Method of riser deployment on a subsea wellhead

a wellhead and riser technology, applied in the direction of drilling rods, drilling casings, drilling pipes, etc., can solve the problems of time-consuming repositioning of floating rigs, inherent unpredictability of tidal forces both in strength and direction, and achieve the effect of reducing or eliminating the effect of wave action and less effor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

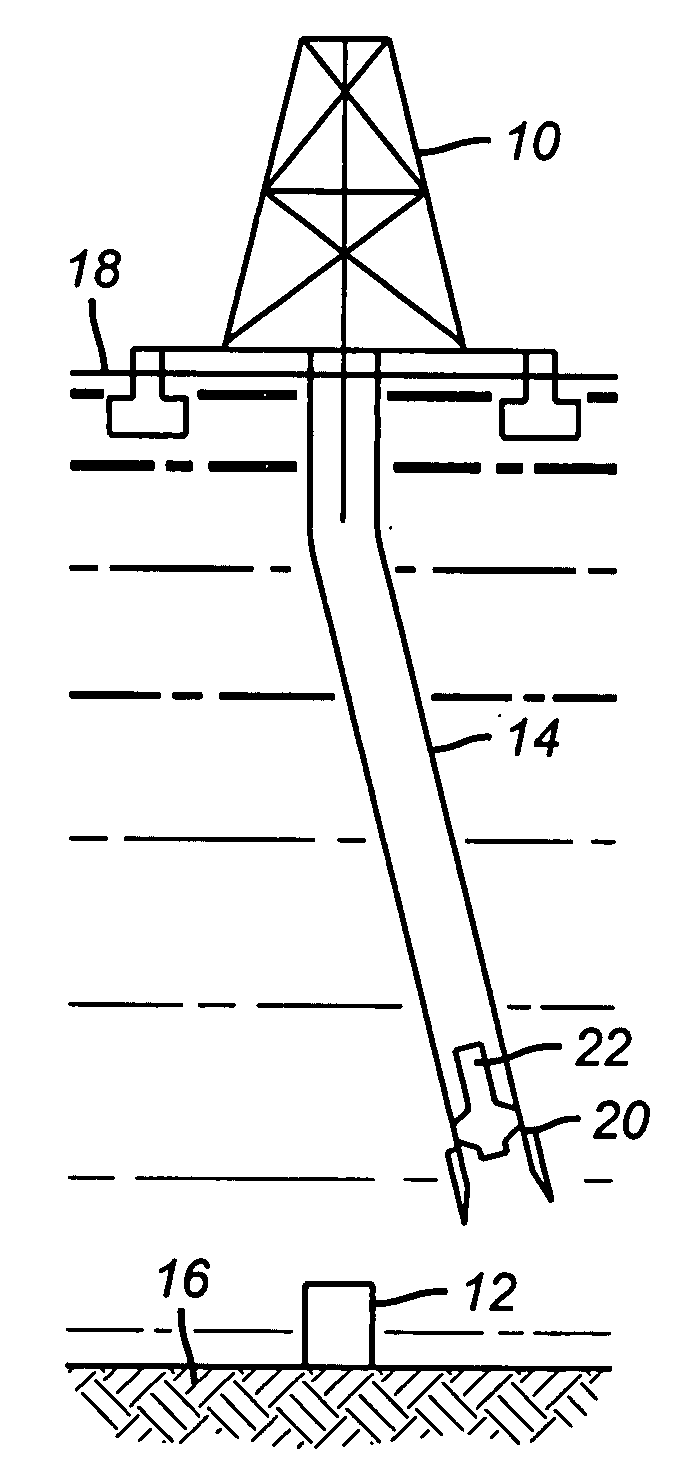

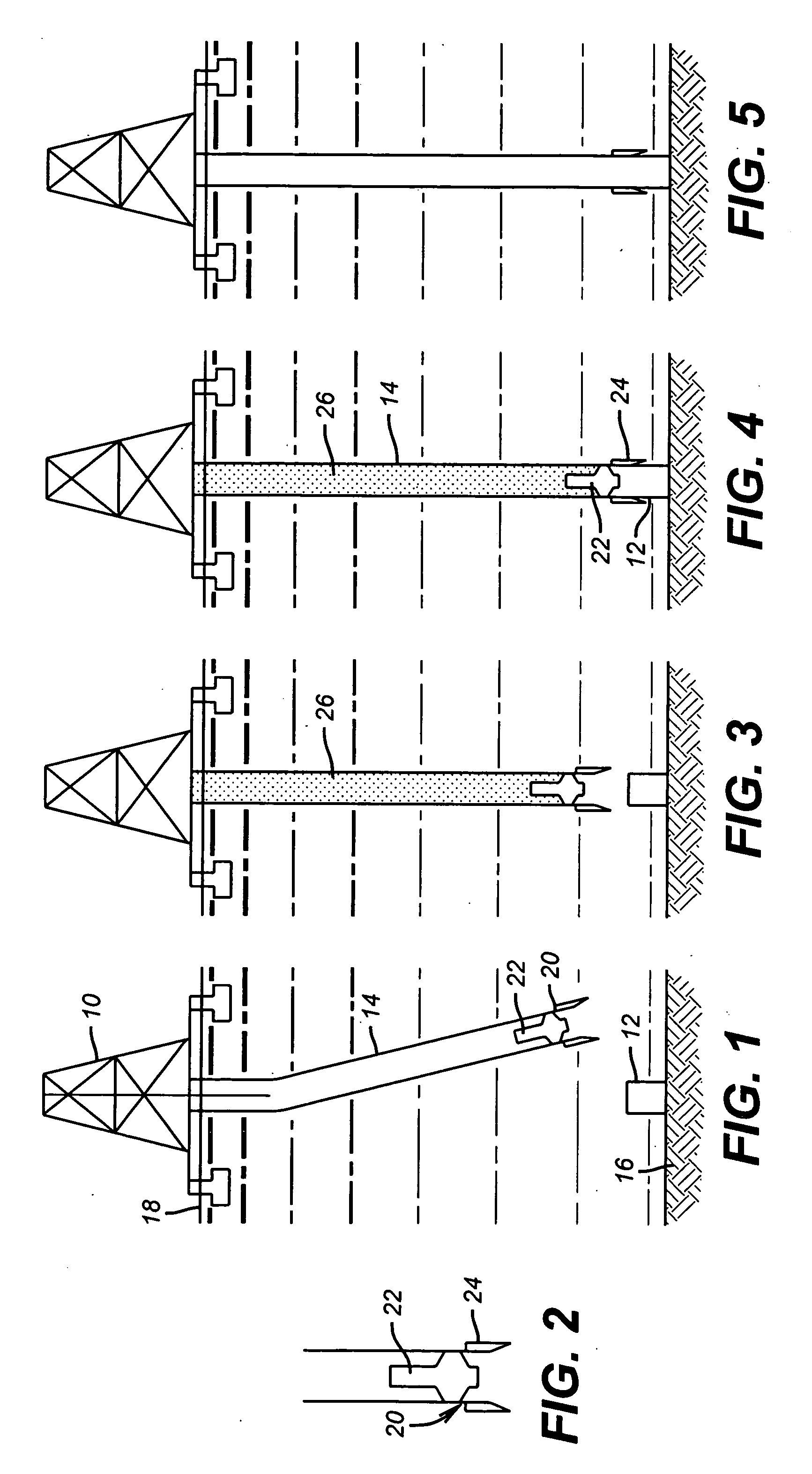

[0010]FIG. 1 shows a floating rig 10 set over a subsea wellhead 12 and supporting a riser 14 that is being deflected by currents active between the sea bed 16 and the surface 18. Near the lower end 20 of the riser 14 is a plug 22 that can be installed when the riser string 14 is assembled or later after it is fully assembled by running it in using a variety of known techniques. In the event the plug 22 is initially installed in the lowermost joint or joints of the riser string 14, drilling mud or seawater, for example, can be added above the plug 22 as each stand of riser pipe is connected at the surface and lowered in. FIG. 2 shows the lower end 20 closer up showing the plug 22 and schematically illustrating the connecting hardware 24 to attach to the wellhead 12. The plug can be deployed or dropped into the riser 14 and displaced with heavy fluid to a seat within the riser 14. Alternatively, the plug can be in position at the lower end of the riser but not seated off so as to allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com