Kitchen Ventilation System With Fan Having Positive Pressure-To-Output Characteristic Applied Thereto

a technology of positive pressure and ventilation system, applied in the field of kitchen ventilation system, can solve the problems of unnecessarily large power output, insufficient discharge of polluted materials by hood 20 installed on the lower floors, and insufficient installation on the higher floors, so as to achieve the effect of reducing noise, reducing installation costs and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, a preferred embodiment of the present invention will be described in detail with reference to the accompanying drawings.

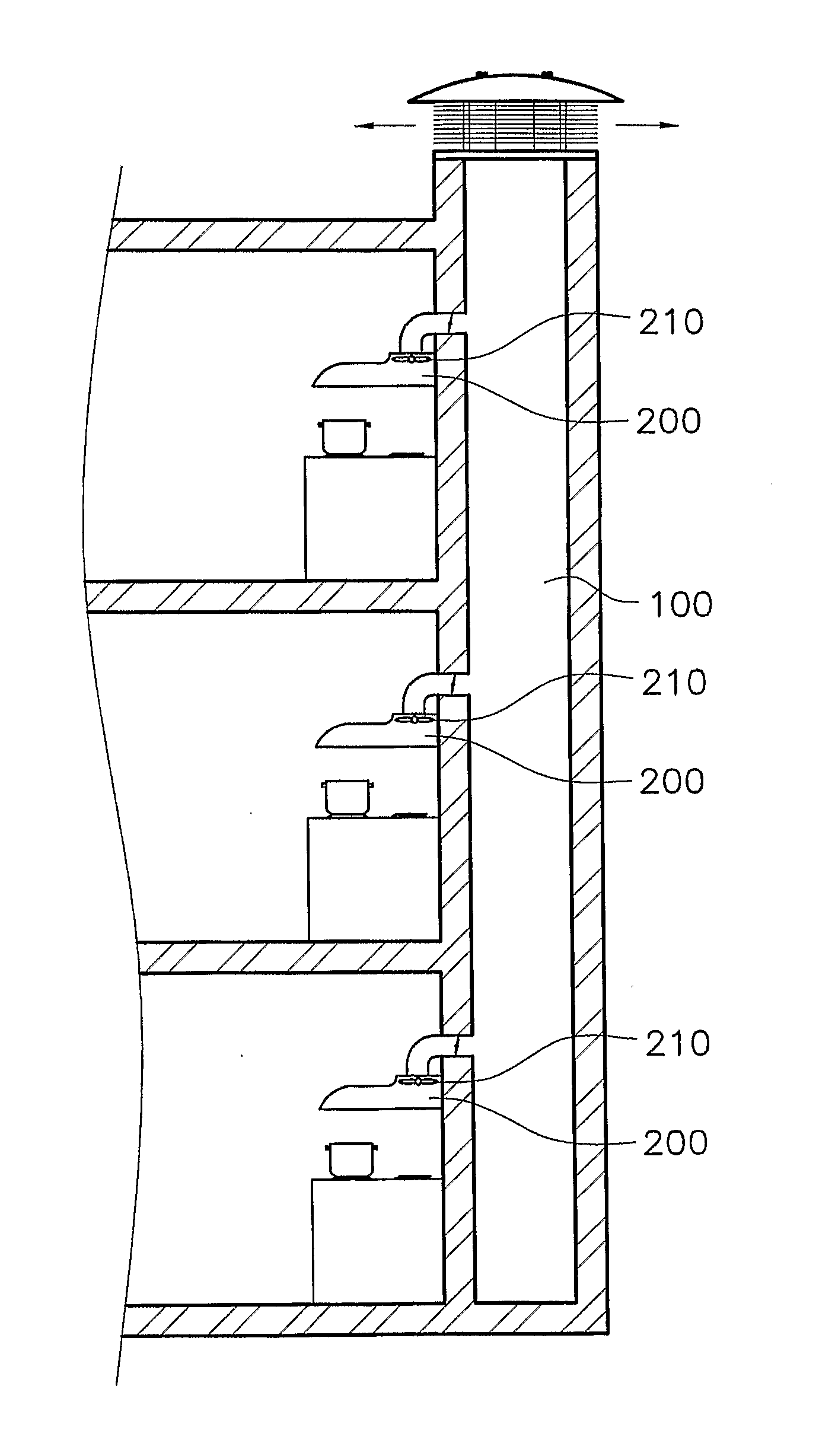

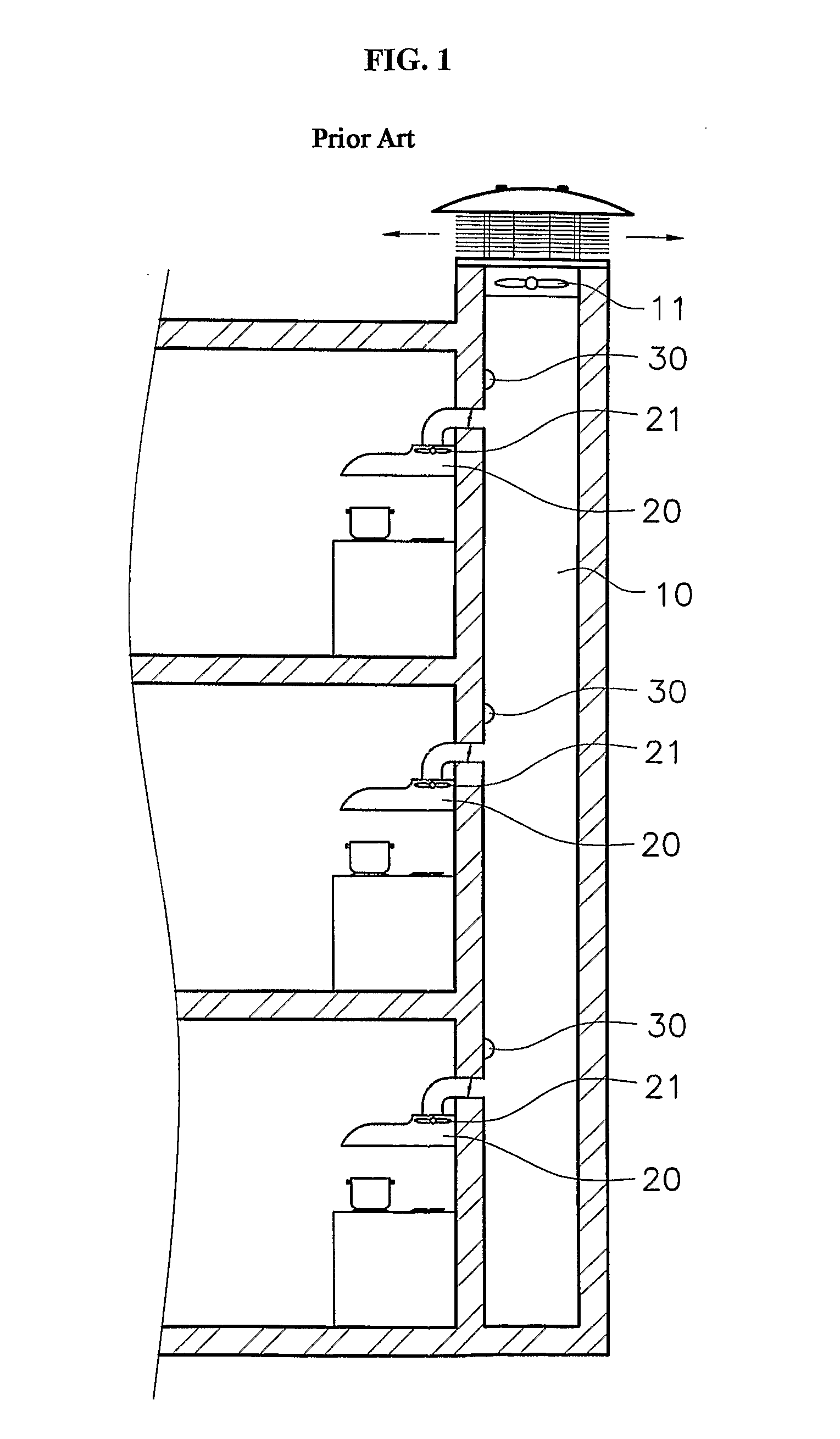

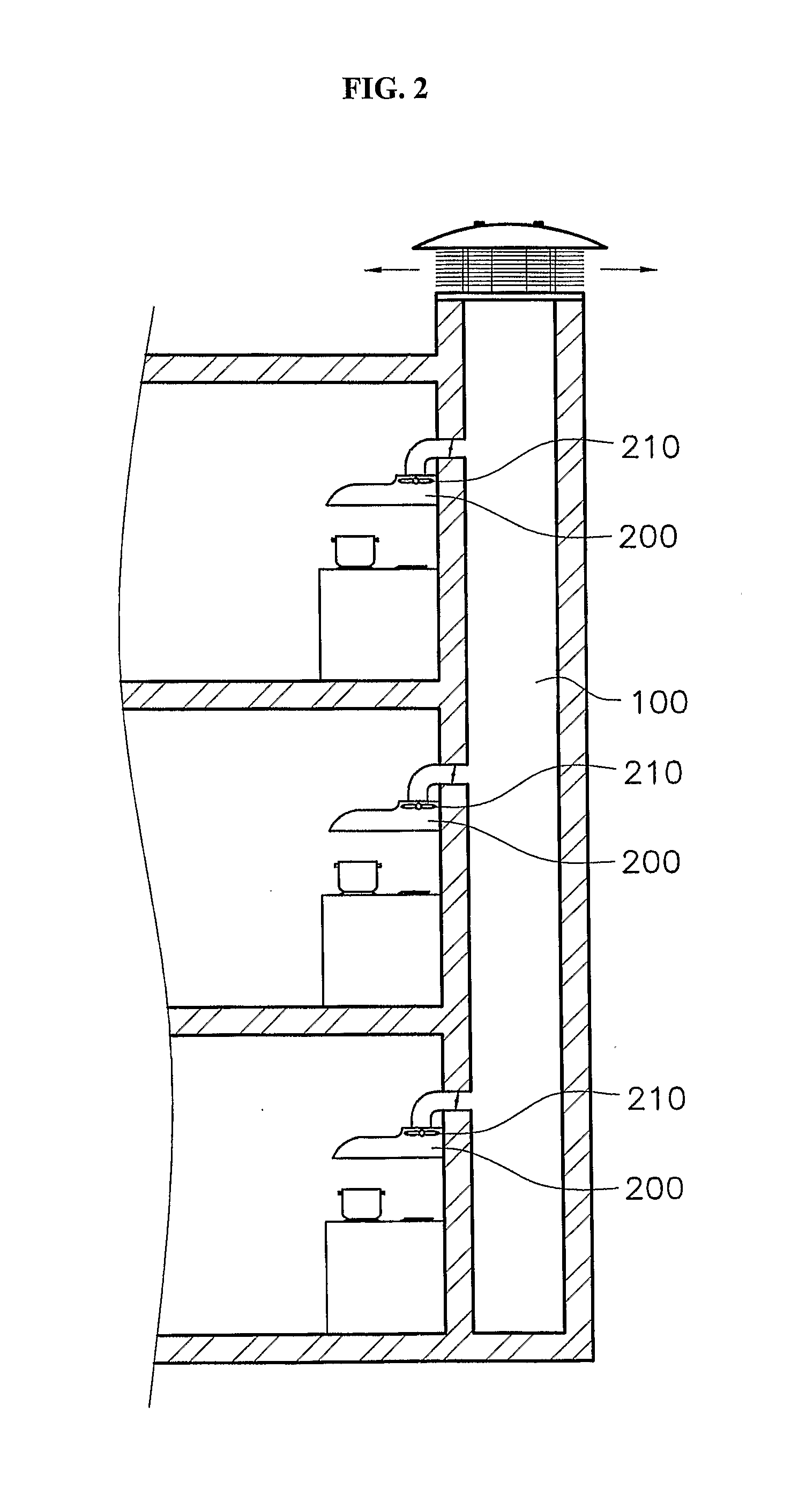

[0021]FIG. 2 is a side sectional view of a kitchen ventilation system to which a fan having a positive pressure-to-output characteristic according to the present invention is applied, and FIG. 3 is a circuit diagram of a fan driving circuit for use in a kitchen ventilation system to which a fan having a positive pressure-to-output characteristic is applied according to an embodiment of the present invention.

[0022]FIG. 4 is a graph illustrating load curves and operating points of the fan driving circuit for use in a kitchen ventilation system to which a fan having a positive pressure-to-output characteristic is applied according to an embodiment of the present invention, FIG. 5 is a circuit diagram of a fan driving circuit for use in a kitchen ventilation system to which a fan having a positive pressure-to-output characteristic is applied accor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com