Crystal Device and Method for Manufacturing Crystal Device

a crystal device and manufacturing method technology, applied in the field of crystal devices, can solve the problems of low accuracy and reliability, and the vibration wb>1/b> shown in fig. 14 becomes a very serious problem, and achieves the effects of high accuracy, stable vibration characteristics, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

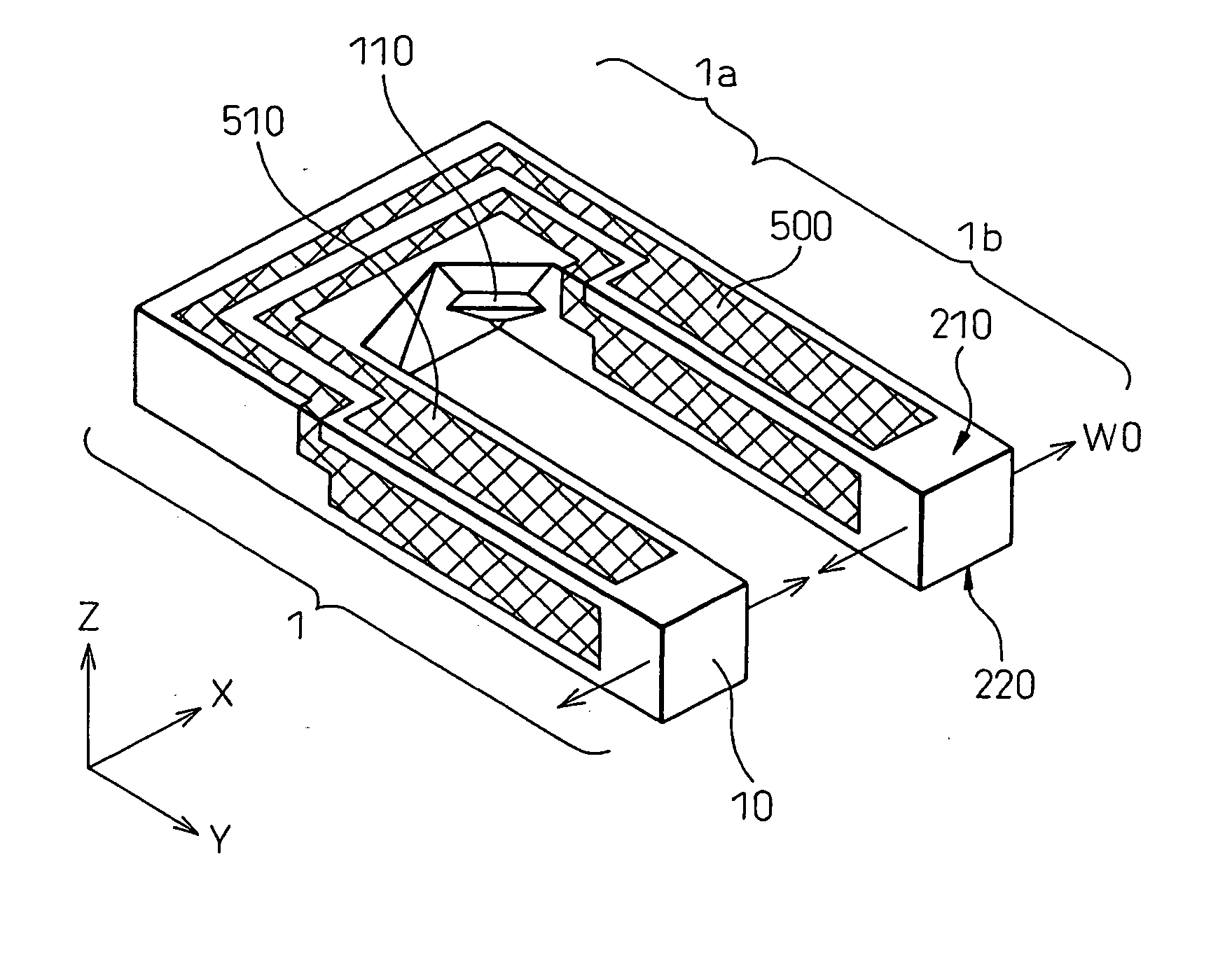

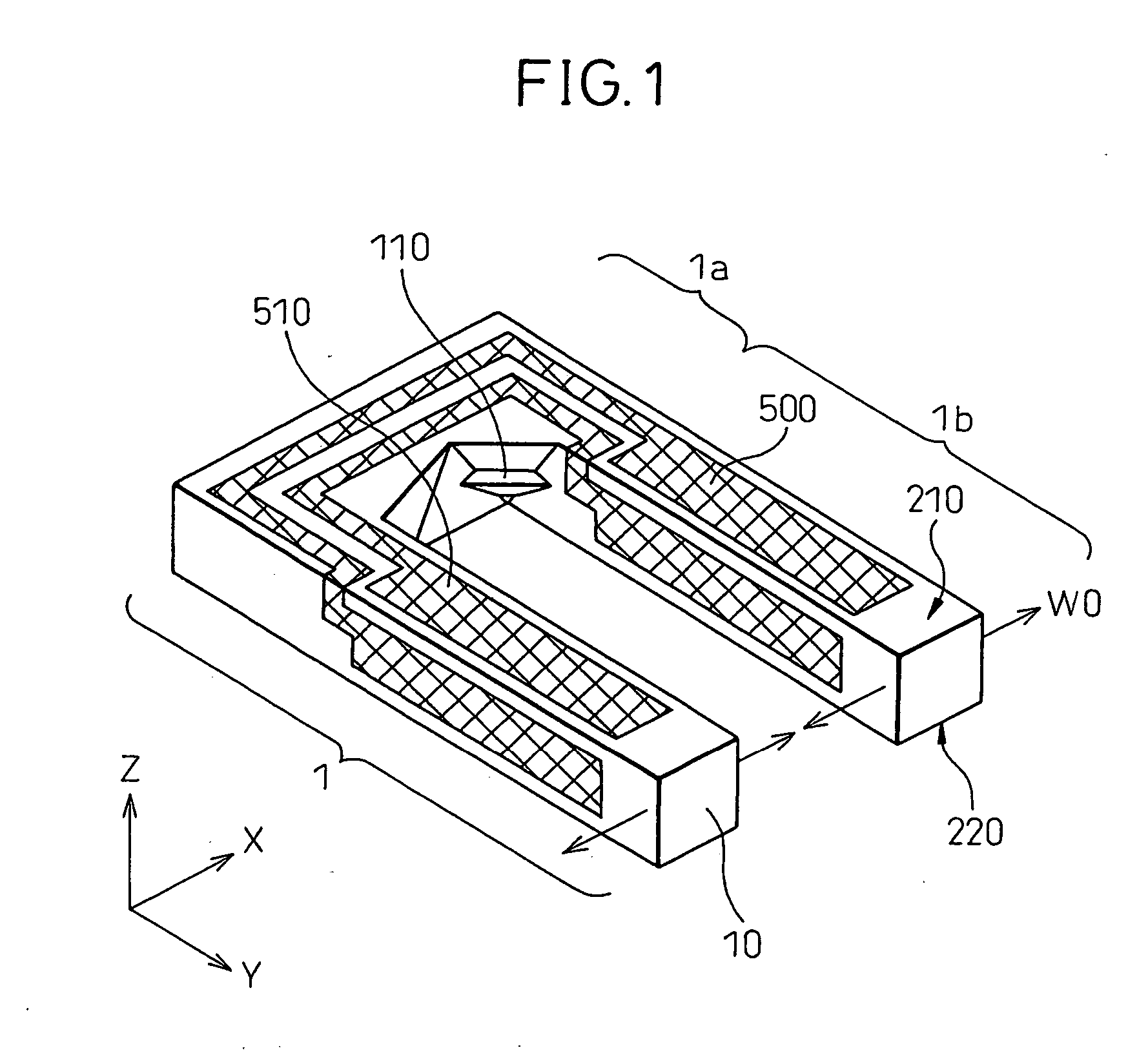

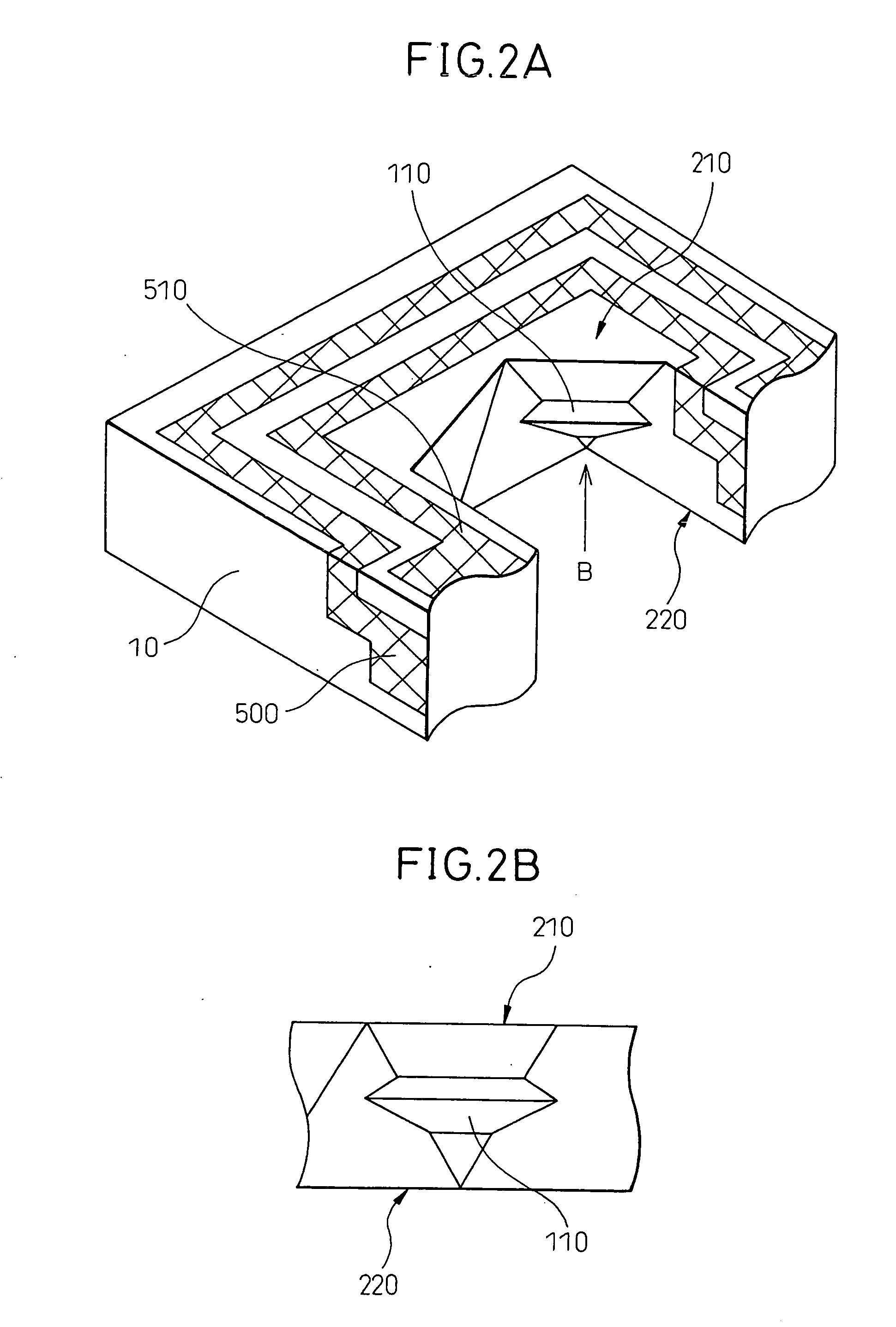

[0069]FIG. 1 is a diagram showing the structure of a crystal device 1 according to the present invention.

[0070] The crystal device 1 according to the present invention comprises a crystal plate 10 formed from a crystal, and electrodes 500 and 510. The crystal plate 10 is formed in the shape of a tuning fork which is made up of a base 1a and a plurality of vibrating prongs 1b protruding from the base 1a. The electrodes 500 and 510 are electrically separated from each other, and an electric field can be produced across the crystal plate 10 by applying different potentials to the respective electrodes. Since the crystal plate 10 is a piezoelectric material, the plate contracts or expands according to the direction of the applied electric field; this contracting / expanding motion causes the vibrating prongs 1b to vibrate. When a voltage is applied between the electrodes 500 and 510 of the crystal device 1, the two vibrating prongs 1b produce vibrations W0 along the X-axis direction.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shapes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com