UDD dragline bucket machine and control system

a bucket machine and control system technology, applied in mechanical machines/dredgers, soil shifting machines/dredgers, constructions, etc., can solve the problems of longer wear life of the front hoist line, achieve maximum carrying power of additional motors, maximize the equalization of the wear of the hoist line, and facilitate the effect of accommodating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

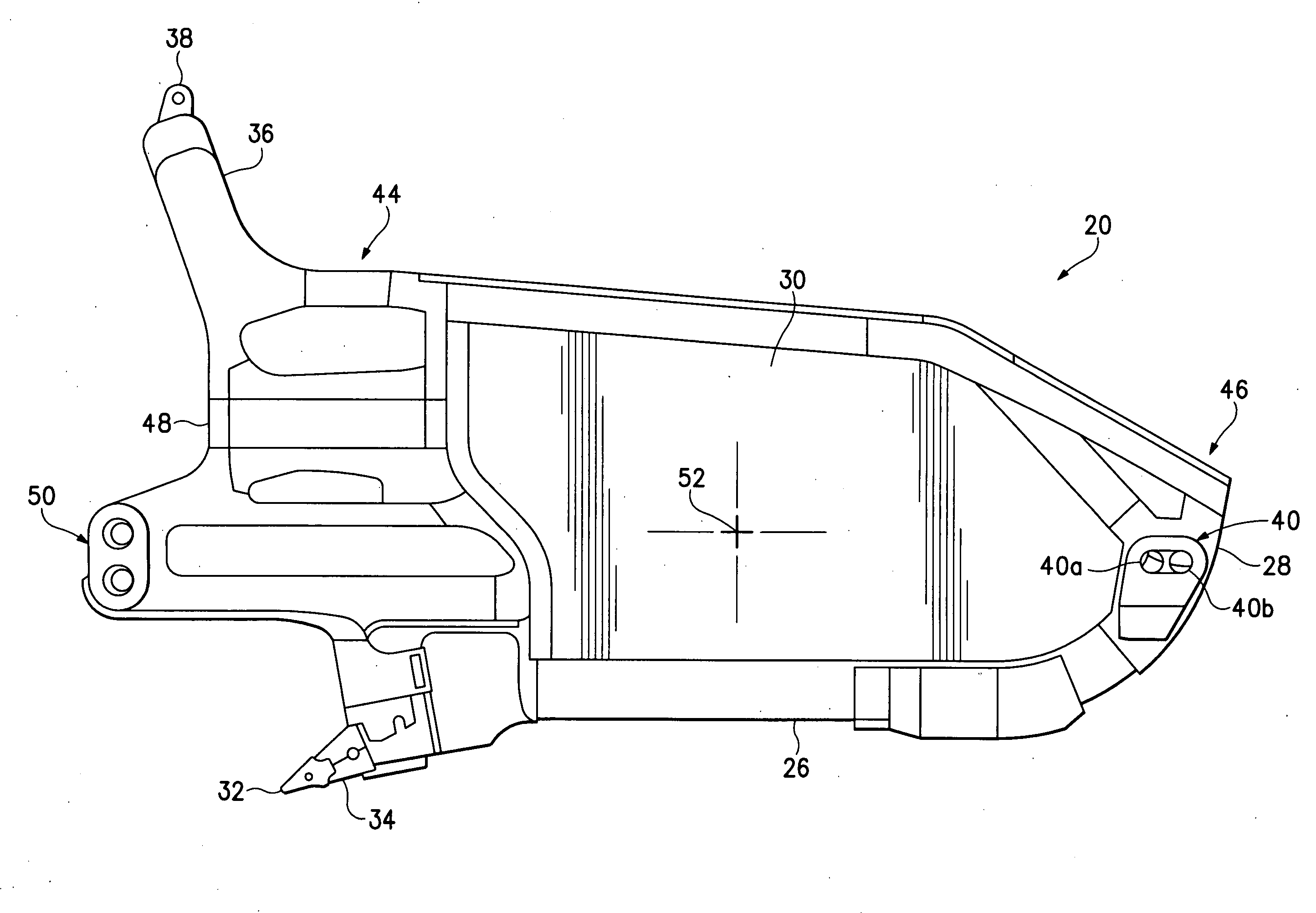

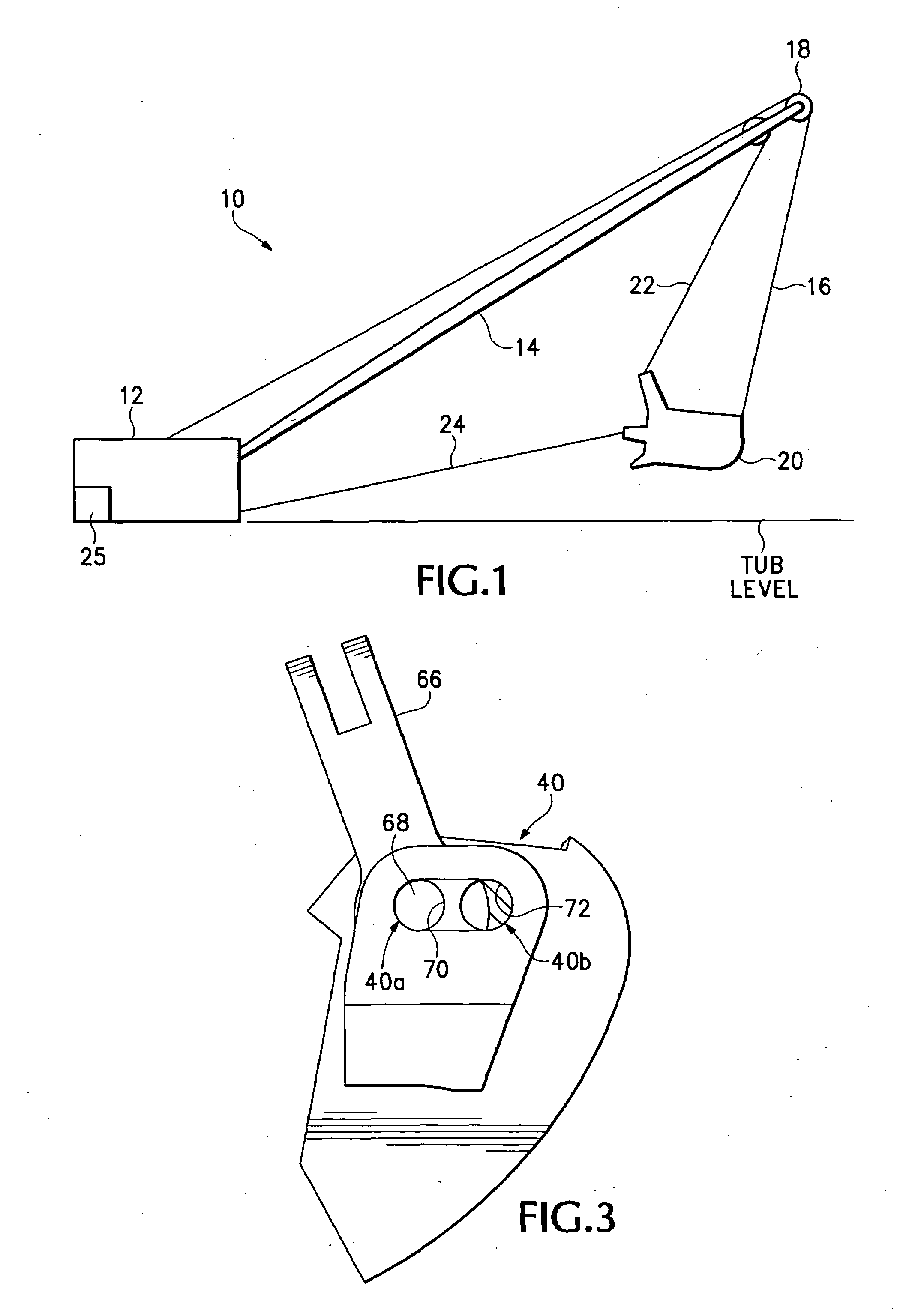

