Semirigid, collapsible, cinchable utility sack with pockets

a utility sack and pocket technology, applied in the field of utility sacks, can solve the problems of impeded convenient storage of buckets, unsuitable reuse, and most lack of convenient carrying, and achieve the effects of eliminating dependency, facilitating collapsibility of bags, and preventing spillage of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

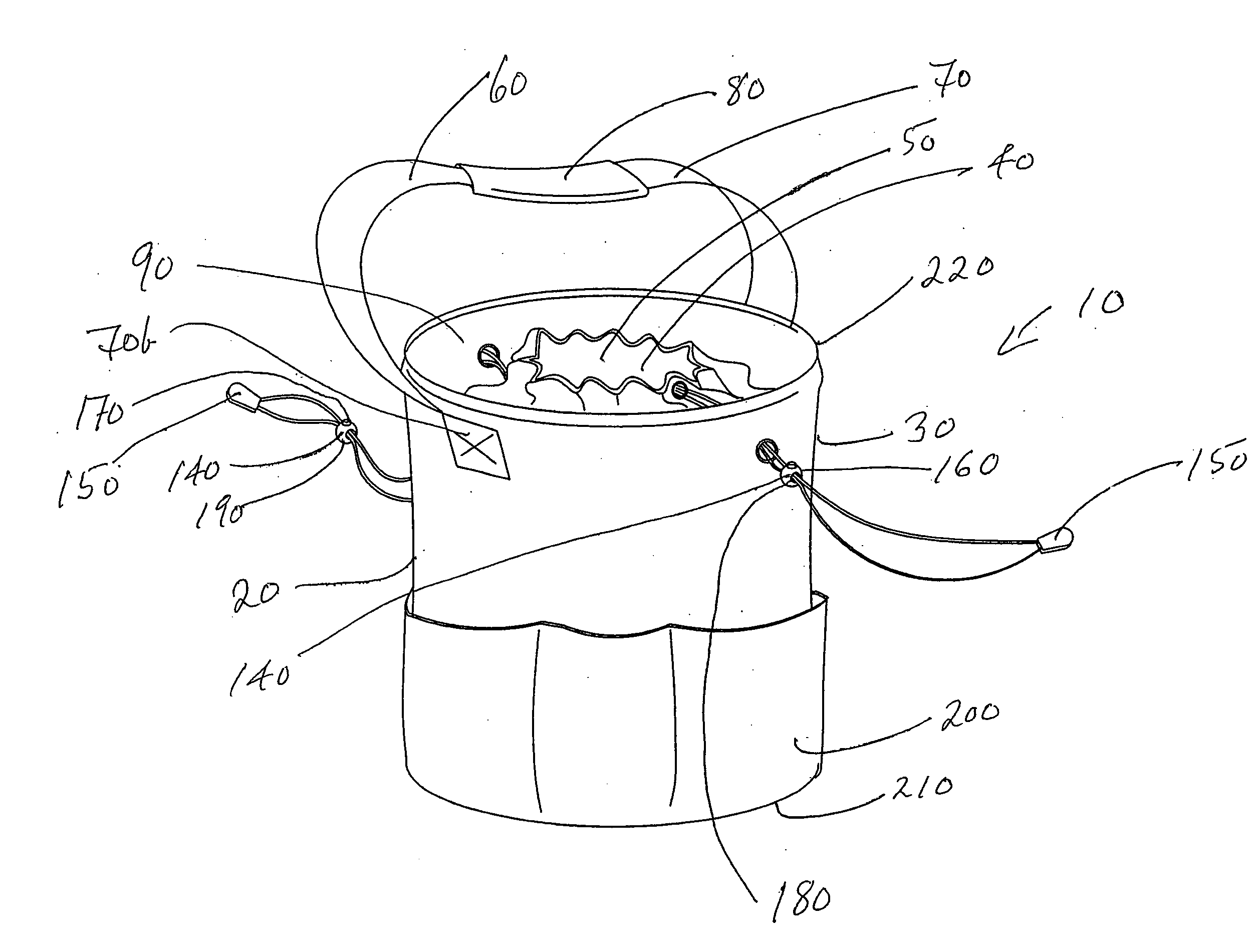

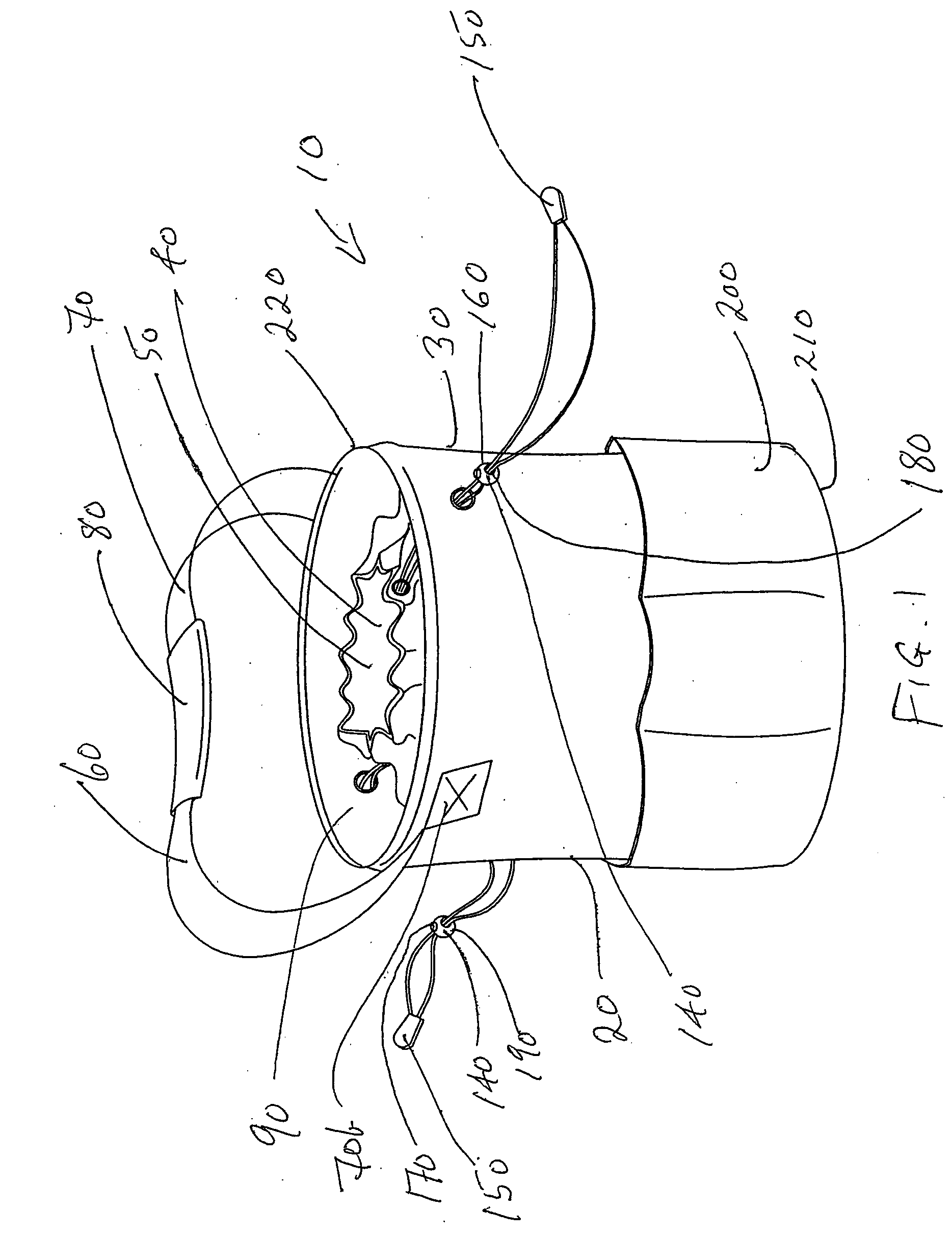

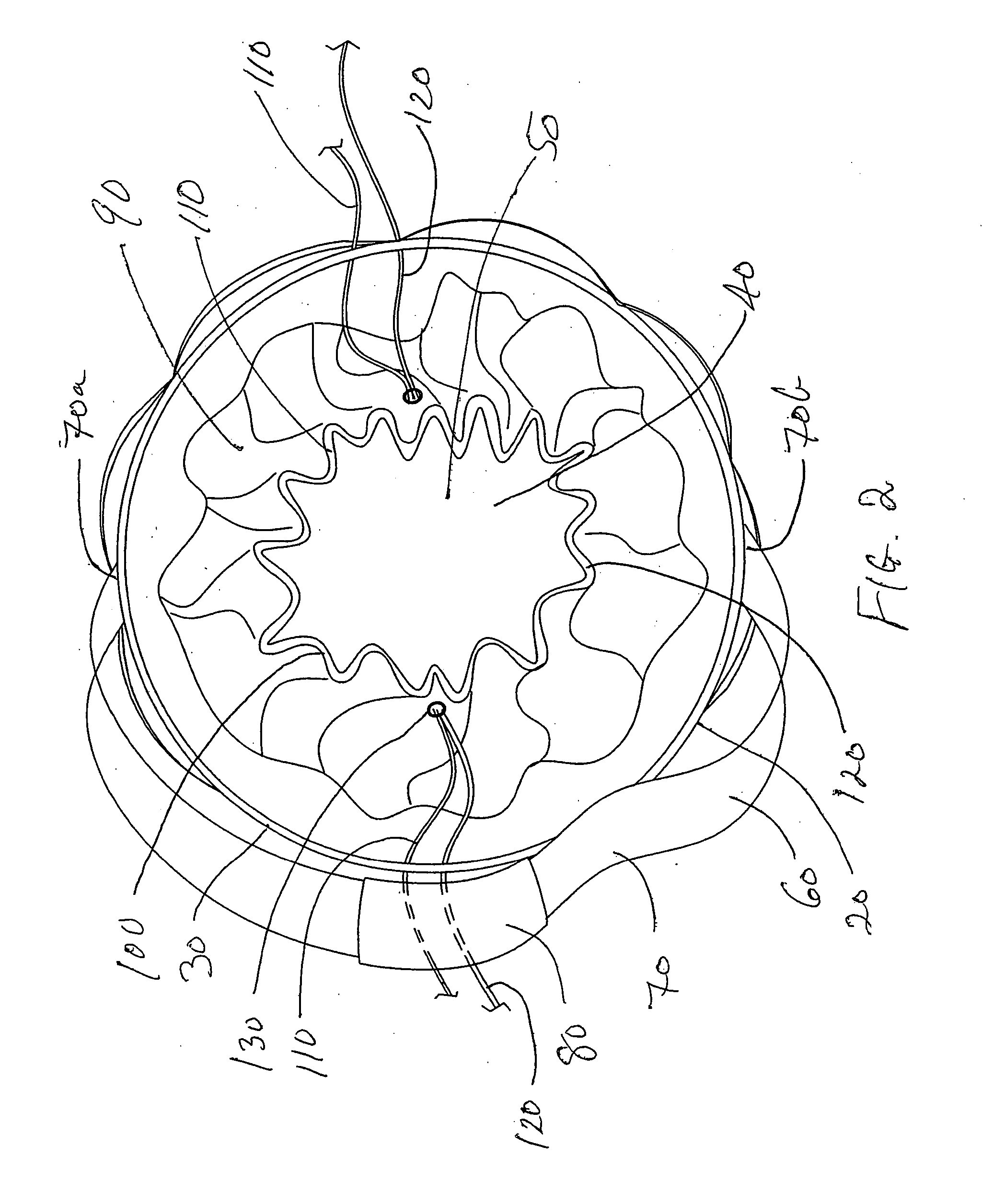

[0025] In describing the preferred and selected alternate embodiments of the present invention, as illustrated in FIGS. 1-3, specific terminology is employed for the sake of clarity. The invention, however, is not intended to be limited to the specific terminology so selected, and it is to be understood that each specific element includes all technical equivalents that operate in a similar manner to accomplish similar functions.

[0026] Referring now to FIGS. 1-3, the present invention in a preferred embodiment is a semirigid, collapsible, cinchable utility sack with pockets, wherein utility sack 10 preferably comprises body 20 of generally cylindrical construction, cinchable cover 90, handle 60 and pockets 200, wherein body 20 preferably has exterior 30, interior 40, bottom 210, and top periphery 220, and wherein interior 40 is preferably suitable for containing therewithin, liquids, solids (dry or wet) and variously shaped articles. Body 20, cinchable cover 90, handle 60 and pocket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com