Modular heat distribution unit for hydronic heating systems

a technology of hydronic heating and modules, applied in the direction of fluid heaters, heating types, lighting and heating apparatus, etc., can solve the problems of complex structure, high construction cost, time-consuming, etc., and the heat distribution center is the most complicated, expensive and time-consuming component to construct, and the structure is rarely organized as well. , the problem of complex structur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

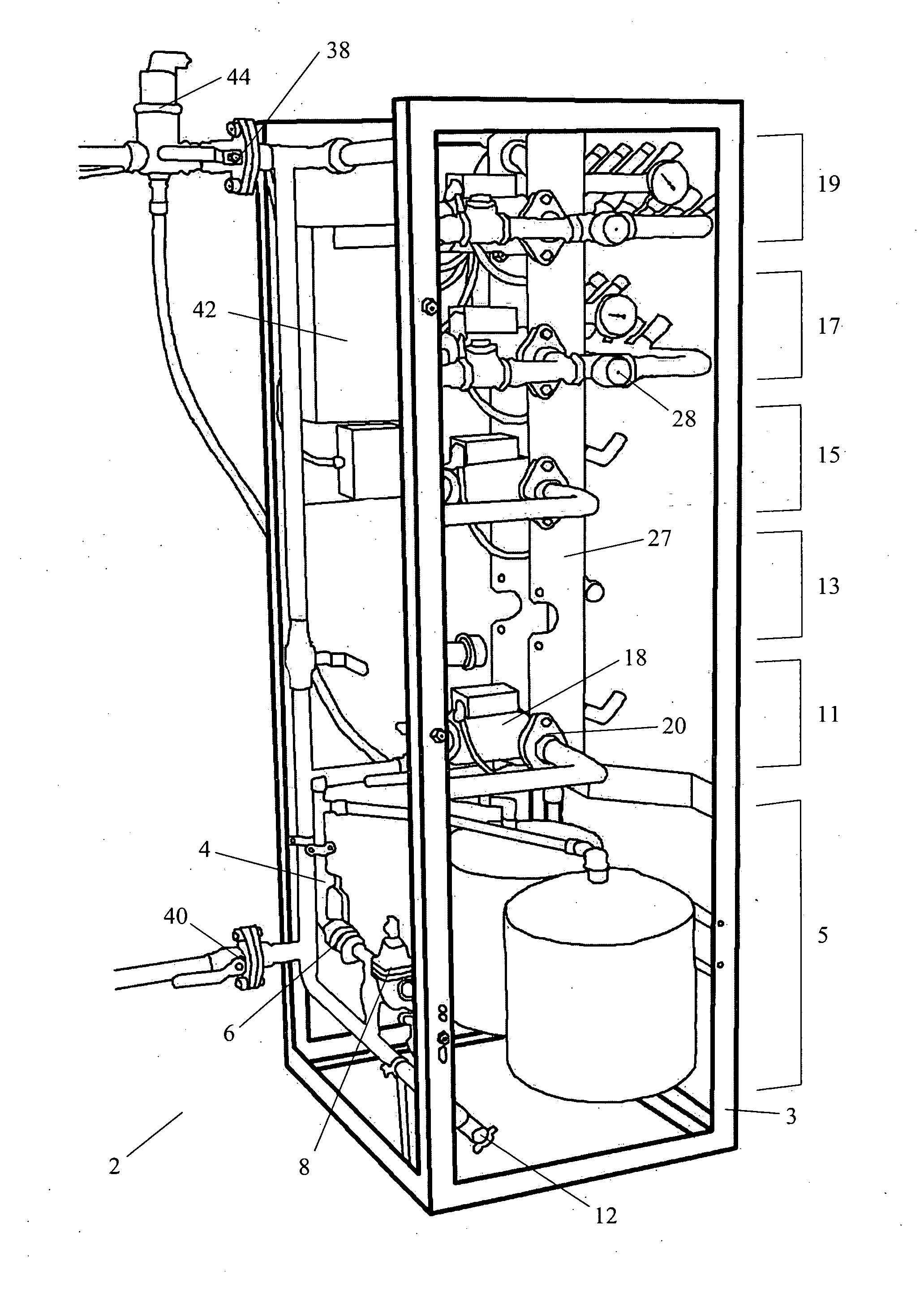

