Trailer hitch

a trailer and hitch technology, applied in the field of trailer hitch assembly, can solve the problems of requiring skill and/or multiple attempts to properly align, damage to the vehicle and trailer, and difficulty in adjusting the traverse of the trailer, so as to reduce the friction coefficient and the effect of lowering the friction coefficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

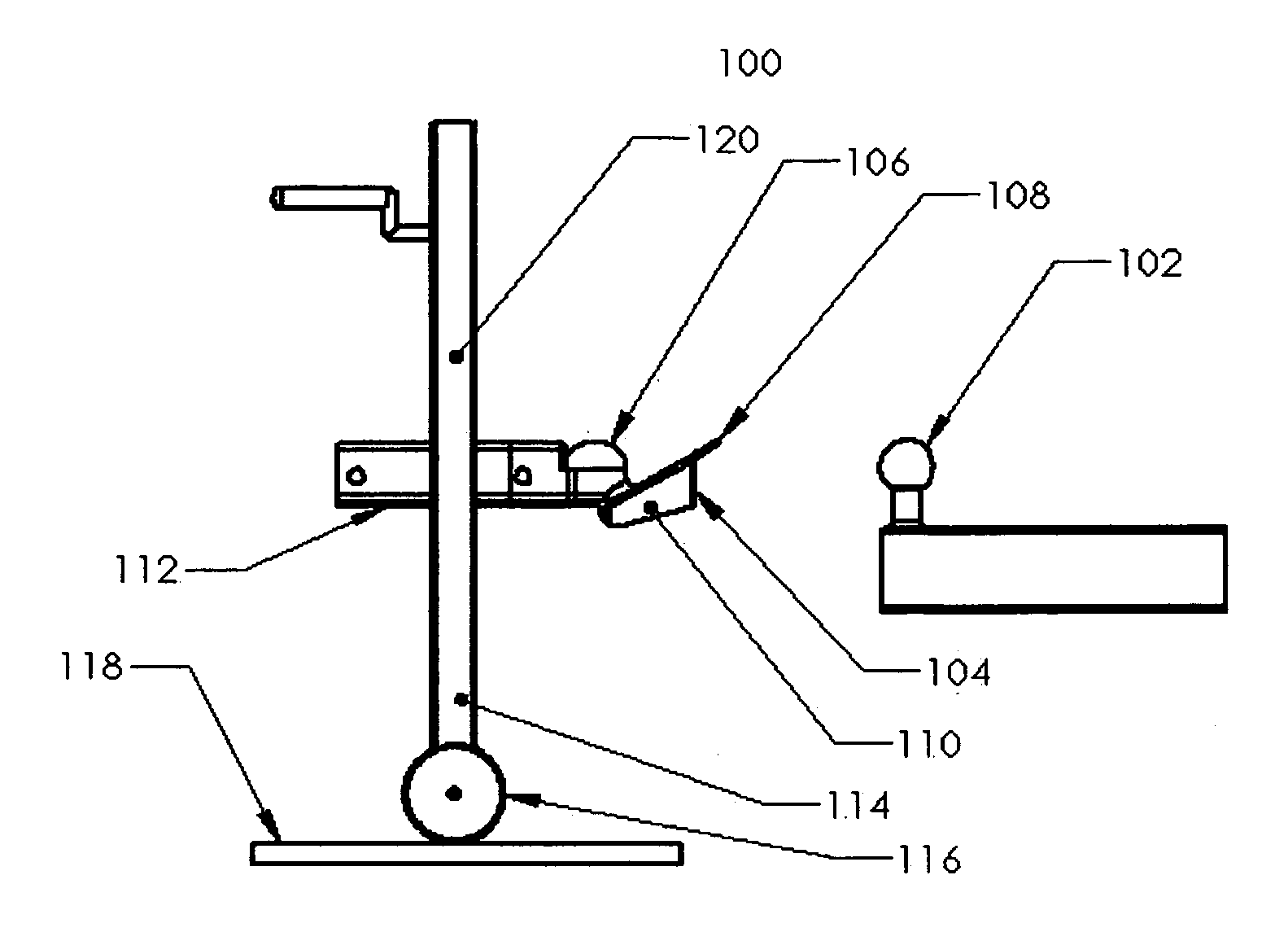

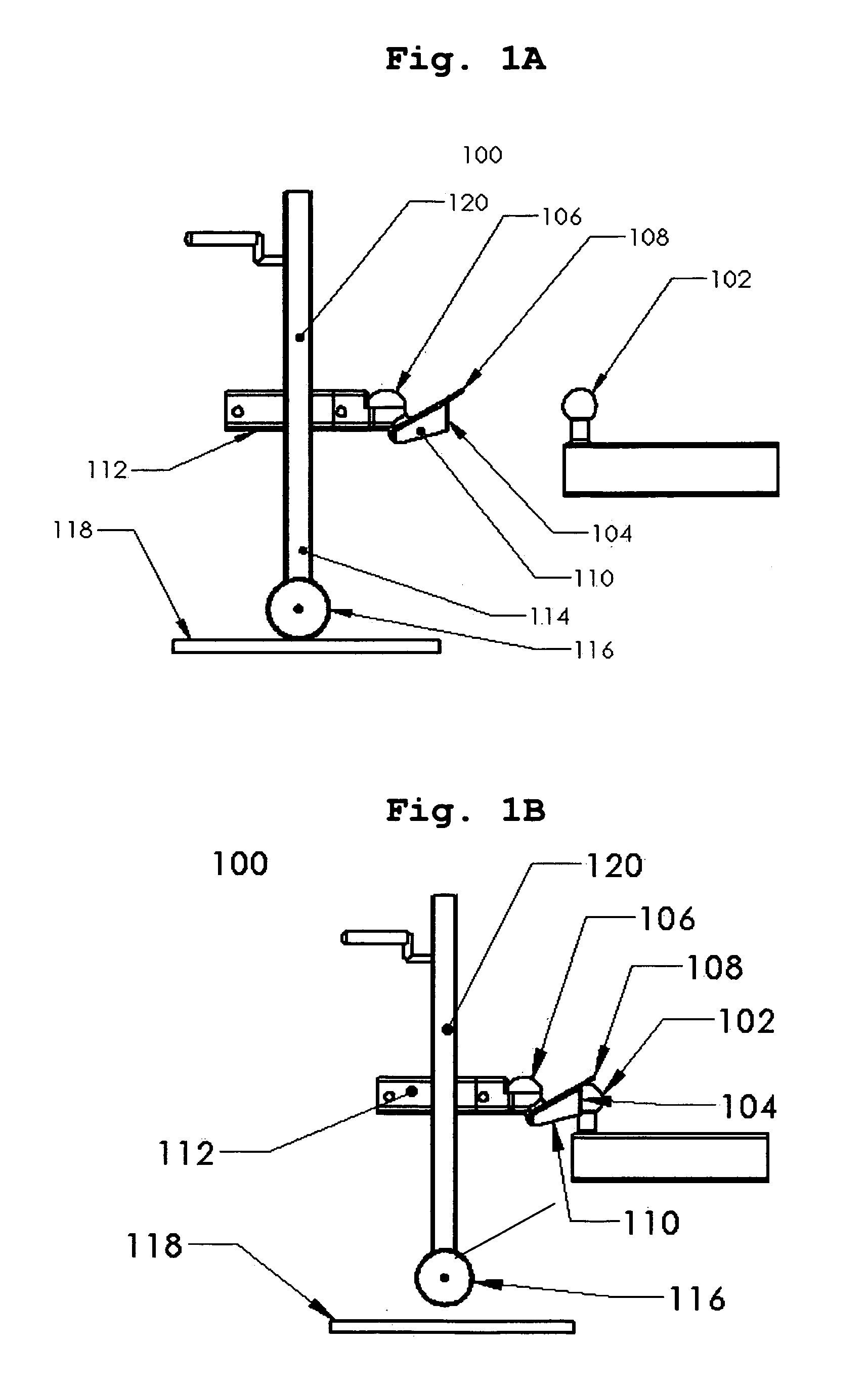

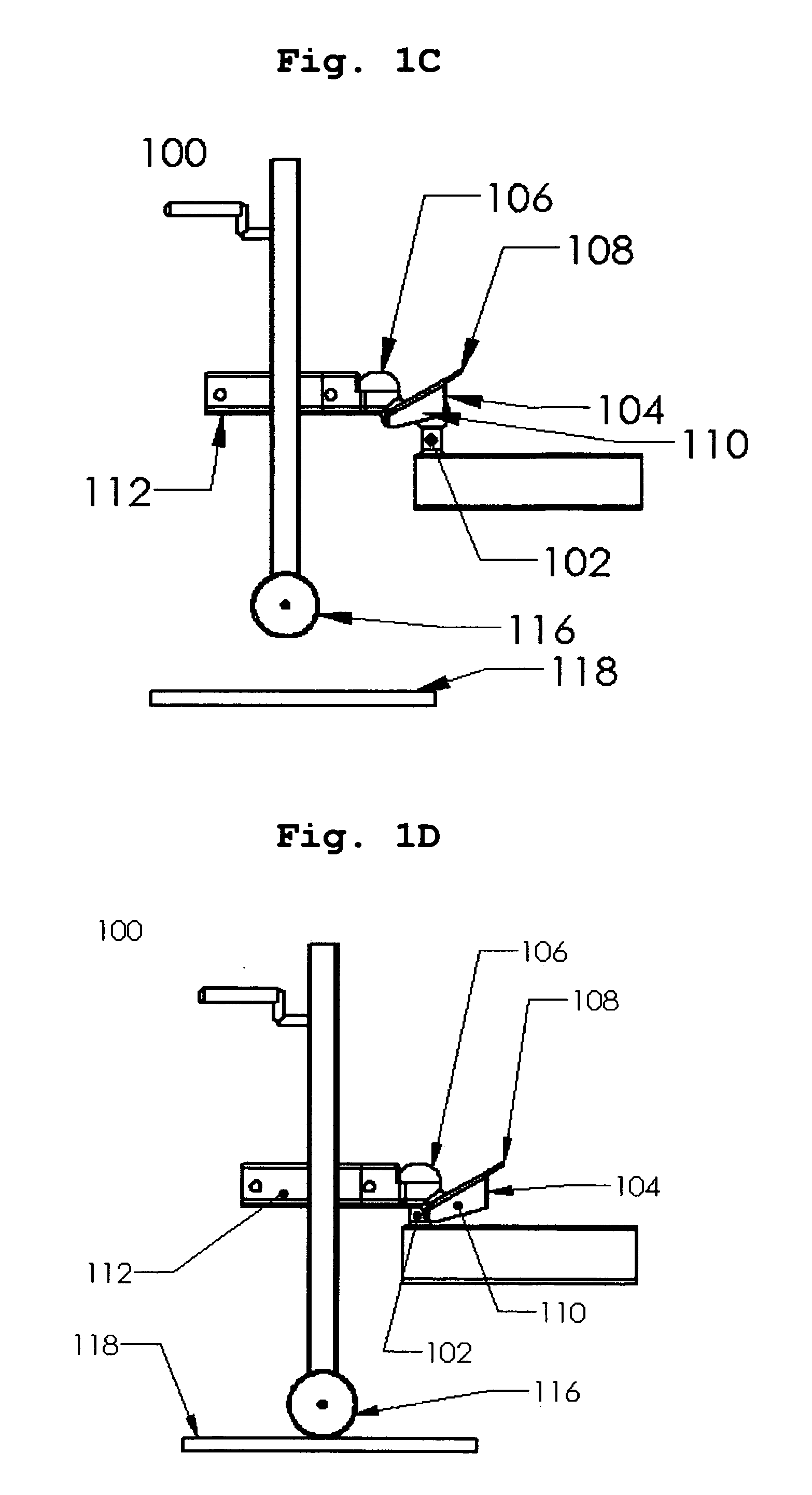

Image

Examples

first embodiment

[0038] The “U” shaped channels 304 may also be coupled to the frame or socket portion with fasteners 310. The fasteners 310 may include, for example, but not limited to bolts, screws, rivets, welds, or adhesives. The fasteners 310 may permanently couple the guide assembly 300 to the trailer or, for example, may