Reagent refill and supply system for an SCR exhaust aftertreatment system

a technology of exhaust aftertreatment and supply system, which is applied in the direction of engines, mechanical equipment, machines/engines, etc., can solve the problems of logistics difficulties in supply solutions, and achieve the effect of quick and easy replenishmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

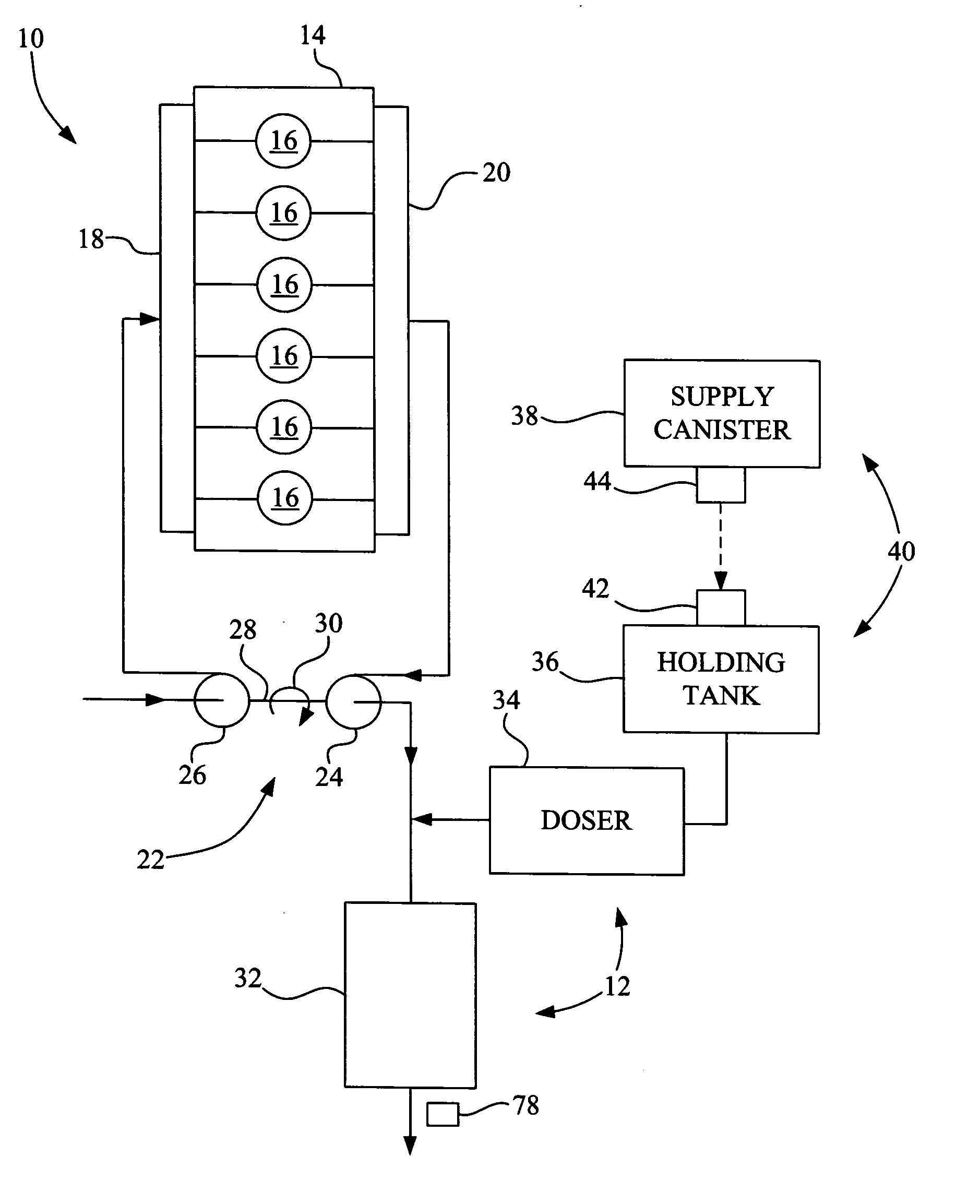

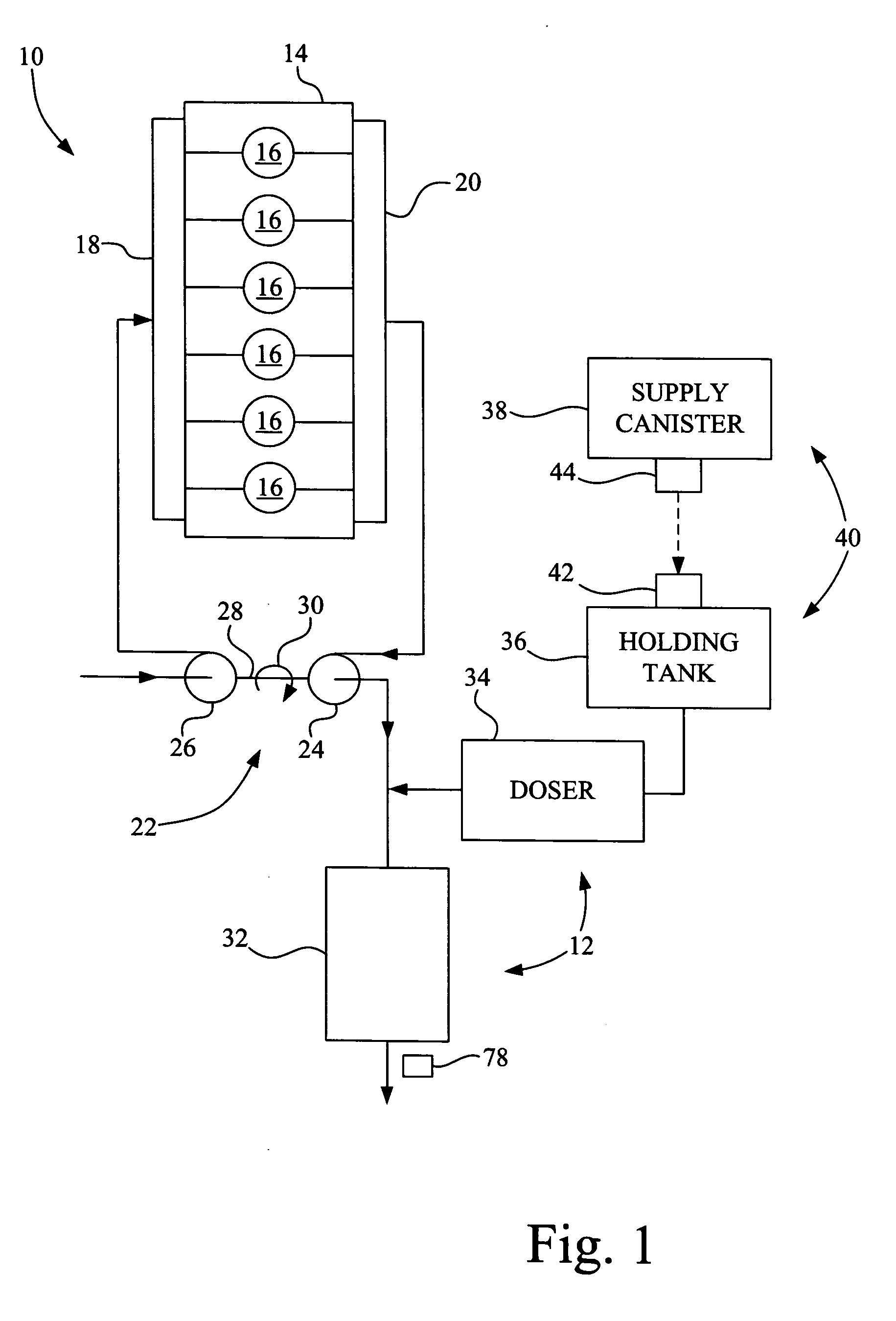

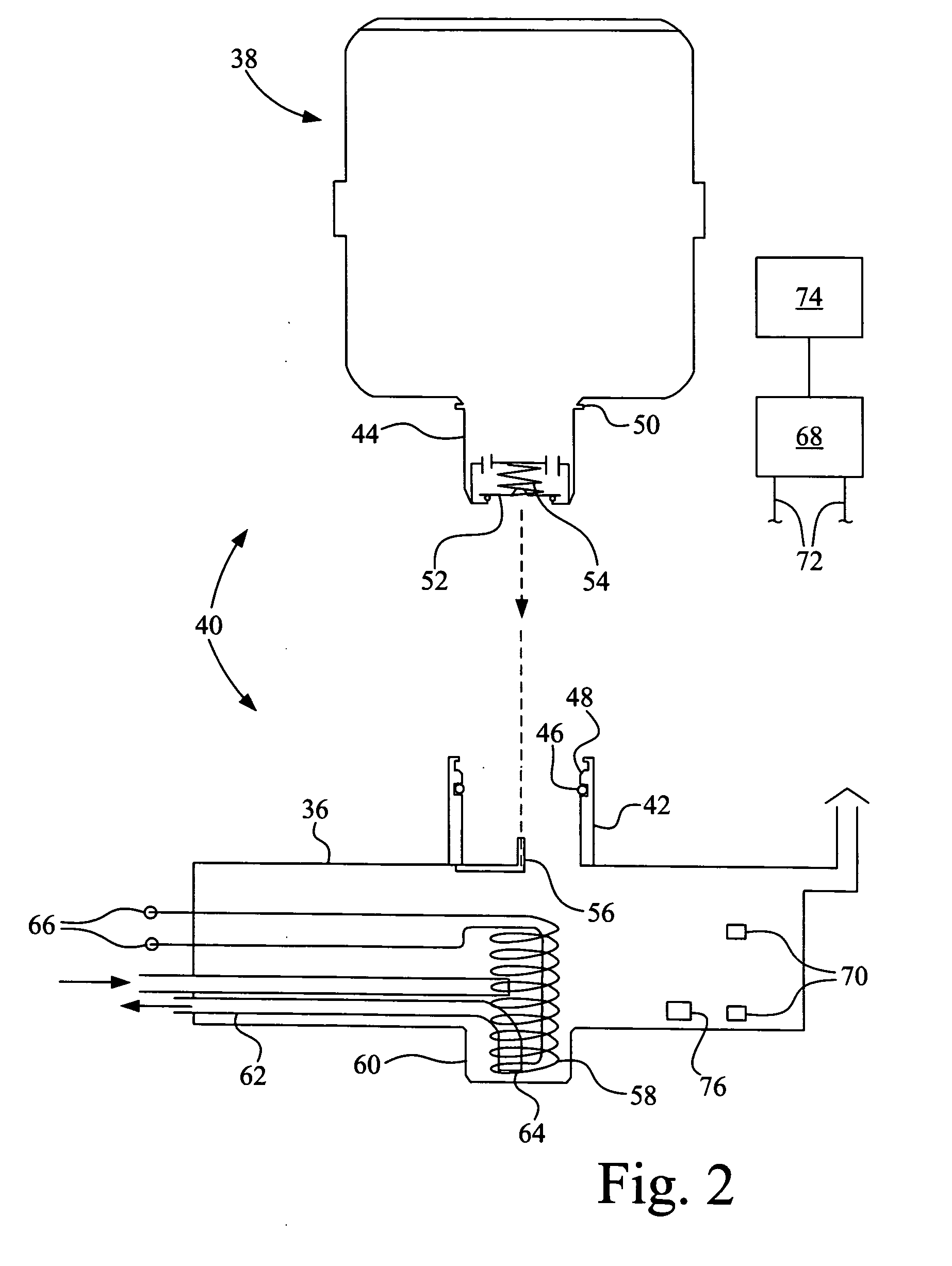

[0021] Referring now to the drawings, and more particularly to FIG. 1, there is shown an IC engine 10 including an embodiment of an SCR exhaust aftertreatment 12. In the embodiment shown, IC engine 10 is a diesel engine including a cylinder block 14 defining a plurality of combustion cylinders 16, an intake manifold 18, an exhaust manifold 20 and a turbocharger 22.

[0022] Cylinder block 14 is shown as including six combustion cylinders, but may also include a different number of combustion cylinders, such as eight, ten or twelve combustion cylinders.

[0023] Intake manifold 18 and exhaust manifold 20 are each in fluid communication with the plurality of combustion cylinders 16, and may be of single part design, as shown, or of multiple part design.

[0024] Exhaust manifold 20 discharges exhaust gas to turbine 24 of turbocharger 22. Turbine 24 may be of a fixed geometry as shown, or may be an adjustable turbine such as a variable geometry turbine (VGT). Exhaust gas from exhaust manifol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com