Drum type washing machine and drying method thereof

a washing machine and drum technology, applied in the field of drum type washing machines, can solve the problems of long drying time of laundry, damaged laundry, incomplete drying of laundry, etc., and achieve the effect of reducing the drying time of laundry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

1. Embodiment 1

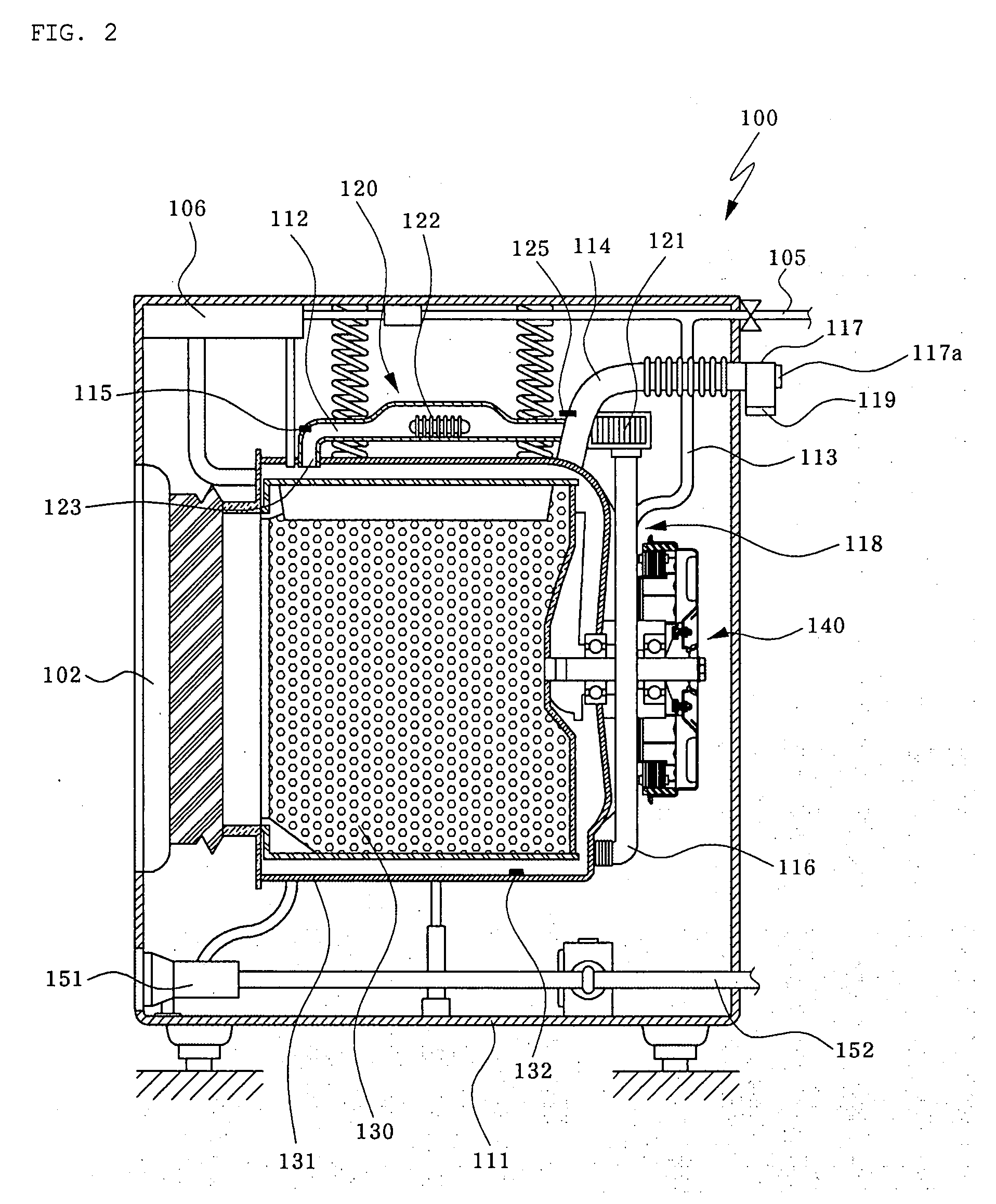

[0085]FIG. 4 is a flowchart illustrating the drying cycle of the drum type washing machine according to the first preferred embodiment of the present invention, and FIGS. 5 and 6 are flowcharts illustrating respective drying cycles in FIG. 4.

[0086]The drying method of a drum type washing machine according to the first preferred embodiment of the present invention is a method in which heat is not applied to the laundry when the drum motor 140 is driven with the first motor driving range, but in which heat is applied when the drum motor 140 is driven within a second motor driving range after that. As shown in FIG. 4, the user firstly selects the drying mode through the key input section 170 (S710), and selects the completely drying mode of the drying modes, and then an eccentricity is measured (S720).

