Methods and systems for controlling the temperature stability of an inductor

a technology of temperature stability and inductance, which is applied in the direction of pulse technique, measurement leads/probes, instruments, etc., can solve the problems source of temperature drift error, and relatively harsh environment in which the proximity probe operates, and achieves substantial constant resistance versus temperature profile of the coil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

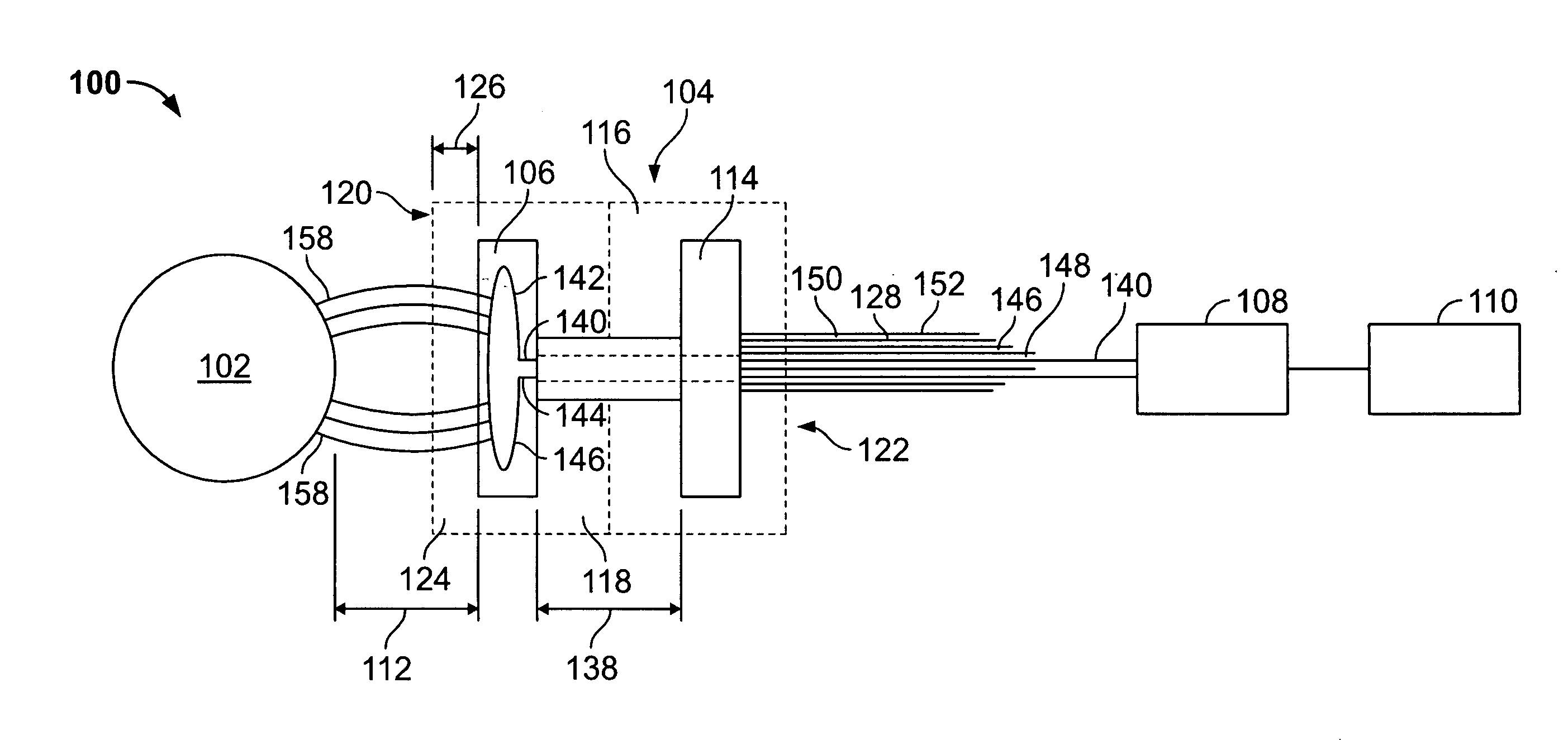

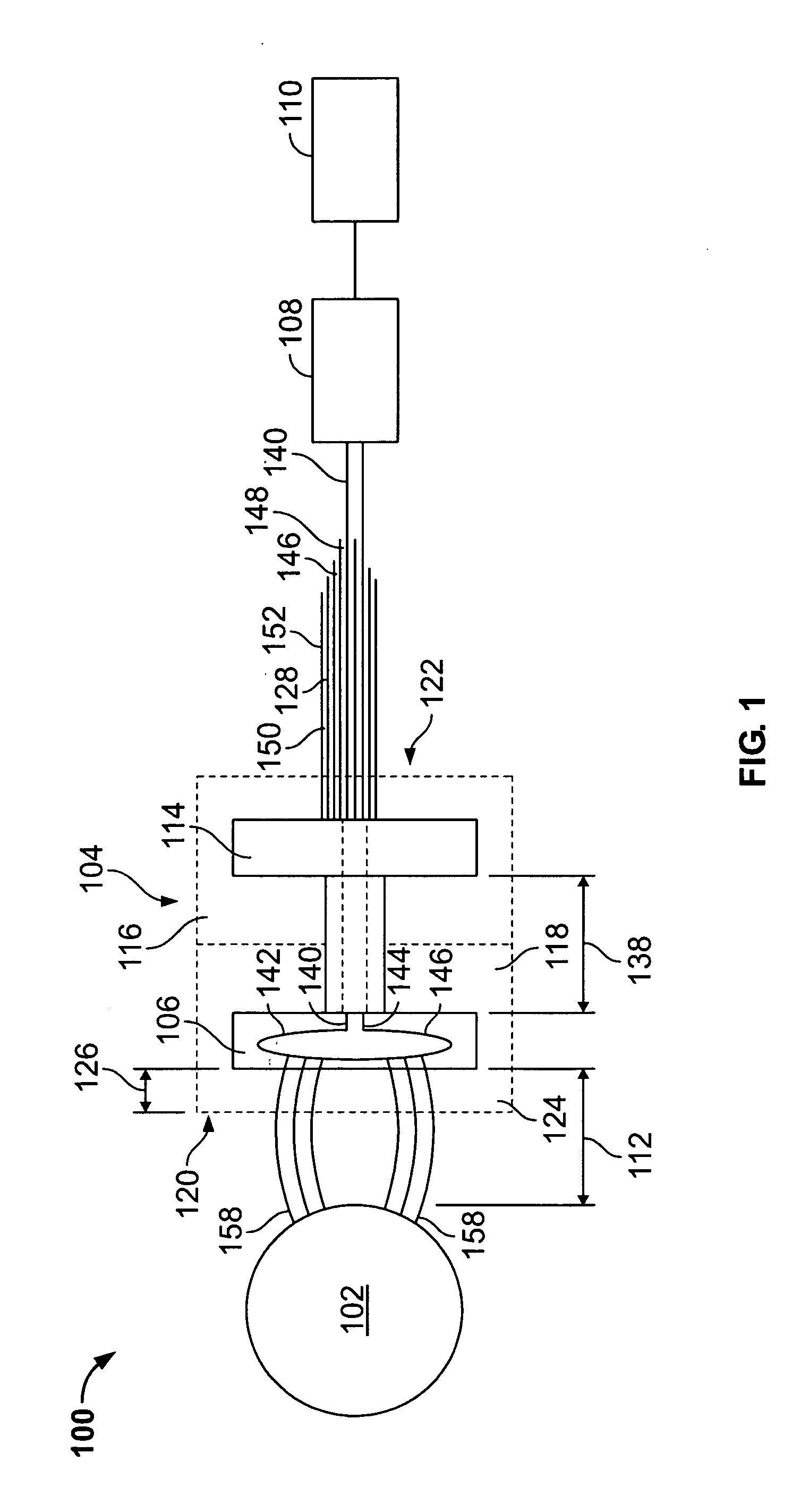

[0013]FIG. 1 is a schematic view of a proximity probe system 100. Proximity probe system 100 is configured to monitor a target object, for example, a rotating shaft 102 of a machine (not shown). Proximity probe system 100 includes a proximity probe 104 including a temperature stable inductor 106, an electronic circuit 108 and a monitoring system 110. Typically, proximity probe 104 is operatively coupled to electronic circuit 108 and is positioned adjacent rotating shaft 102 for monitoring the vibrational or rotor position characteristics thereof. Proximity probe 104 uses eddy currents to generate a signal indicative of a gap 112 between rotating shaft 102 and inductor 106. Proximity probe 104 includes a tuning disk 114 magnetically coupled to inductor 106 for setting a scale range for the output of proximity probe 104.

