Basalt continuous filament insulating and fire-resistant material and sleeves and methods of construction thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

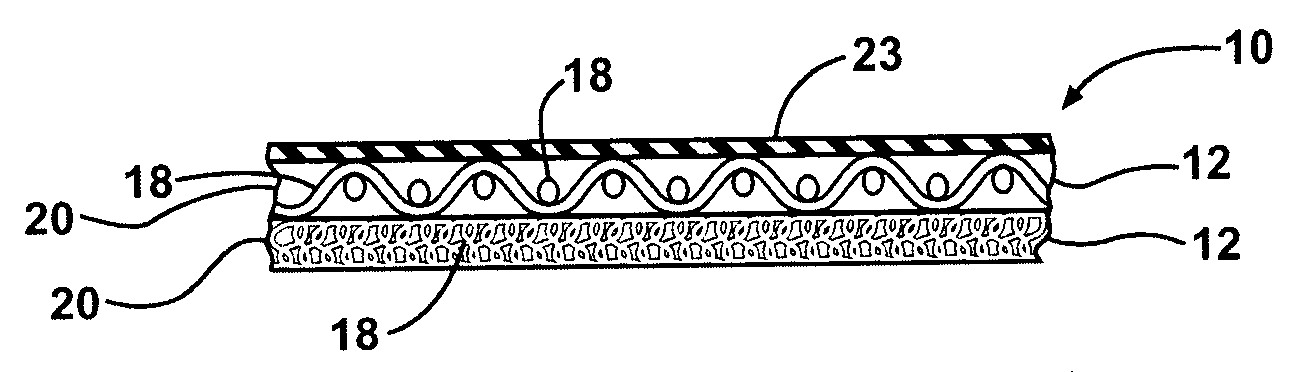

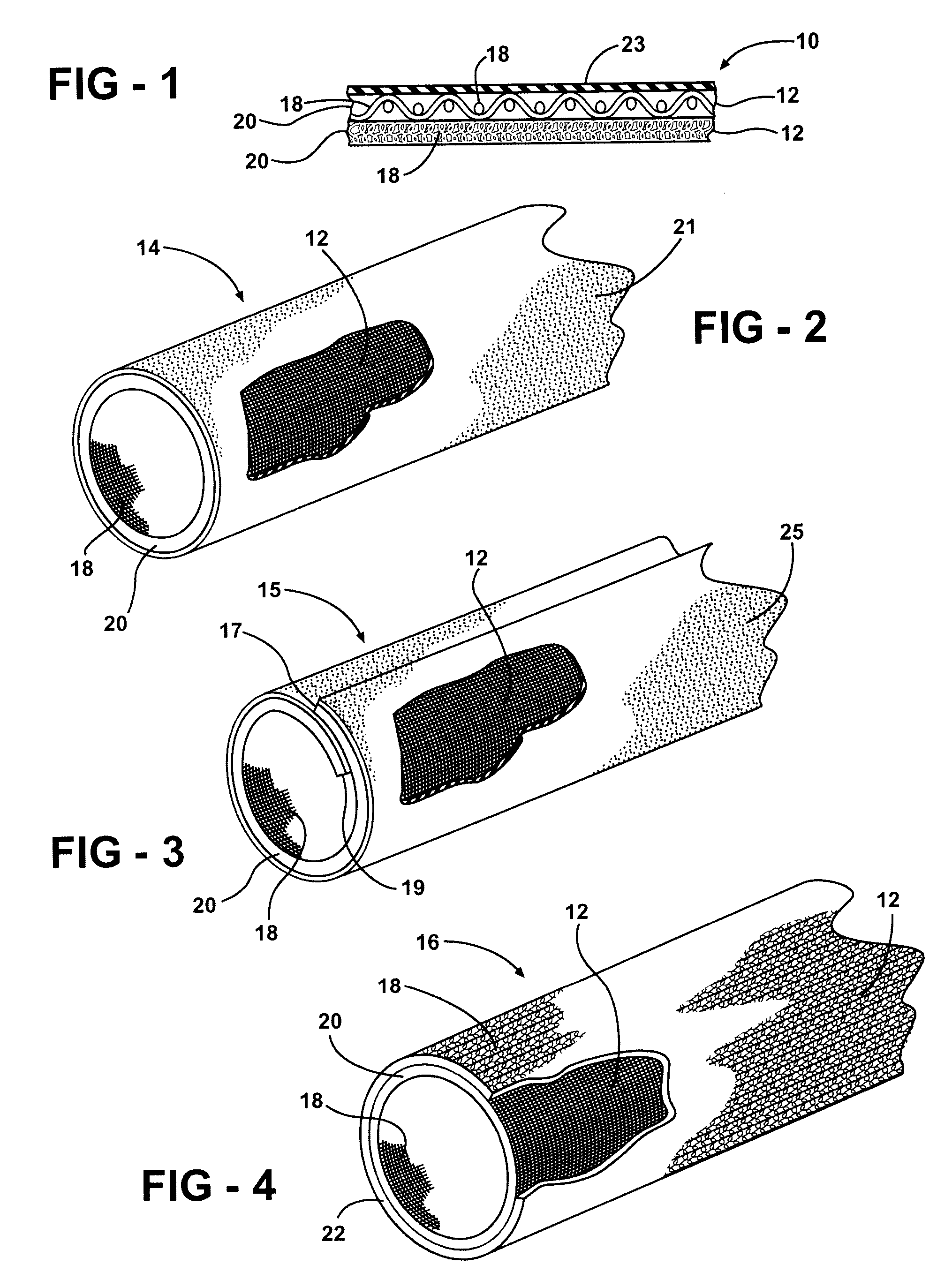

[0017]Referring in more detail to the drawings, FIG. 1 illustrates a textile insulating material 10 constructed from a plurality of basalt continuous filaments 12 in accordance with one presently preferred embodiment of the invention. The basalt continuous filaments 12 are fire-resistant and can provide thermal protection against extremely high (e.g., 760° C.) and extremely low temperatures (e.g., −260° C.) as well. A fabric sheet, panel, sleeve or other construction fabricated with the interlaced continuous basalt filaments 12 in accordance with the invention is superior to, and may be used to supplement or replace, many insulating and fire-resistant materials in use today. As non-limiting examples, sleeves 14, 15, 16 are shown in FIGS. 2-4, respectively, wherein the sleeves 14, 15, 16 are fabricated at least in part from the basalt continuous filaments 12 and, thus, may be used to insulate pipes exposed to extremely high heat (such as exhaust pipes having temperatures of 500° C. t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com