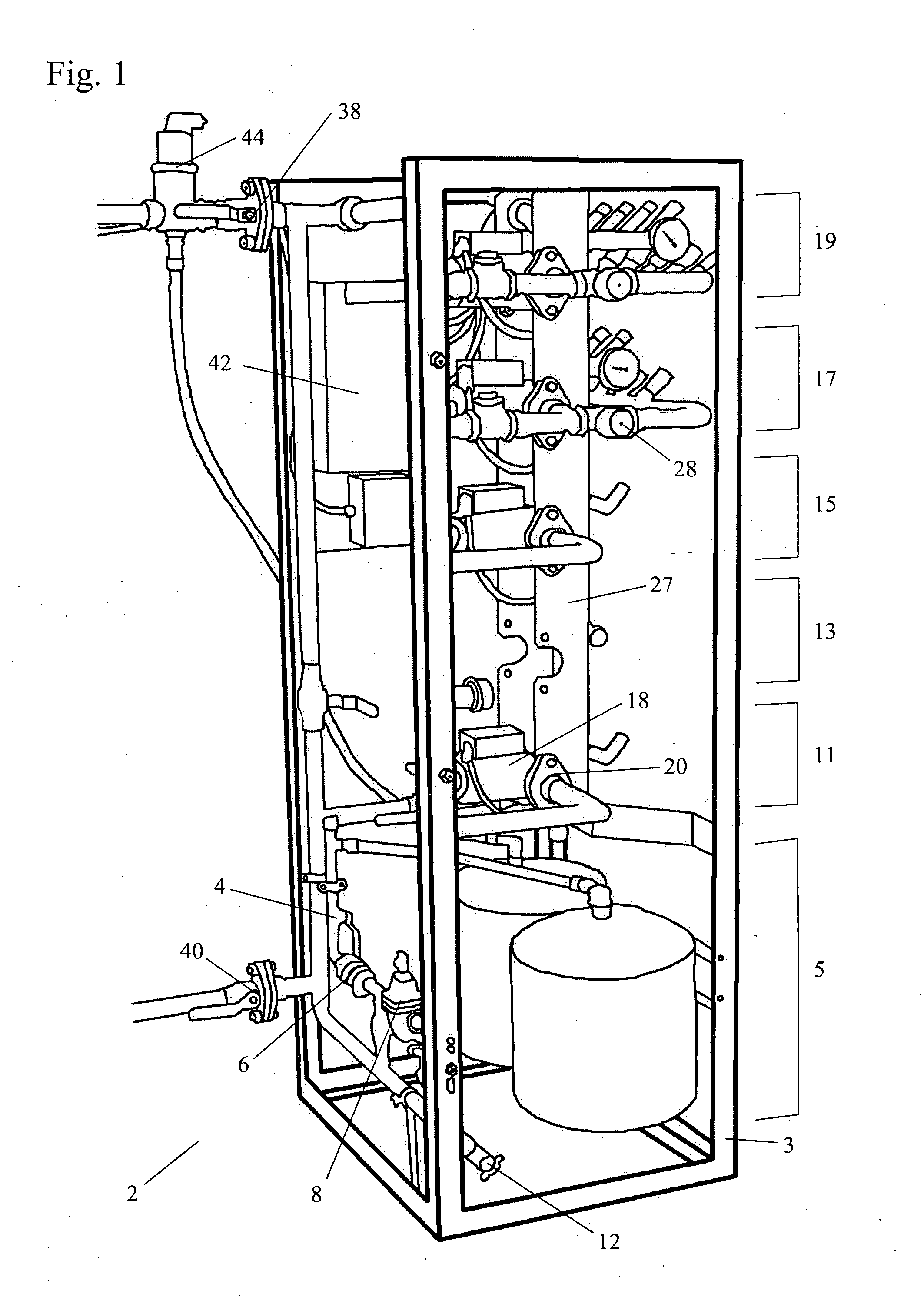

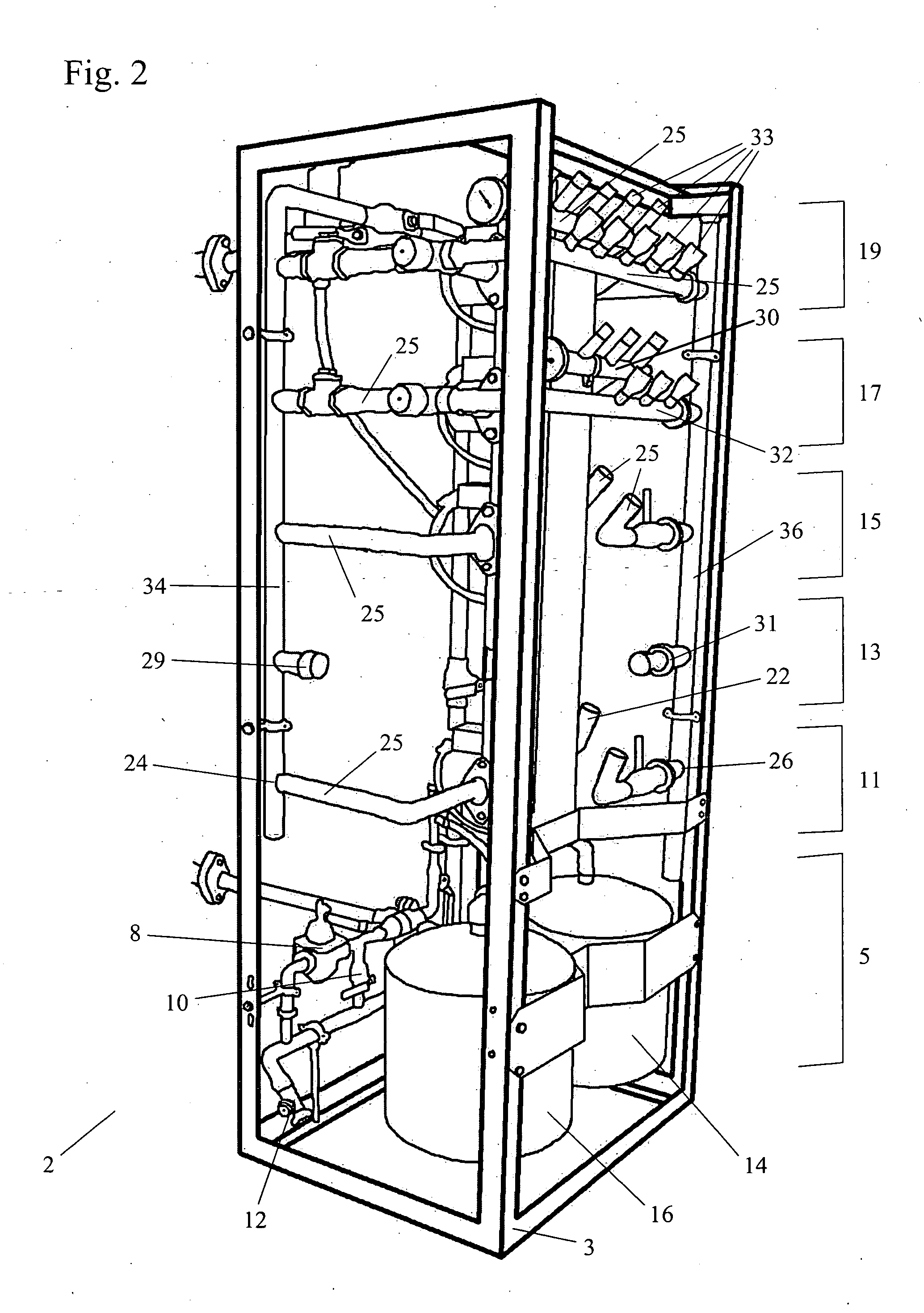

[0022] A modular heat distribution unit of the present invention is preferably an off-site-constructed unit requiring only on-site attachment to the hot water source, to the heating assemblies of the building, to the thermostat wiring, and to a power supply. Heating assemblies may include hot water domestic storage tanks. As such, a modular heat distribution unit of the present invention is easily connected to the other components of the heating system in a matter of several hours. The modular heat distribution unit preferably includes a make-up water sub-module and a plurality of heating zone distribution sub-modules. Each heating zone distribution sub-module is preferably one of either a sub-module for a radiant floor heating zone, a sub-module for a baseboard heating zone, a sub-module for a domestic hot water zone, or a spare zone that may be used at a later time. In other embodiments, heating zone distribution sub-modules serve swimming pool heating systems or ice melting syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com