[0087]There are several methods of measuring the eccentricity, one of estimating duty of a pulse width modulation (PWM) control signal, and the other one of measuring time ...

embodiment 2

2. Embodiment 2

[0107]FIG. 7 is a flowchart illustrating a drying cycle of a drum type washing machine according to a second preferred embodiment of the present invention, FIGS. 8, 9, and 10 are flowcharts illustrating respective drying cycles in FIG. 7, FIG. 11 is a graph illustrating the relation between temperature and time during the drying cycle of the drum type washing machine according to the second preferred embodiment of the present invention, and FIG. 12 is a graph illustrating the relation between temperature and time with respect to the quantity of laundry during the drying cycle of the drum type washing machine according to the second preferred embodiment of the present invention.

[0108]The drying method of a drum type washing machine according to the second preferred embodiment of the present invention includes the steps of selecting the drying mode through the key input section 170 by the user (S110), and measuring the eccentricity when the user selects the completely d...

embodiment 3

3. Embodiment 3

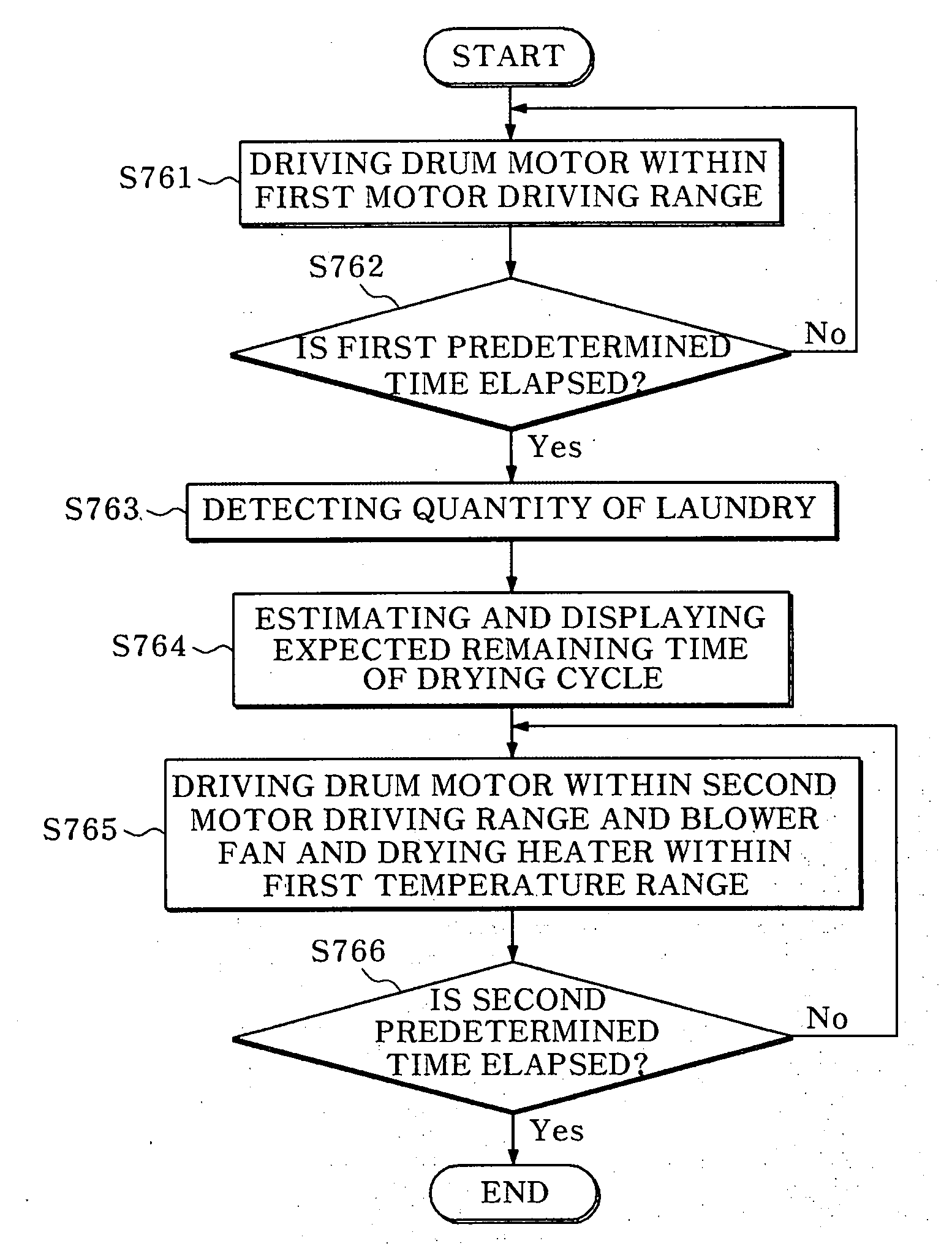

[0148]Next, a drying method according to a third preferred embodiment of the present invention will be described with reference to FIG. 13.

[0149]FIG. 13 is a flowchart illustrating a drying cycle of a drum type washing machine according to the third preferred embodiment of the present invention.

[0150]The drying method of a drum type washing machine according to the third preferred embodiment of the present invention is similar as that according to the second preferred embodiment of the present invention. However, the drying method according to the third preferred embodiment of the present invention relates a drying method in a case of selecting the time drying mode different from the case of selecting the completely drying mode when the user selects the drying mode in the first preferred embodiment of the present invention.

[0151]Thus, it will be described in brief with respect to the same as that in the second preferred embodiment of the present invention, and other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com