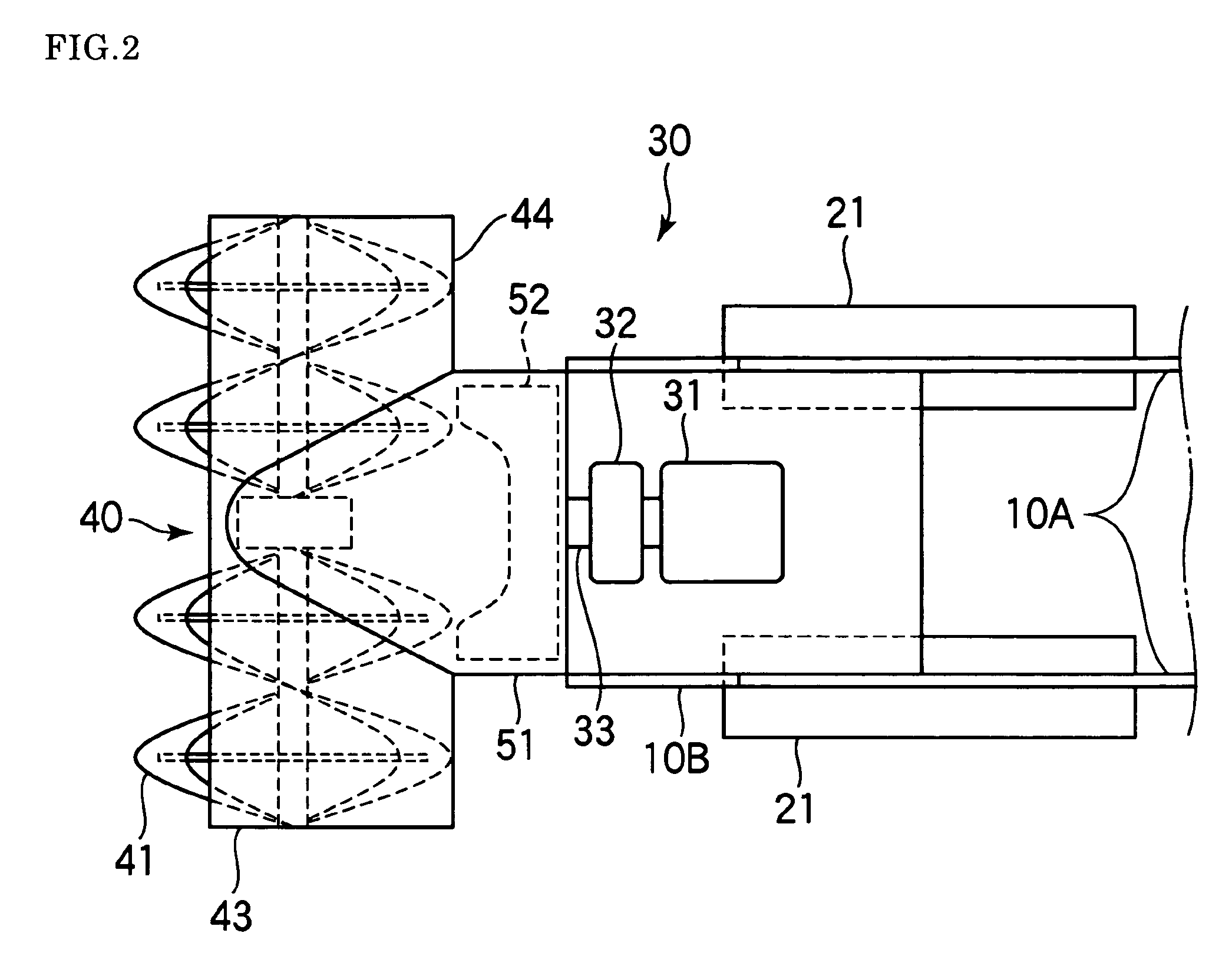

[0042] A snow-blower of the second embodiment was employed, where the diameter of a main auger was regulated to 140 mm; the diameter of a snow-collecting auger is regulated to 220 mm; the distance between the shaft of the main auger and that of the snow-collecting auger was regulated to 130 mm; the main auger and the snow-collecting auger were formed of spiral blades which are rotated in opposite directions; and a predetermined angle was provided between these augers such that the augers do not come into contact with each other. The snow-blower efficiently handled snow-banks having a height of about 10 cm. Values in parentheses of Table 1 correspond to the results obtained in the case of the snow-blower of Example 2. Conditions described in Table 1 other than the values shown in the parentheses are the same as those in the case of the snow-blower of Example 1. In the case of Example 2, the power source is the same as that employed in Example 1, but the weight of the snow-blower is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com