Turbo compressor

a compressor and turbine technology, applied in the direction of machines/engines, liquid fuel engines, light and heating apparatus, etc., can solve the problems of large mechanical loss, short service life of bearings, and large mechanical loss, so as to increase the critical speed without, prolong the service life of bearings, and reduce mechanical losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0047]The description will be given below of an embodiment in accordance with the present invention.

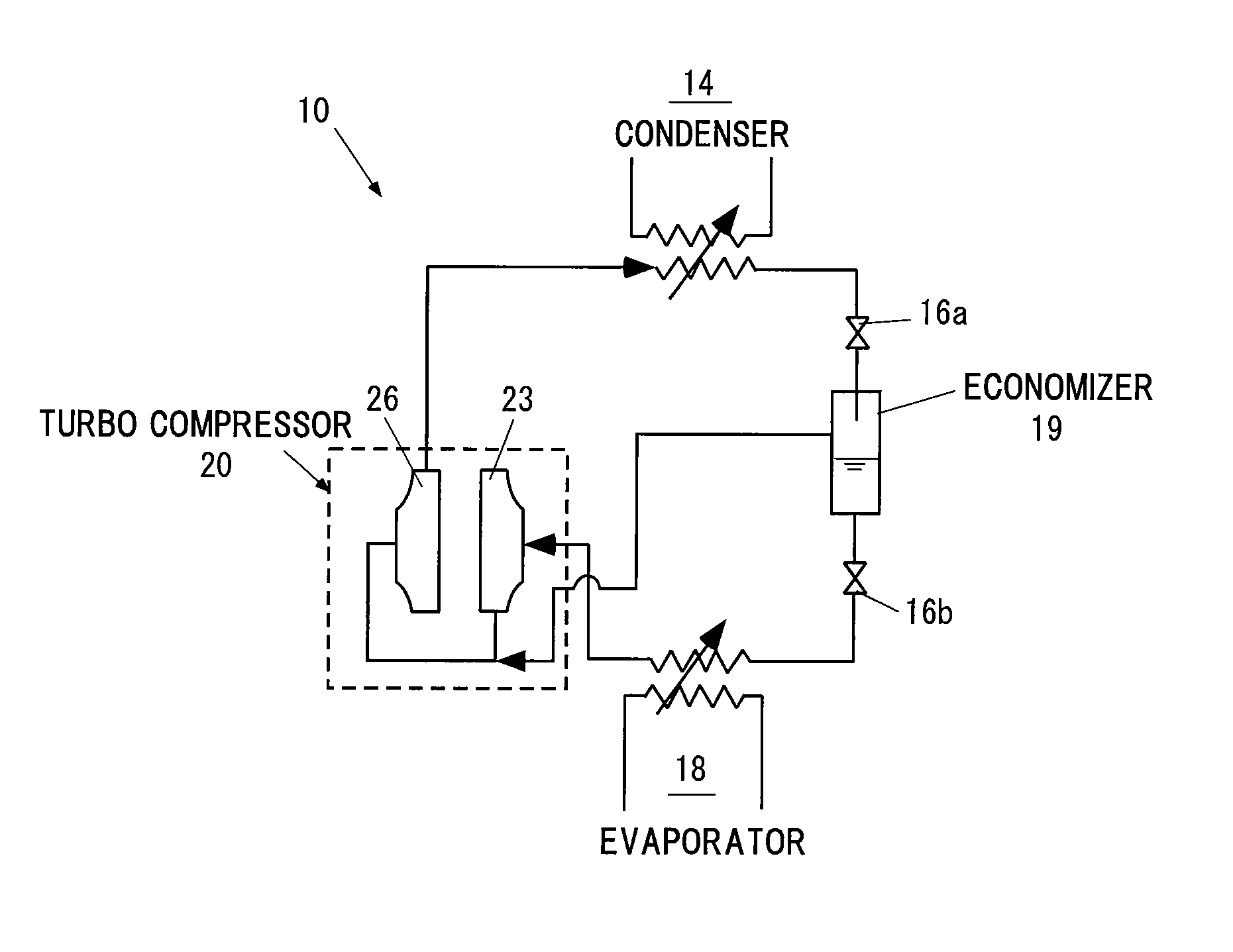

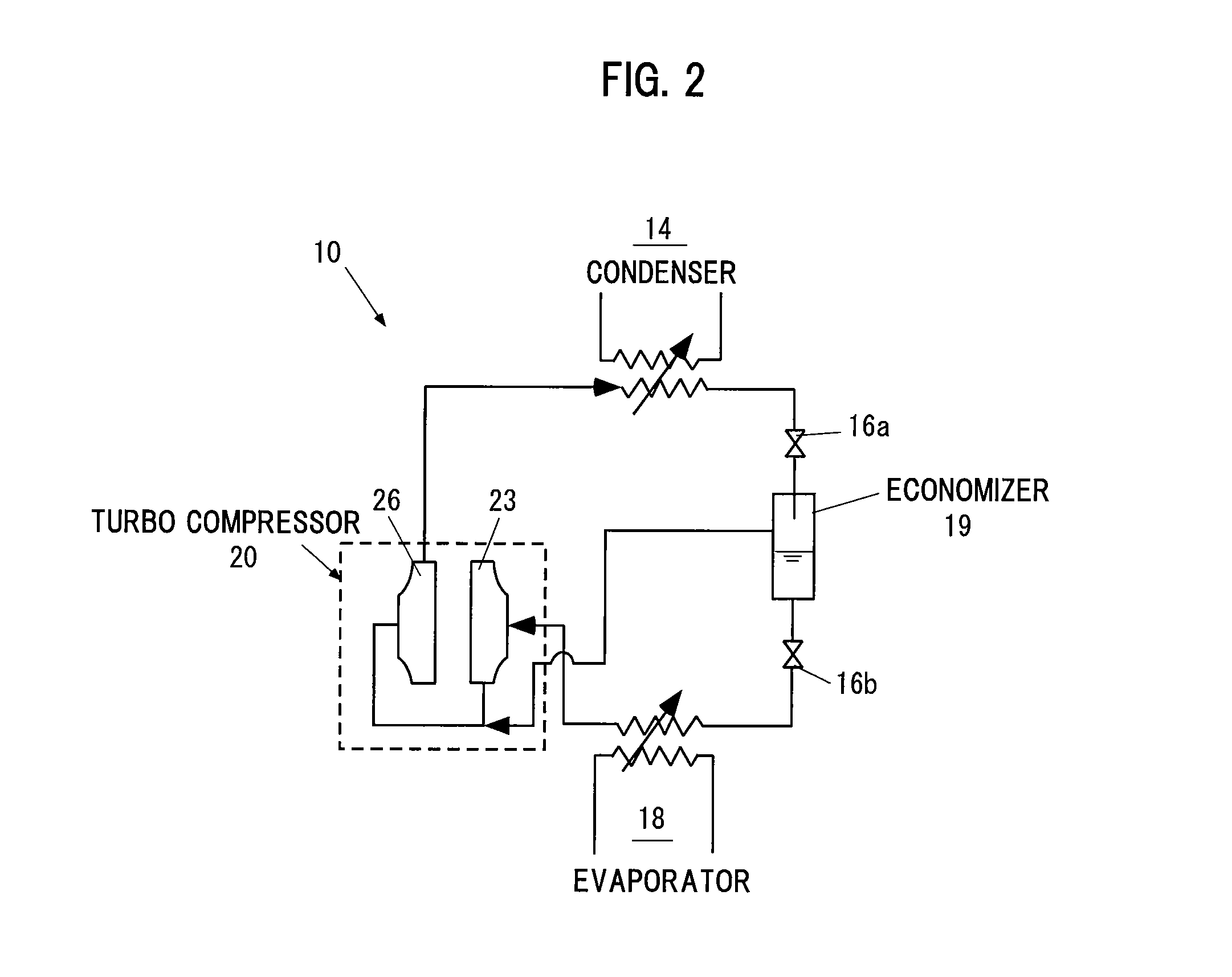

[0048]FIG. 2 is a view showing an arrangement of a refrigerating circuit of a turbo refrigerator 10 to which a turbo compressor in accordance with the present invention is applied.

[0049]In FIG. 2, the turbo refrigerator 10 is provided with a turbo compressor 20, a condenser 14, expansion valves 16a and 16b, an evaporator 18 and an economizer 19.

[0050]The turbo compressor 20 is a two-stage turbo compressor provided with a first stage centrifugal impeller 23 and a second stage centrifugal impeller 26, wherein the coolant gas is compressed by the first stage centrifugal impeller 23 on the upstream side, introduced into the second stage centrifugal impeller 26 and further compressed, and thereafter delivered to the condenser 14.

[0051]The condenser 14 cools and liquefies the compressed high-temperature and high-pressure coolant gas into a coolant liquid.

[0052]The expansion valves 16a and 1...

second embodiment

[0102]The description will be given below of a turbo compressor 20 in accordance with a second embodiment of the present invention.

[0103]FIG. 6 is a partly enlarged cross sectional view showing a structure of the turbo compressor 20 in accordance with the second embodiment.

