Vacuum cleaner with improved hygenic performance

a vacuum cleaner and hygenic technology, applied in the field of vacuum cleaners, can solve the problems of contaminating the home environment, affecting the health of the environment, spreading unpleasant odors and unhealthy bacteria,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

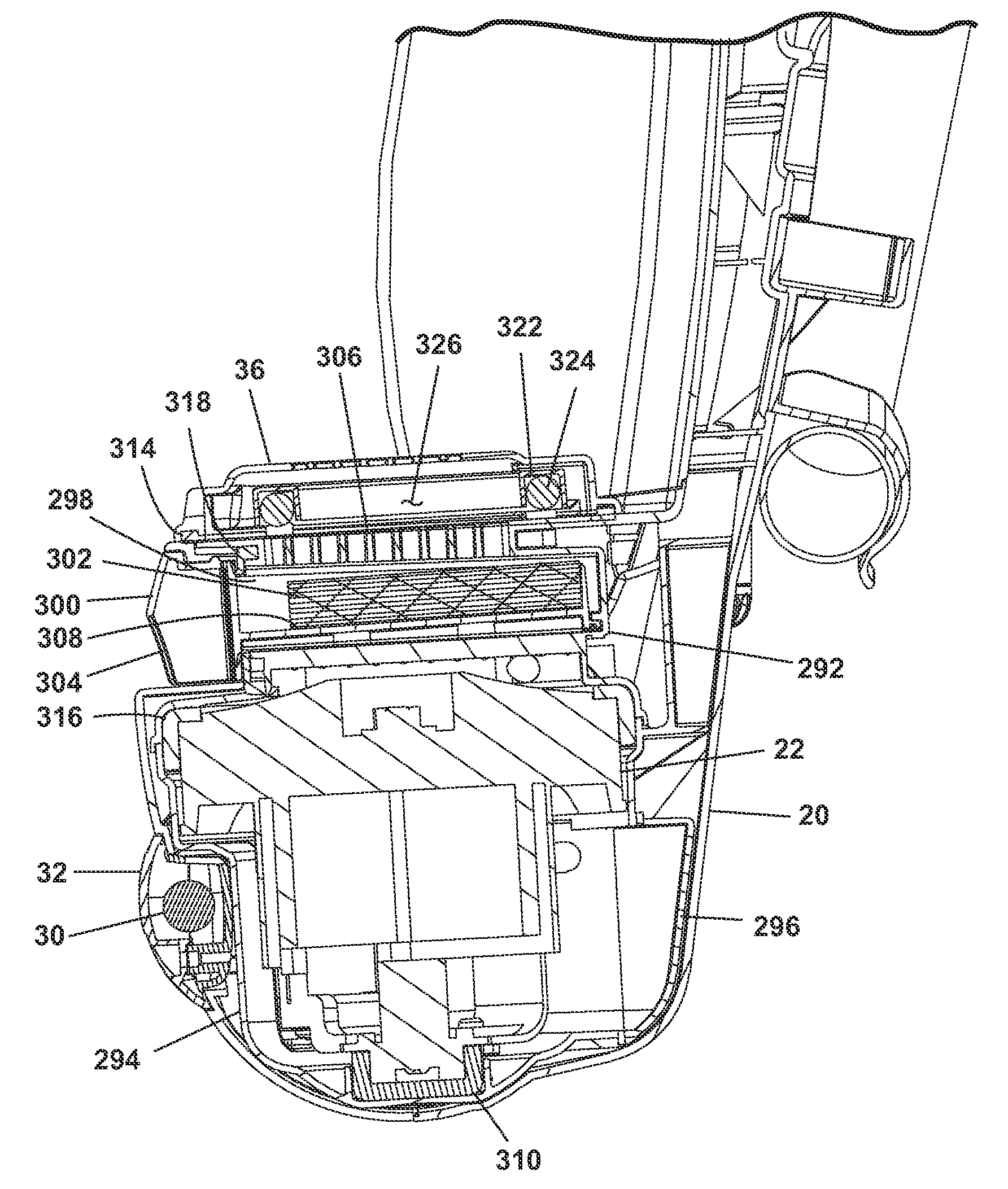

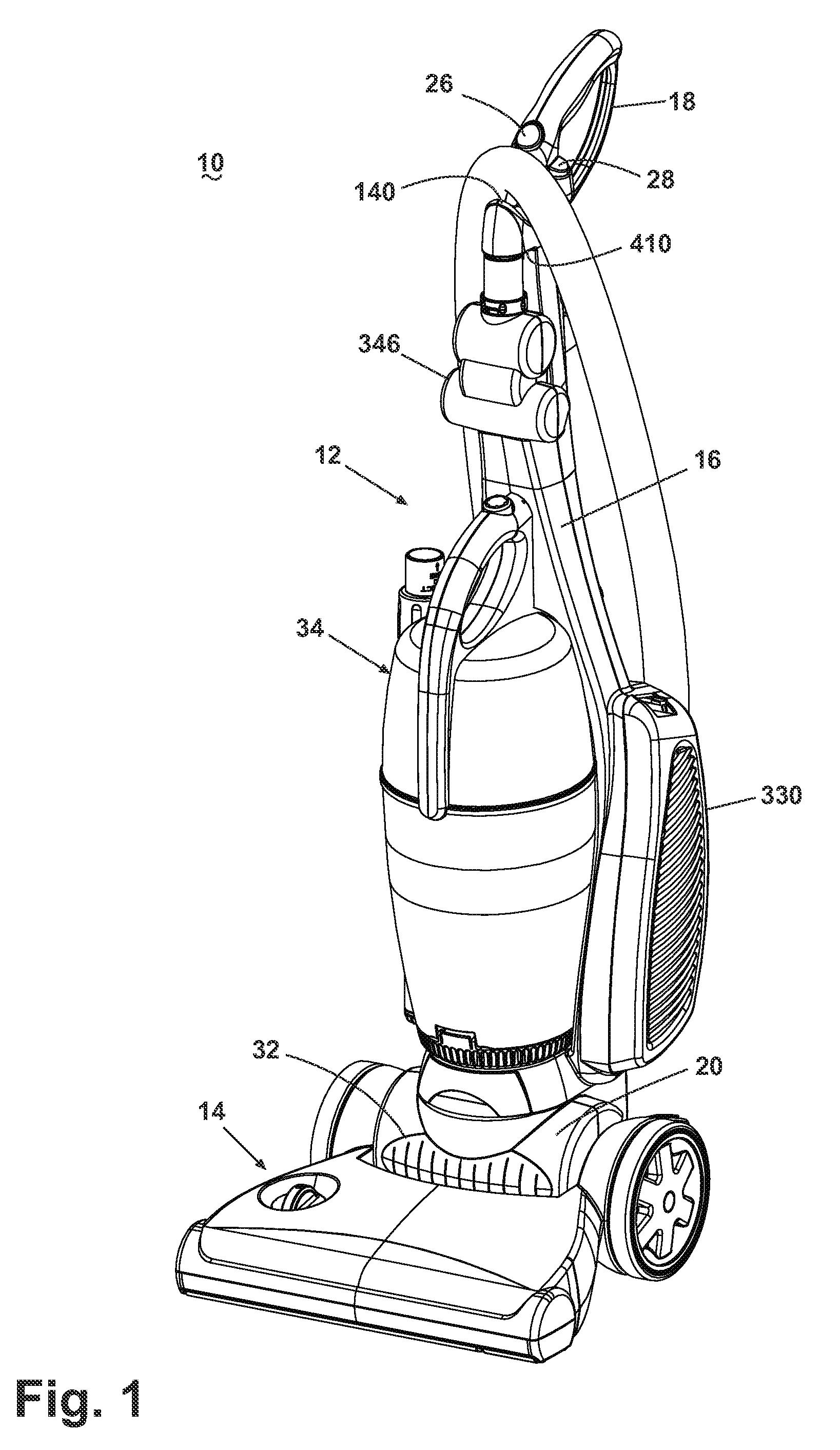

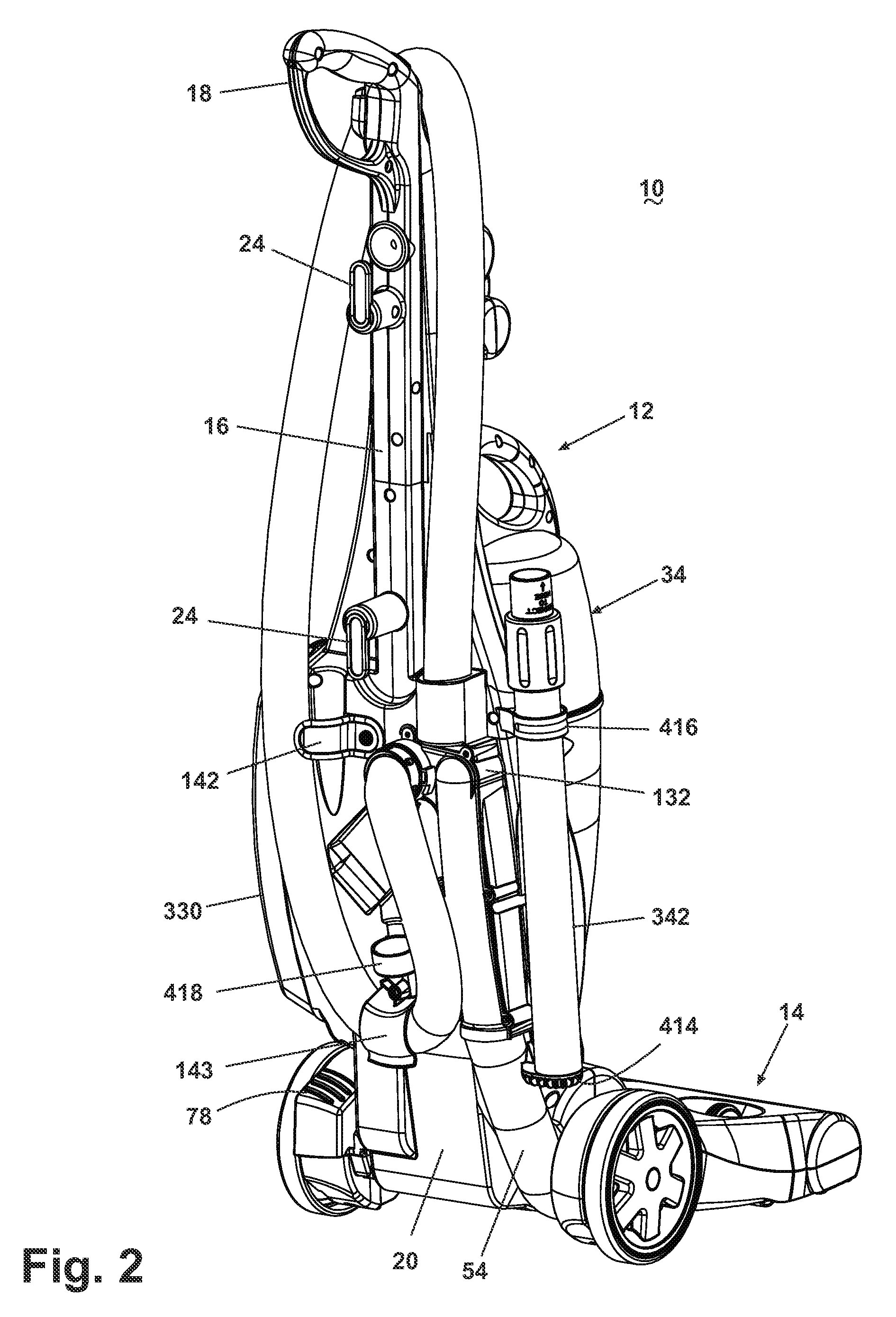

[0056]Referring to the drawings, and in particular to FIGS. 1-2, an upright vacuum cleaner 10 according to the present invention comprises an handle assembly 12 pivotally mounted to a cleaning head or foot assembly 14. The handle assembly 12 further comprises a primary support section 16 with a closed-loop handgrip 18 on one end to facilitate movement by a user. The handgrip 18 is preferably overmolded with a soft low durometer material for providing a comfortable grip for the user. A motor cavity 20 is formed at an opposite end of the handle assembly 12 and houses a source of suction, illustrated herein as a vertically-oriented motor / fan assembly 22 (FIG. 27). The handle assembly 12 pivots relative to the foot assembly 14 through an axis of rotation formed perpendicular to a shaft within the motor / fan assembly 22. An electric cord (not shown) extending from the motor / fan assembly 22 is stored on a pair of opposed cord wraps 24 provided on the rear of the primary support section 16....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com