Sole configuration for metal wood golf club

a golf club and sole technology, applied in the field of golf clubs, can solve the problems of golf ball flying short of the intended target, low golf shot, loss of club head speed, etc., and achieve the effect of increasing the effective bounce of the club head, less friction, and increasing the speed of the club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Detailed embodiments of the present invention are disclosed herein. It should be understood that the disclosed embodiments are merely exemplary of the invention, which may be embodied in various forms. Therefore the details disclosed are not to be interpreted as limiting, but merely form a basis for the claims and as a basis for teaching one of ordinary skill in the art how to make and / or use the invention.

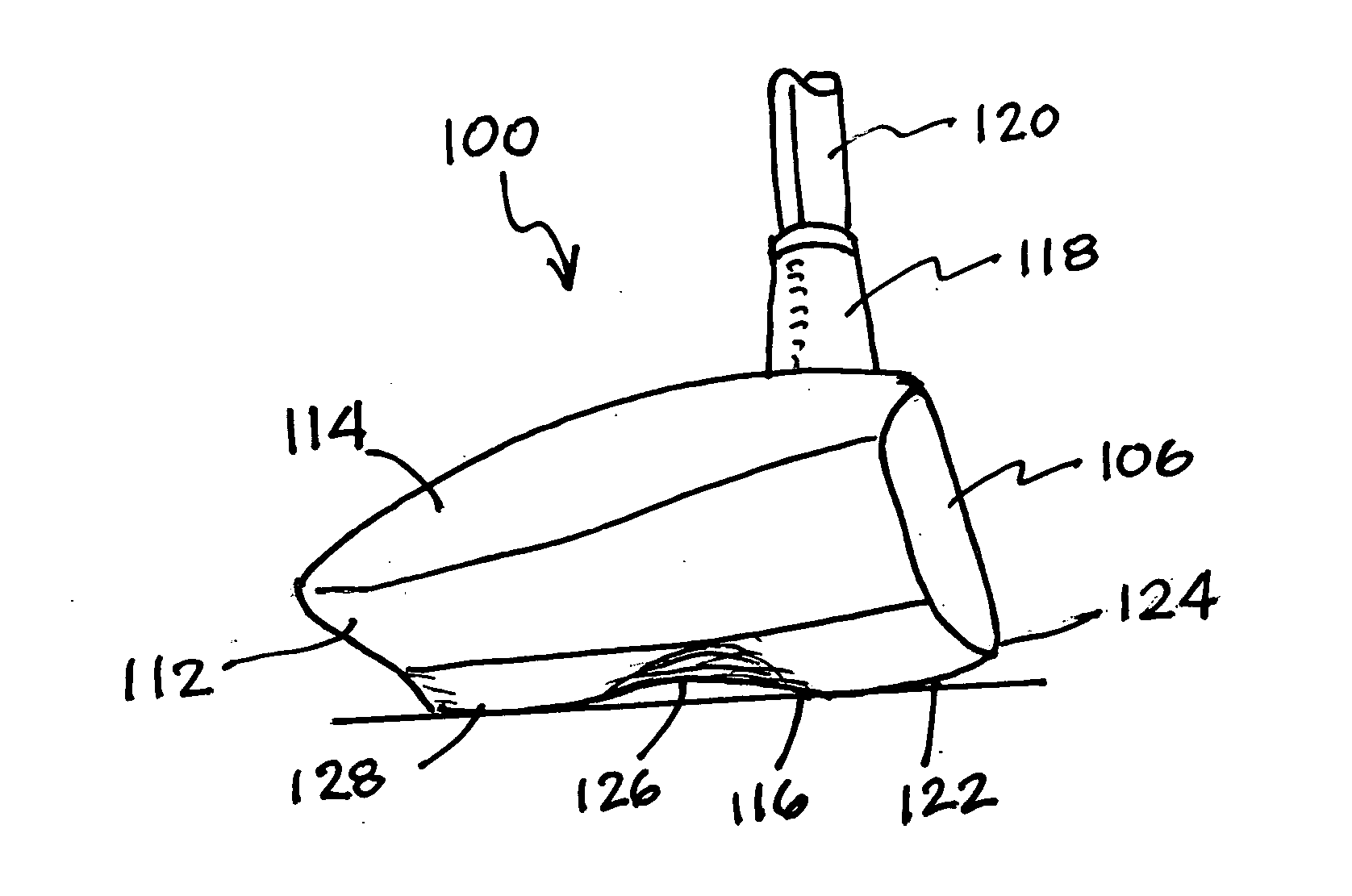

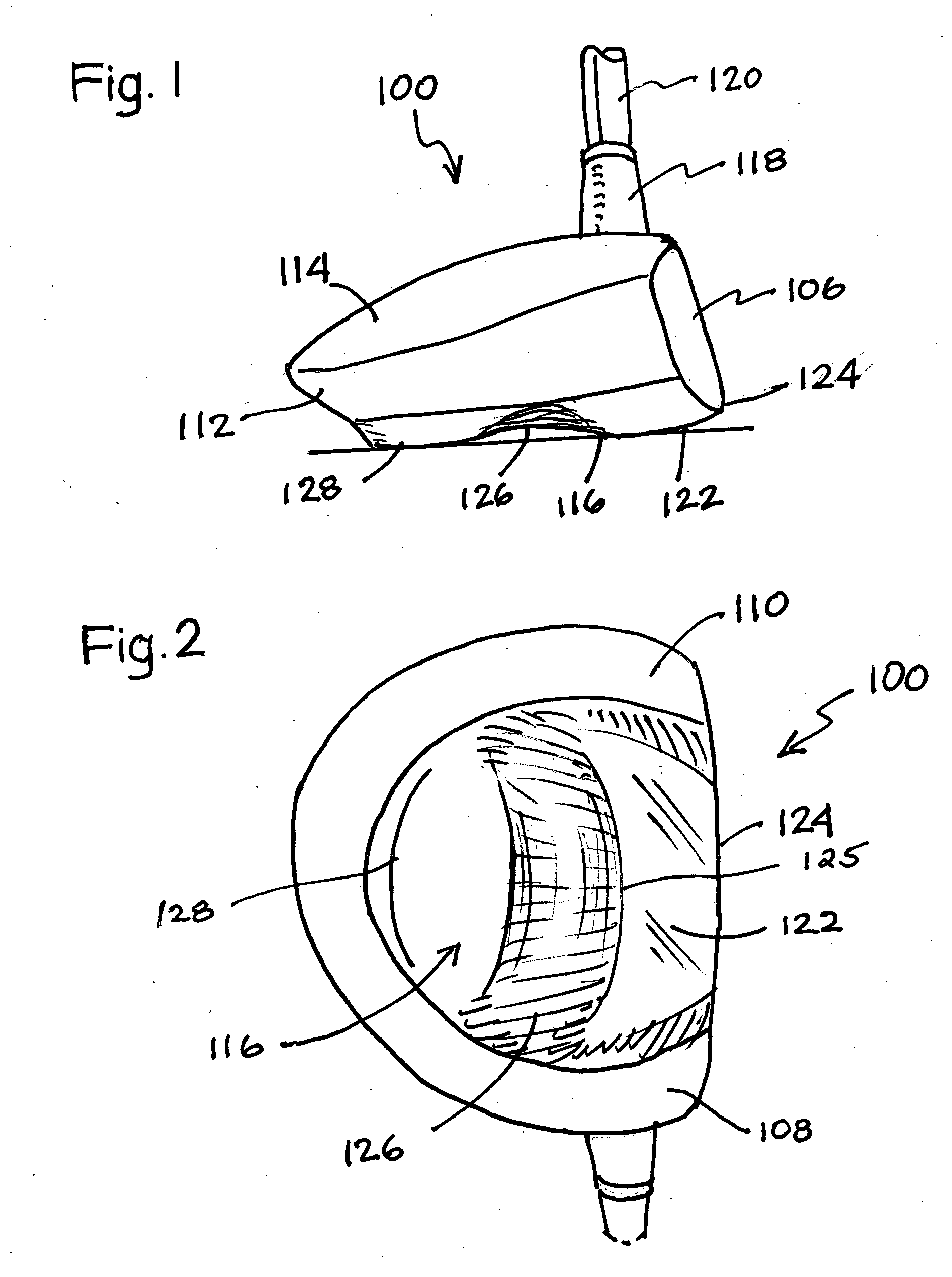

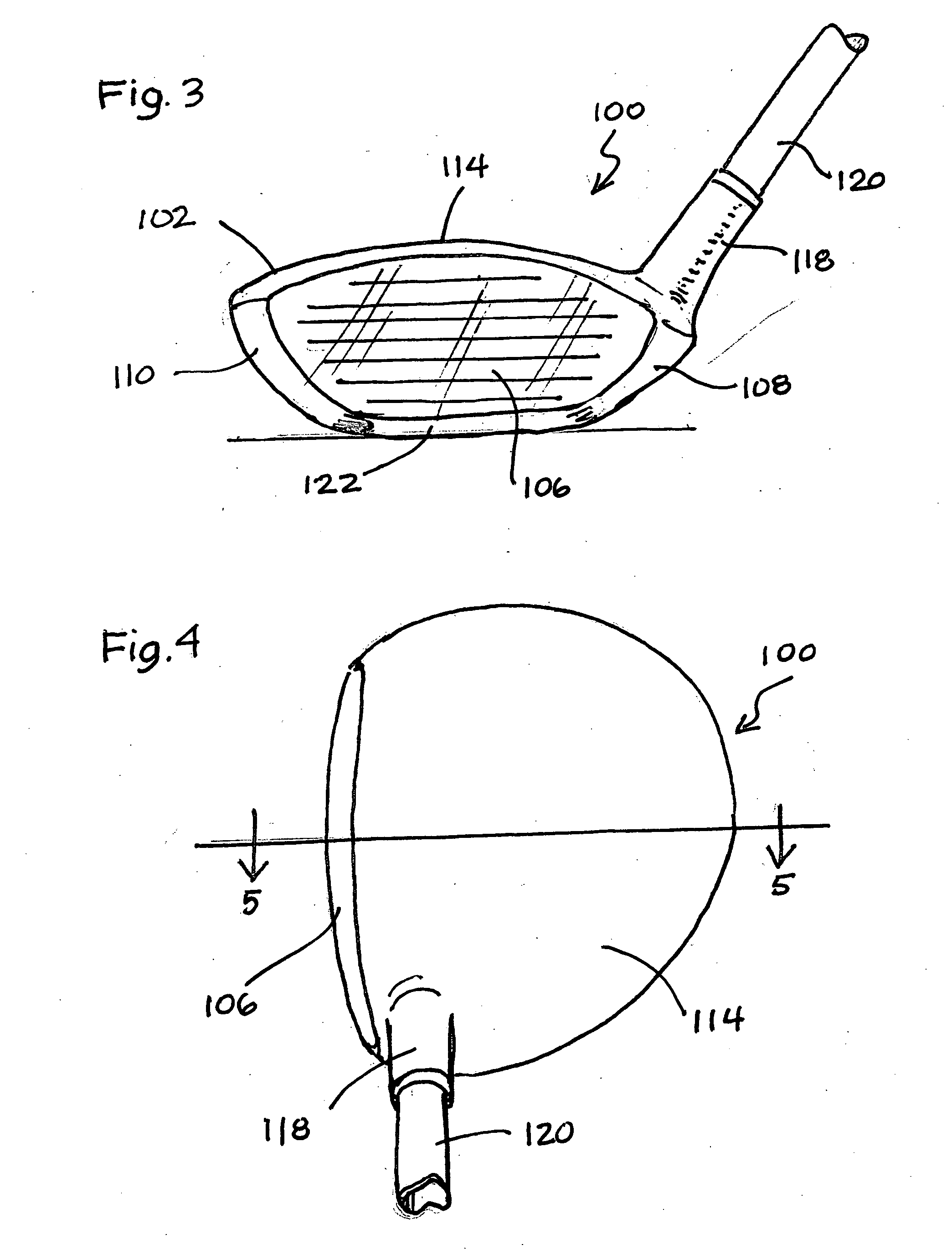

[0027] Referring to the drawings, FIGS. 1 to 5 disclose a metal wood golf club head100 of the present invention formed with a body portion 102 made of a hard metal material, forming a metal shell 104. The club head 100 includes a ball striking face 106, heel 108, toe 110, rear face 112, top crown 114, and bottom sole 116. The club head 100 is preferably formed with a hosel 118 connected to a conventional shaft 120 of any suitable length and handle or grip (not shown) on the upper end thereof.

[0028] The bottom sole 116 is formed in separate sections. A first forward sole s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com