[0104]As shown in FIG. 6, in accordance with the present embodiment, the bearings 50 are bearings commonly supporting the radial load and the thrust load applied to the rotating shaft 28, and comprise deep groove ball bearings 54 and 55 supporting the rotating shaft 28 at two axially spaced apart supporting positions, respectively. However, the deep groove ball bearing may be provided at any one of two supporting positions, and the other kind of bearing (for example, cylindrical roller bearing) may be provided at the other of the supporting positions, to support the rotating shaft 28.

[0105]In the bearings 50, the deep groove ball bearing 54 (hereinafter, refer to as “first deep groove ball bearing” as well) suppor...

third embodiment

[0112]The description will be given below of a turbo compressor in accordance with a third embodiment of the present invention. FIG. 7 is a partly enlarged cross sectional view showing a structure of the turbo compressor 20 in accordance with the third embodiment.

[0113]As shown in FIG. 7, in the present embodiment, the bearings 50 are constituted by the cylindrical roller bearings 51 and 52 supporting the radial load applied to the rotating shaft 28 at respective two axially spaced supporting positions, respectively, and the thrust bearing 53 supporting the thrust load applied to the rotating shaft 28.

[0114]With regard to axial positions of the rotating shaft 28, all of these bearings are arranged at the positions on the opposite side from the first stage centrifugal impeller 23 with respect to the second stage centrifugal impeller 26 in the axial direction (left positions from the second stage centrifugal impeller 26 in this drawing).

[0115]Further, as shown in FIG. 7, the speed inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com