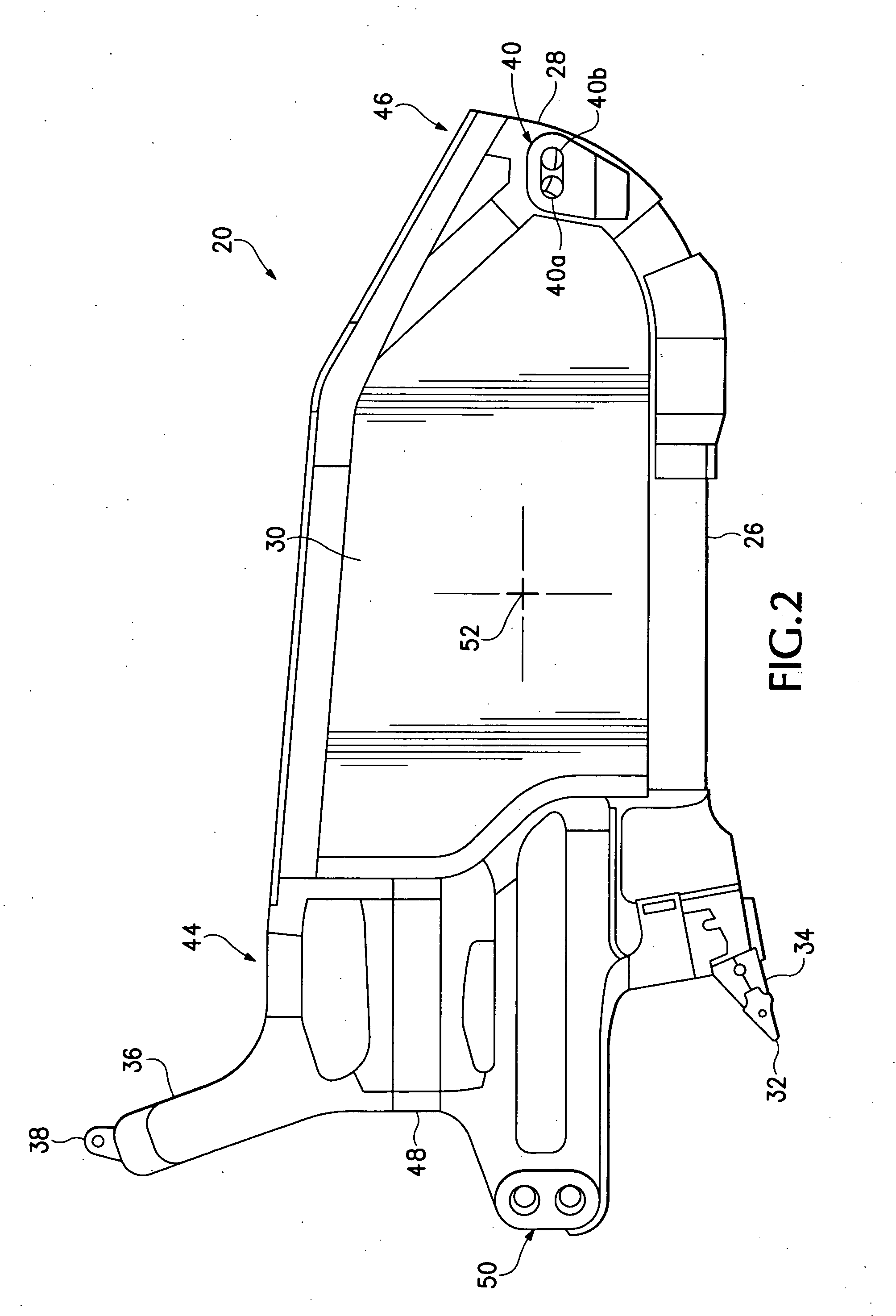

[0020]The present invention pertains to a UDD mining machine wherein the bucket is controlled by independently operated front and rear hoist lines as well as a drag line, such as disclosed in U.S. Pat. Nos. 6,705,031 and 6,826,466, both of which are incorporated herein by reference. Briefly, a UDD operation is a dragline mining operation wherein the bucket is controlled solely by the attachment of flaccid lines, such as ropes, cables or chains. With reference to FIG. 1, a UDD operation 10 includes a machine 12 situated at a base location that is typically at or near ground level. The machine includes an elongate boom 14 that extends over the mining site, which typically is a large pit. One or more rear hoist line 16 extends downward generally from a free end 18 of the boom to engage a rear portion of bucket 20. Similarly, one or more front hoist line 22 extends downward from boom 14 to connect to a front portion of bucket 20. Hoist lines 16, 22 operate independently to carry and dum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com