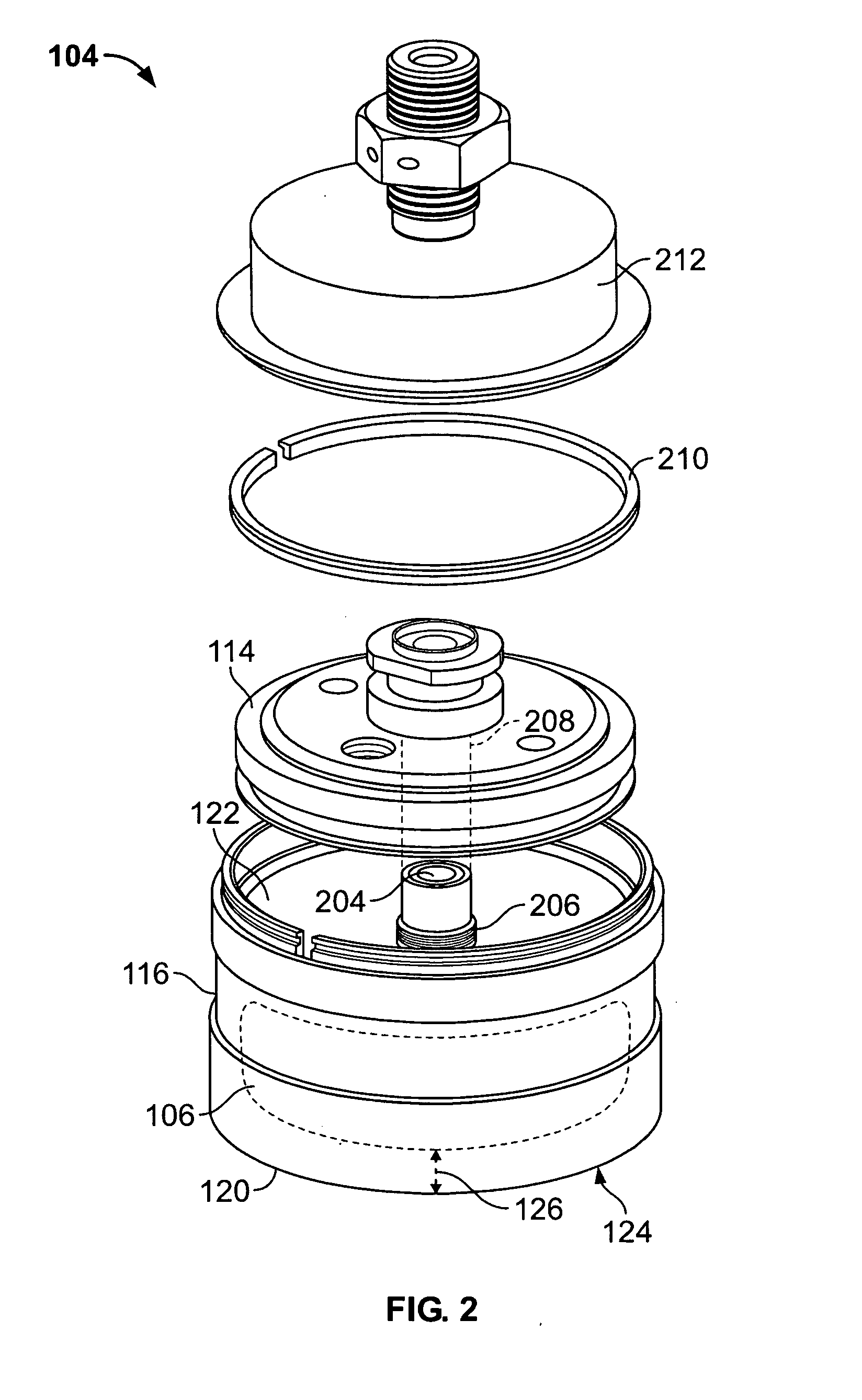

[0014] Proximity probe 104 defines a common enclosure 116 housing both inductor 106 and tuning disk 114. In the exemplary embodiment, proximity probe 104 is formed fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com