Fluid measurement/division device and process

a technology of fluid measurement and division device, which is applied in the direction of liquid/fluent solid measurement, engine lubrication, and contracting/expanding measuring chamber. it can solve the problems of large and heavy description devices of traditional type, and the cost of traditional devices to constru

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

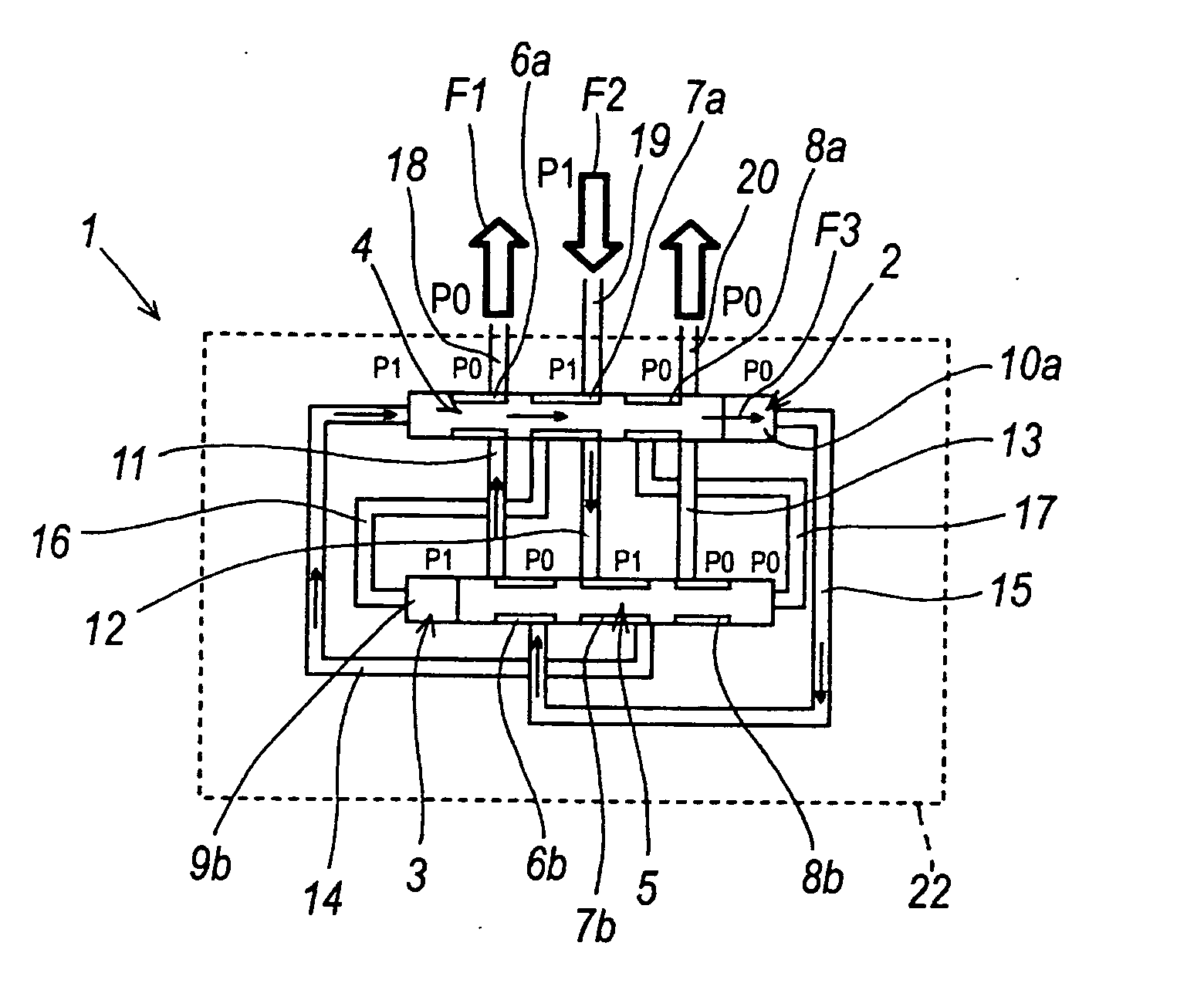

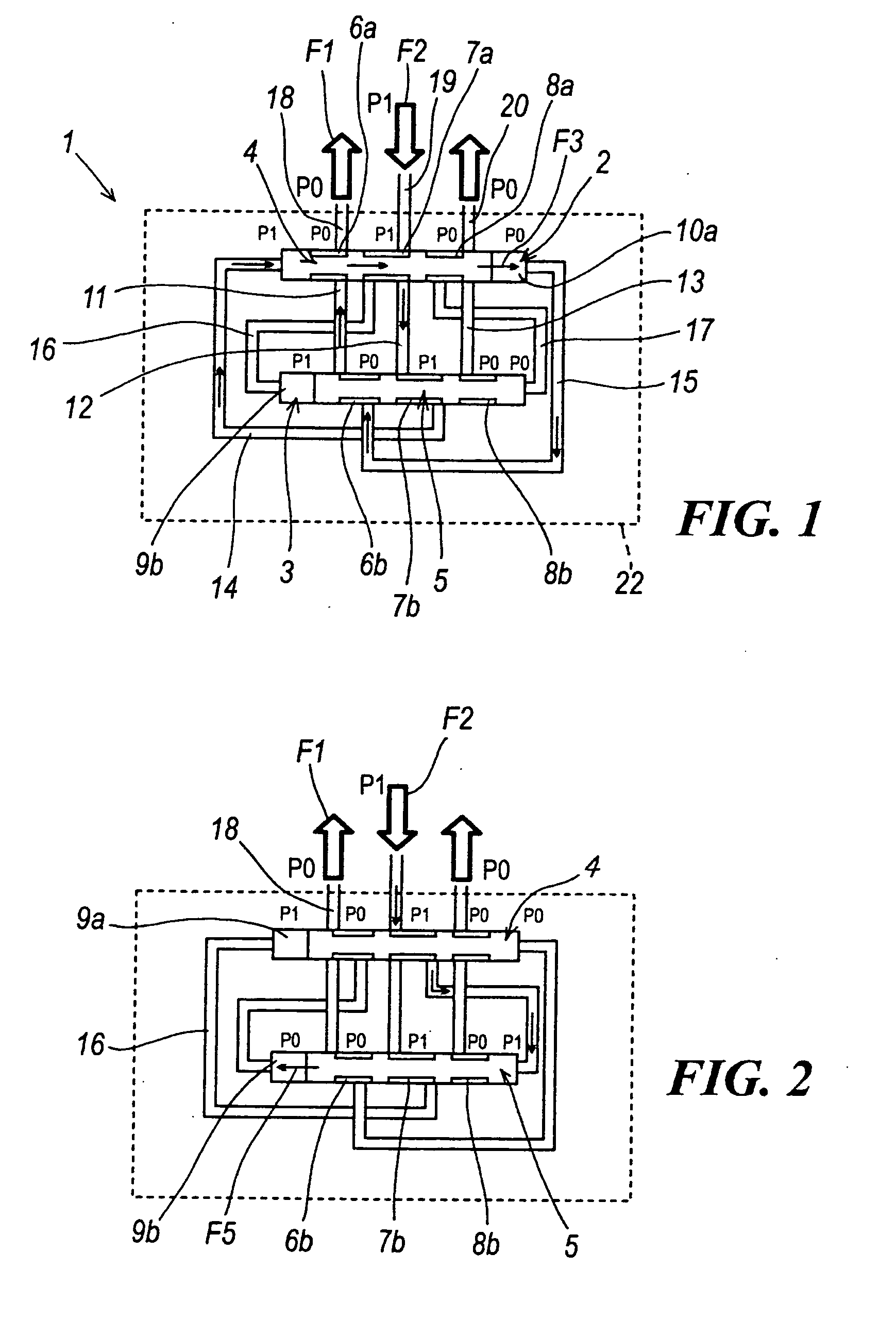

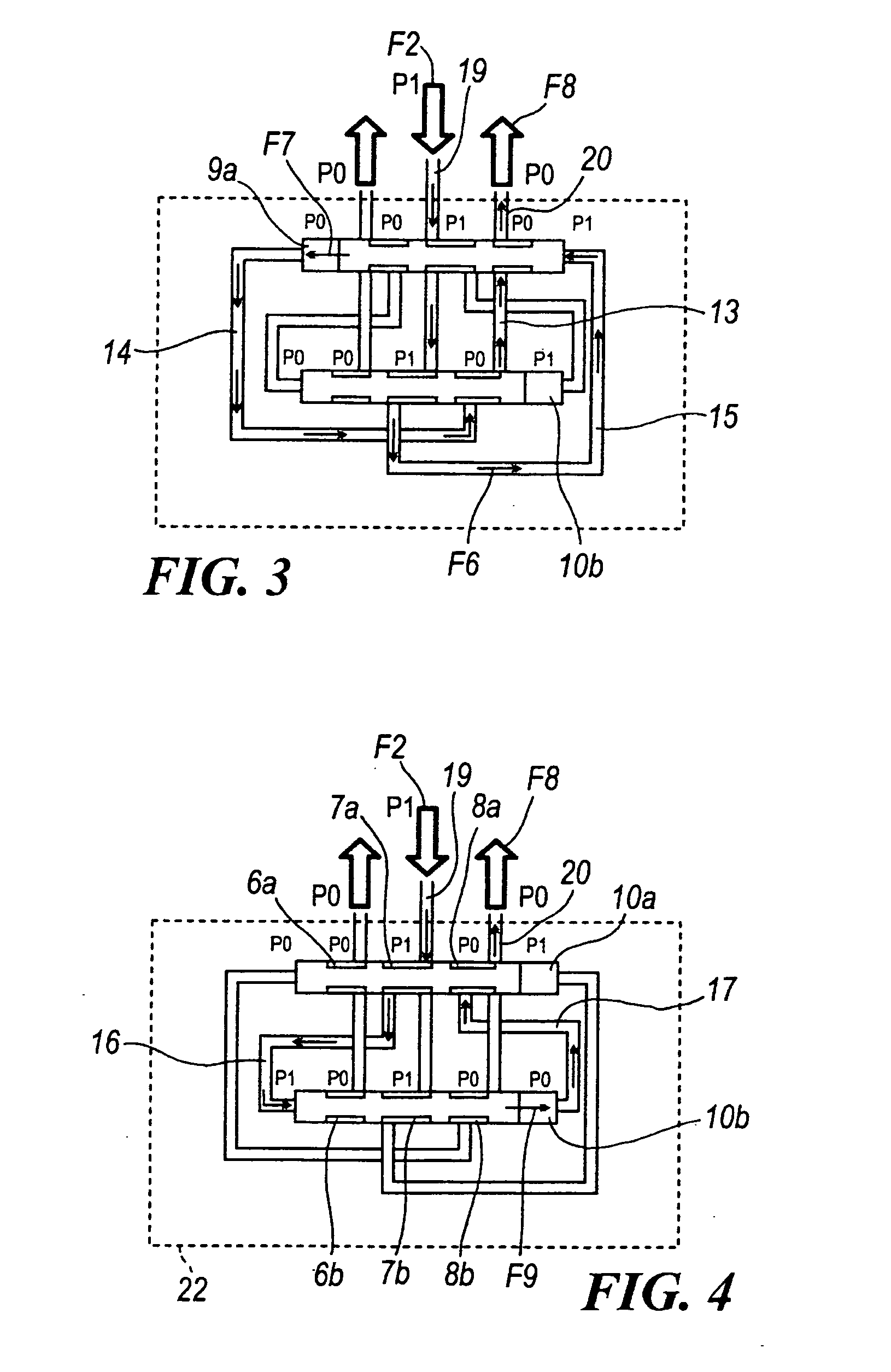

[0024] With reference to said figures, these show a fluid measurement / division device indicated overall by the reference numeral 1.

[0025] The device 1 comprises two cylinders 2, 3 in which a first and a second piston 4, 5 are slidably inserted.

[0026] Each of the two pistons 4, 5 operates alternately as a fluid dosing piston or as a piloting piston for the dosing piston.

[0027] The dosing piston dispenses fluid to the outside (by its movement), while the piloting piston defines the path for the fluid, which is directed towards the dosing piston to control its movement.

[0028] Advantageously, the first and second piston 4, 5 present reduced diameter regions which, together with the surface of the cylinders 2, 3, define three constant volume distribution chambers 6a, 7a, 8a and two variable volume pumping chambers 9a, 10a for the first cylinder 2, and three constant volume distribution chambers 6b, 7b, 8b and two variable volume pumping chambers 9b, 10b for the second cylinder 3.

[00...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap