Endoscope washer disinfector and brush cassette detachably loaded to the same

a technology of endoscope washer and disinfector, which is applied in the direction of mechanical equipment, applications, lighting and heating apparatus, etc., can solve the problems of operator trouble, increase the work time required for the endoscope to be cleaned and disinfected, and easy adhesion of bacteria to the ducts, etc., to achieve the effect of ensuring a good cleaning performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

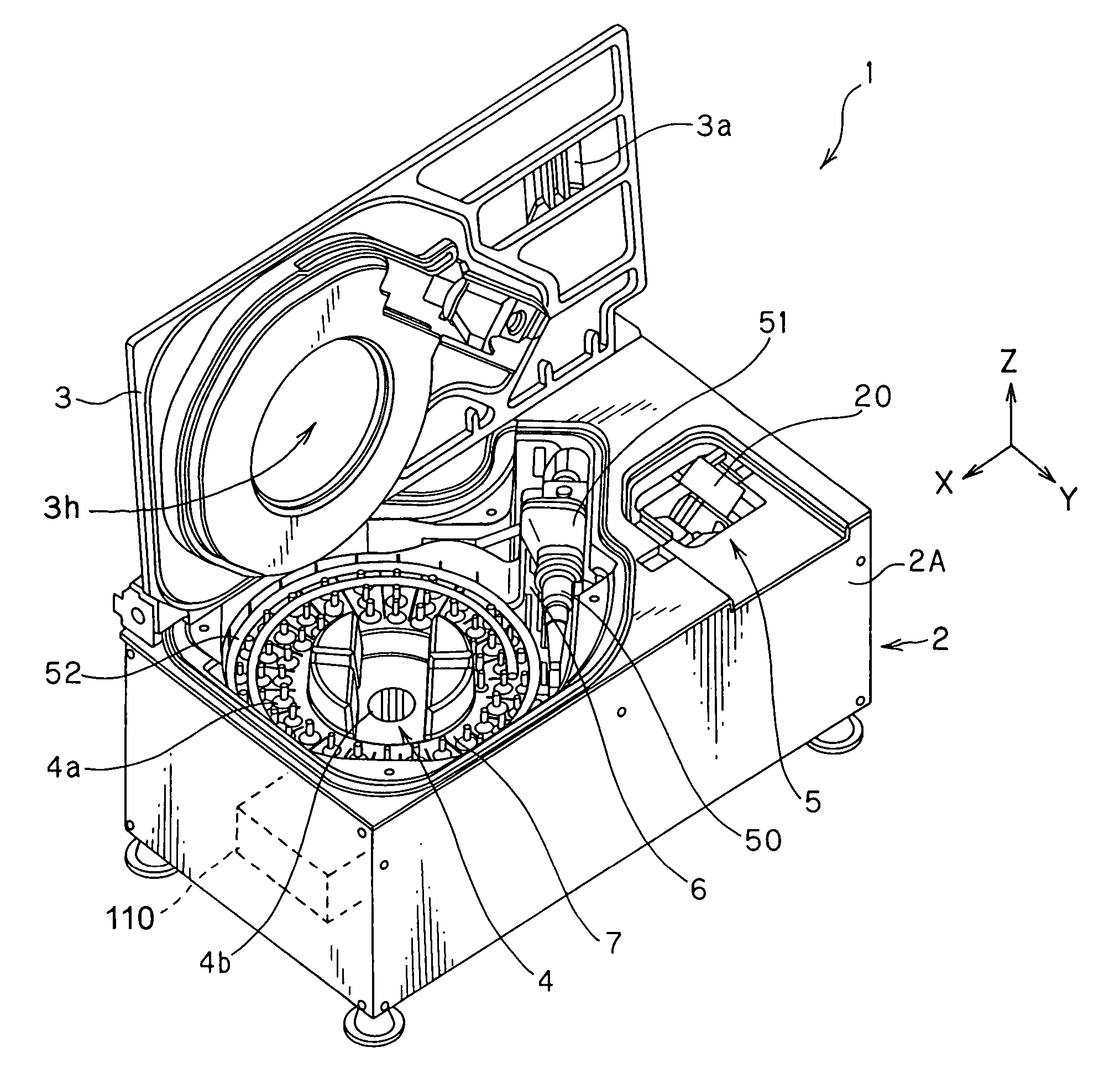

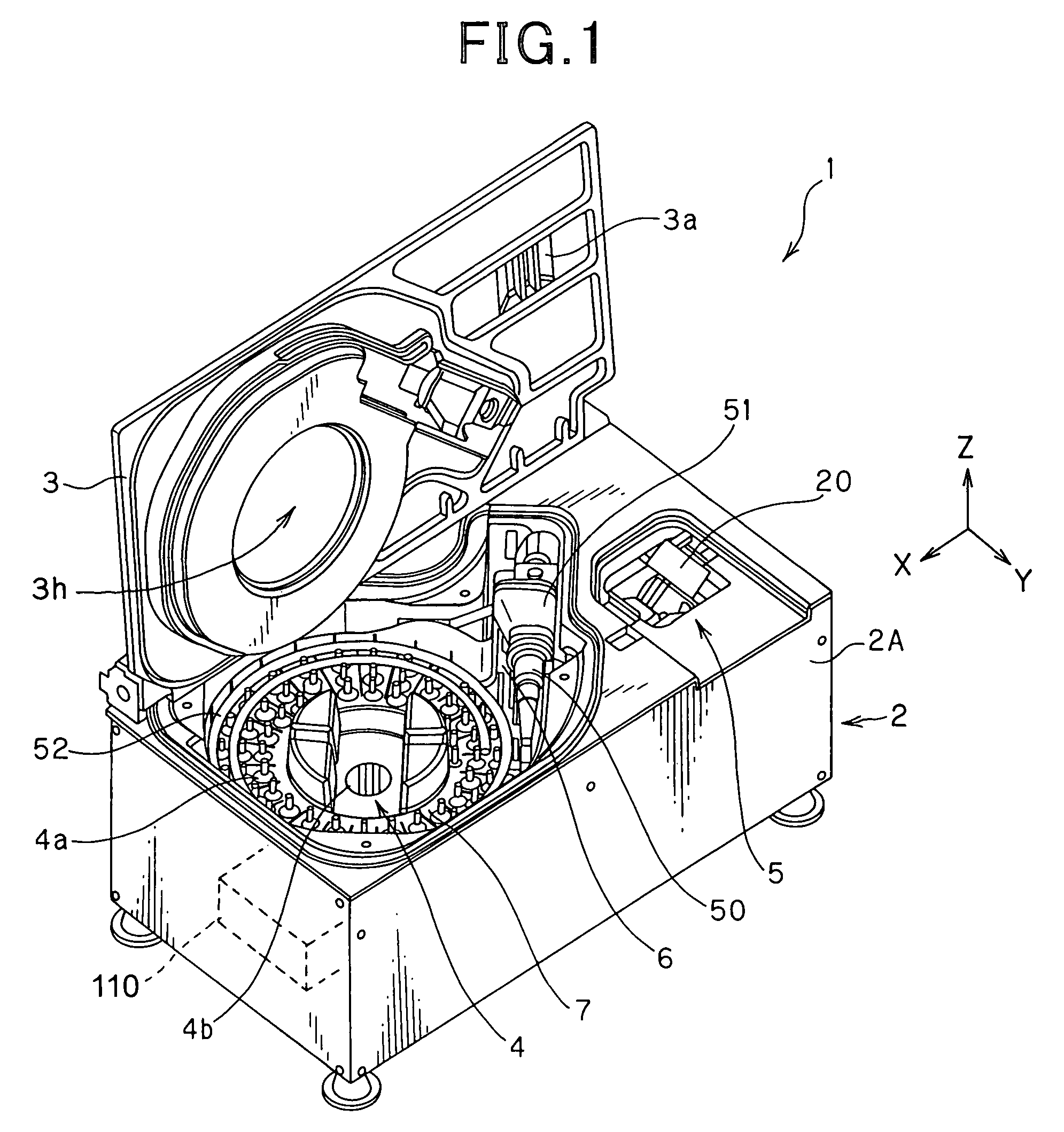

[0039] First, referring to FIGS. 1-9, a first embodiment of the endoscope washer-disinfector according to the present invention will now be described.

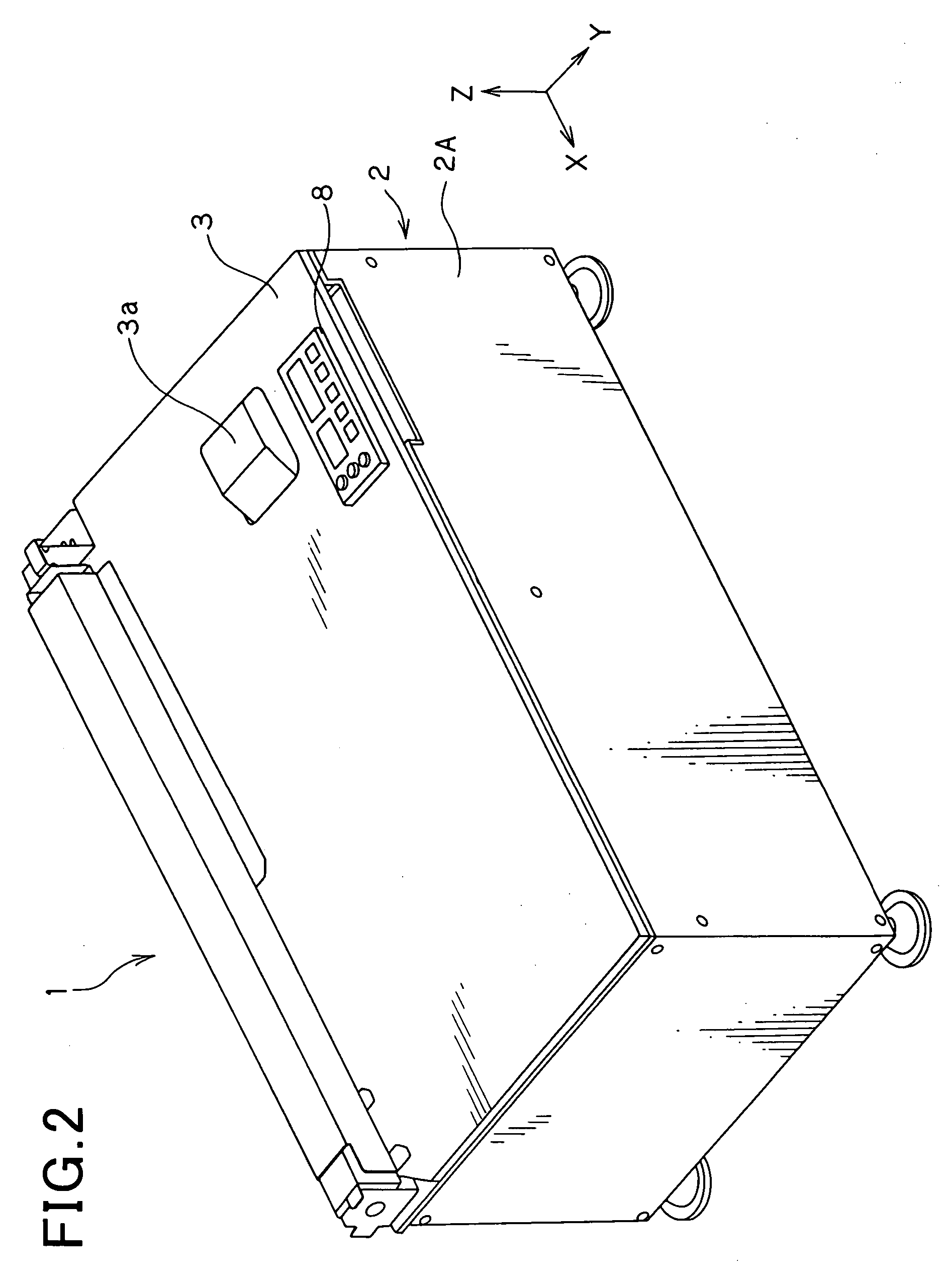

[0040]FIG. 1 shows an outlined appearance of the endoscope washer-disinfector 1 according to the present embodiment. As shown, the endoscope washer-disinfector 1 is constructed to have a main body unit 2, a top cover 3 serving as a cover member which can be opened and closed freely from and to the upper face of the main body unit 2, and a brush cassette 20 detachable to and from the main body unit 2 and formed for cleaning an endoscope 50. The main body unit 2 comprises, as its casing, a frame 2A which is formed into a substantial box shape. Inside the frame 2A, there are provided various mechanical and electric mechanisms for cleaning and disinfecting endoscopes. In the present embodiment, the terms “cleaning (or washing)” and “disinfecting” represent in meaning a term “processing” which includes various other steps, such as rinsing ...

second embodiment

[0100] Referring to FIGS. 10-17, an endoscope washer-disinfector according to the second embodiment will now be described.

[0101] The endoscope washer-disinfector according to the second embodiment differs from that described in the first embodiment in the shapes of the guide member and stoppers of the brush cassette and the shapes of the unlocking pines disposed at the loading part. Additionally, the unlocking pins themselves do not move the stoppers, but move the guide member, which is another different structure from that of the first embodiment. In the followings, the description will be given mainly to such differences. And, in the present embodiment, the same or identical components to those in the first embodiment will be given the same reference numerals as those in the first embodiment.

[0102] Incidentally, in FIGS. 13 and 14 later described, a guide member 135 and stoppers 136 are pictorially depicted, with their detailed structures omitted from their depiction.

[0103]FIG....

third embodiment

[0124] Referring to FIGS. 18-19, an endoscope washer-disinfector according to a third embodiment of the present invention will now be described.

[0125] The endoscope washer-disinfector according to the third embodiment differs from that of the second embodiment in the shape and mechanism of the unlocking pin. In the present embodiment, the same or identical components to those in the second embodiment will be given the same reference numerals as those in the second embodiment.

[0126]FIG. 18 shows part of a brush cassette 20B adopted by an endoscope washer-disinfector according to this third embodiment. As shown in FIG. 18, the brush cassette 20B has a roller accommodating portion 22 in which an inner chamber 22i is formed by a casing 22g. In the chamber 22i, a driving roller 34, a guide member 235 serving as guide means, and stoppers 236 serving as locking (fixing) means are mounted.

[0127] The guide member 235 is disposed to tightly hold the cleaning brush 100 with the driving roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com