utilize bolts with wing nuts to allow the user the ability to remove the guide assembly 300 as needed. Referring to FIG. 3A and 3B, the receiver portion 308 may have a lip portion 314. The lip portion 314 may be located between the receiving plate 308 and the opening of the socket. The lip portion 314 provides a recess for the front flange of the trailer hitch assembly in the The side plates 312 may extend down and run parallel with the receiver plate 308 to prevent any interference during towing as shown in FIG. 3B. This allows the side plates 312 to ride above the towing portion as shown in FIG. 3E. The side plates 312 may also extend downward and specifically be designed ...

third embodiment

[0043] According to this invention, the lip portion 314, referring to FIGS. 3A-D, may provide a pocket for the front flange of the hitch socket. This pocket feature may be on the ball contact surface of the receiver plate 308 as in FIG. 3D or may be a feature cut into the wear plate 908 as in FIG. 6B. The pocket allows an area for the hitch flange 910 to slip into for a smooth transition of the ball into the socket without hitting or catching on the bump that would be otherwise be encountered by the leading edge of the socket flange 910. This feature may prevent excessive resistance to the coupling process or wear or damage to the hitch flange. Referring to FIG. 6B, this pocket feature 906 may also be formed or cut into the wear plate 908 to create a smooth transition as the hitch ball travels towards and into the hitch socket 608 without hitting or catching on a bump that would otherwise be created by the leading edge of the hitch flange 910.

[0044] According to FIG. 6A, FIG. 6B, FI...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com