Method of forming bent heat dissipating unit and apparatus therefor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

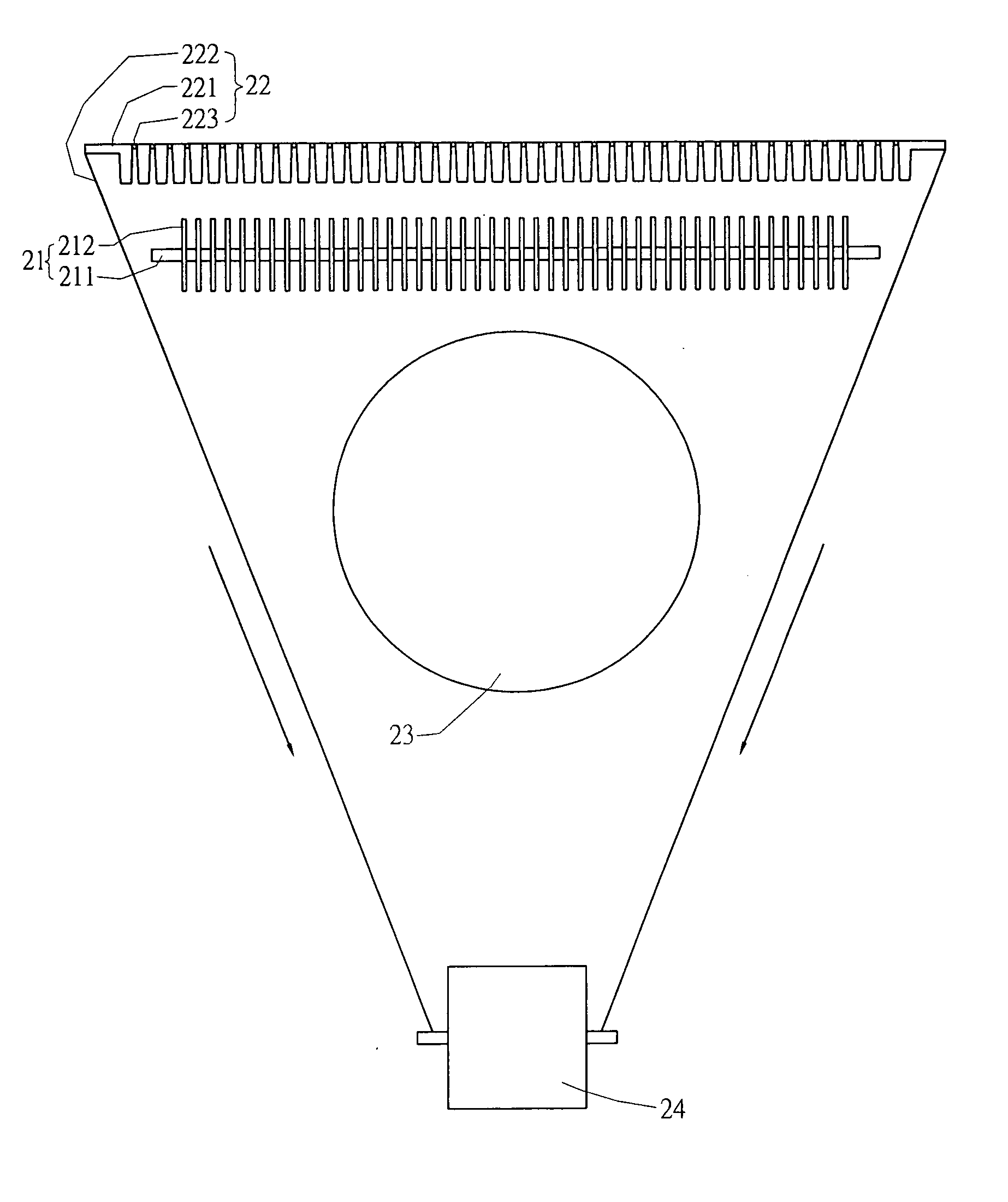

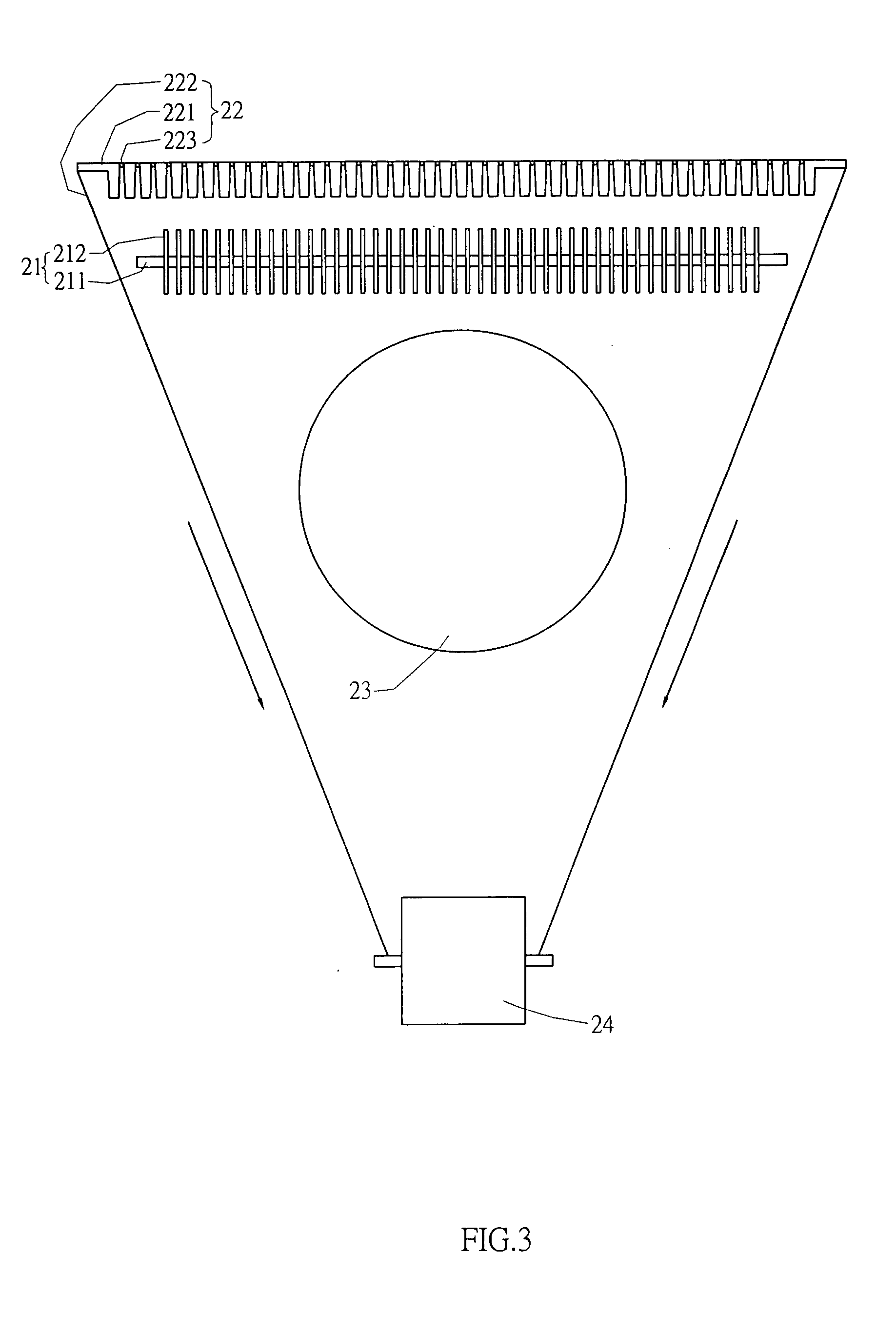

[0019] Please refer to FIGS. 3 and 4 that show the bending of a heat dissipating unit using a method and apparatus according to a preferred embodiment of the present invention. As shown, the apparatus for bending a heat dissipating unit 21 according to the preferred embodiment of the present invention includes a forming die assembly 22, a forming block 23, and a processing machine 24.

[0020] The heat dissipating unit 21 includes a heat pipe 211, which is originally a straight pipe, and a plurality of radiating fins 212 sequentially put on and around the straight heat pipe 211.

[0021] The forming die assembly 22 includes a plurality of locating die units 221 and a carrier 222. The locating die units 221 are sequentially connected to one another using the carrier 222, so that the locating die units 221 are arranged side by side on the carrier 222. It is noted any two adjacent locating die units 221 on the carrier 222 are pivotally connected at an end to each other via a pivot 223, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com