Break-away multi-purpose flooring transition

a multi-purpose, transition technology, applied in the direction of roof tools, structural elements, metal sawing apparatus, etc., can solve the problems of difficulty in covering the gap that may be formed, problems encountered with conventional edge molding, etc., to enhance or supplement the fit and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

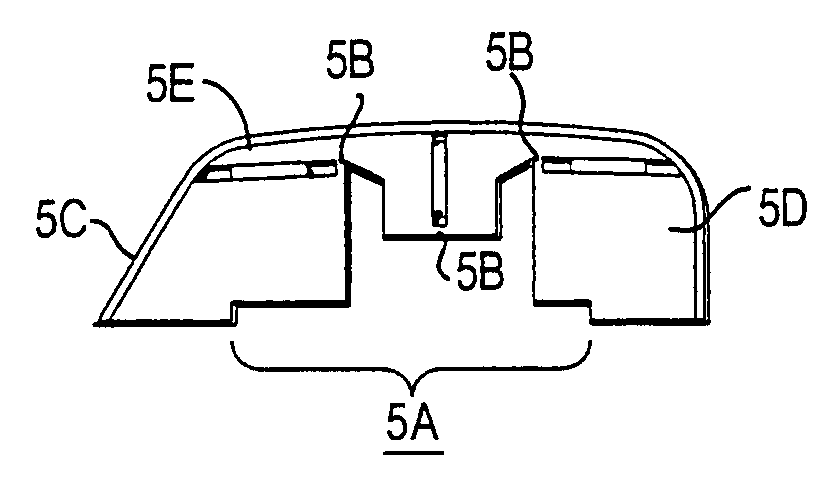

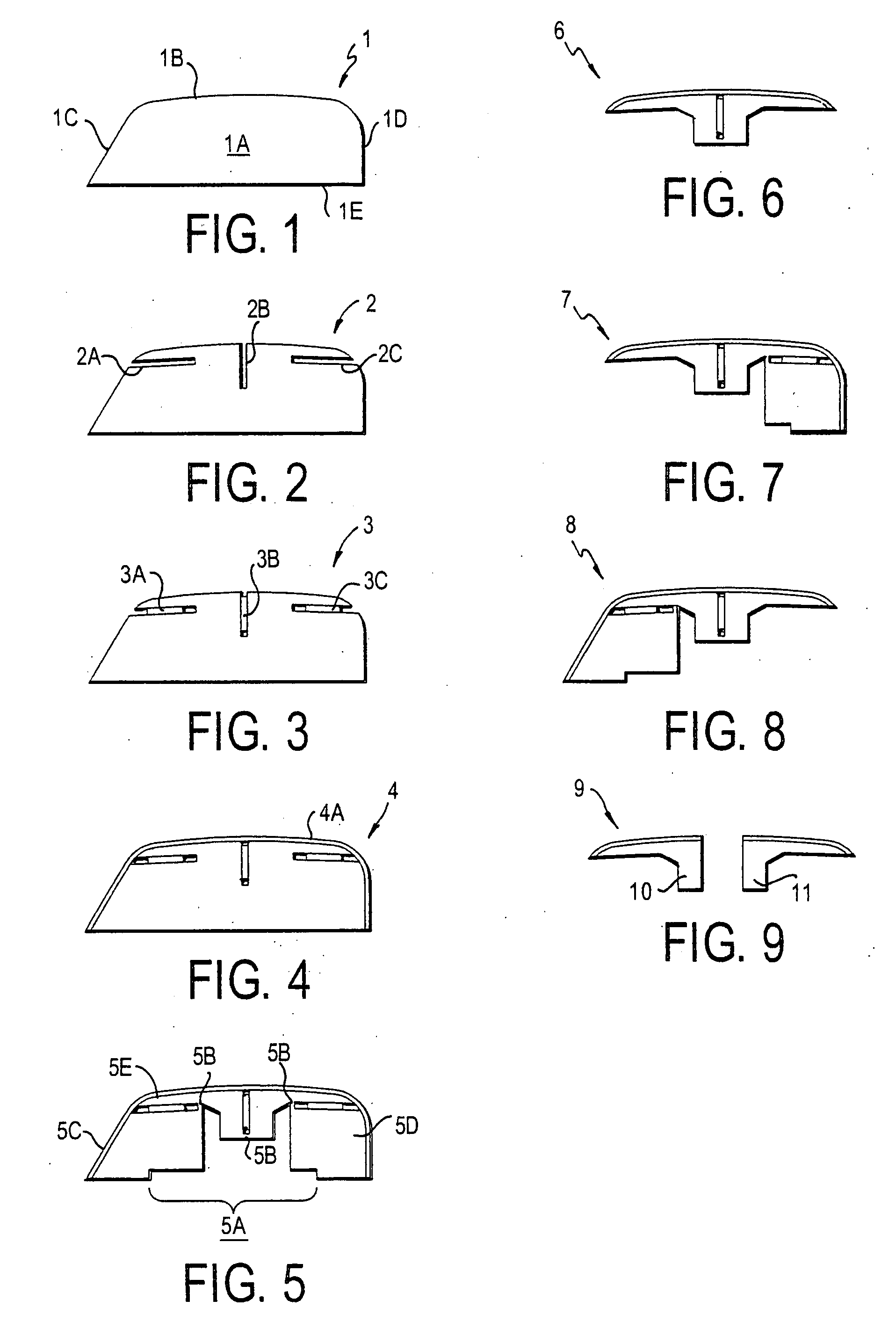

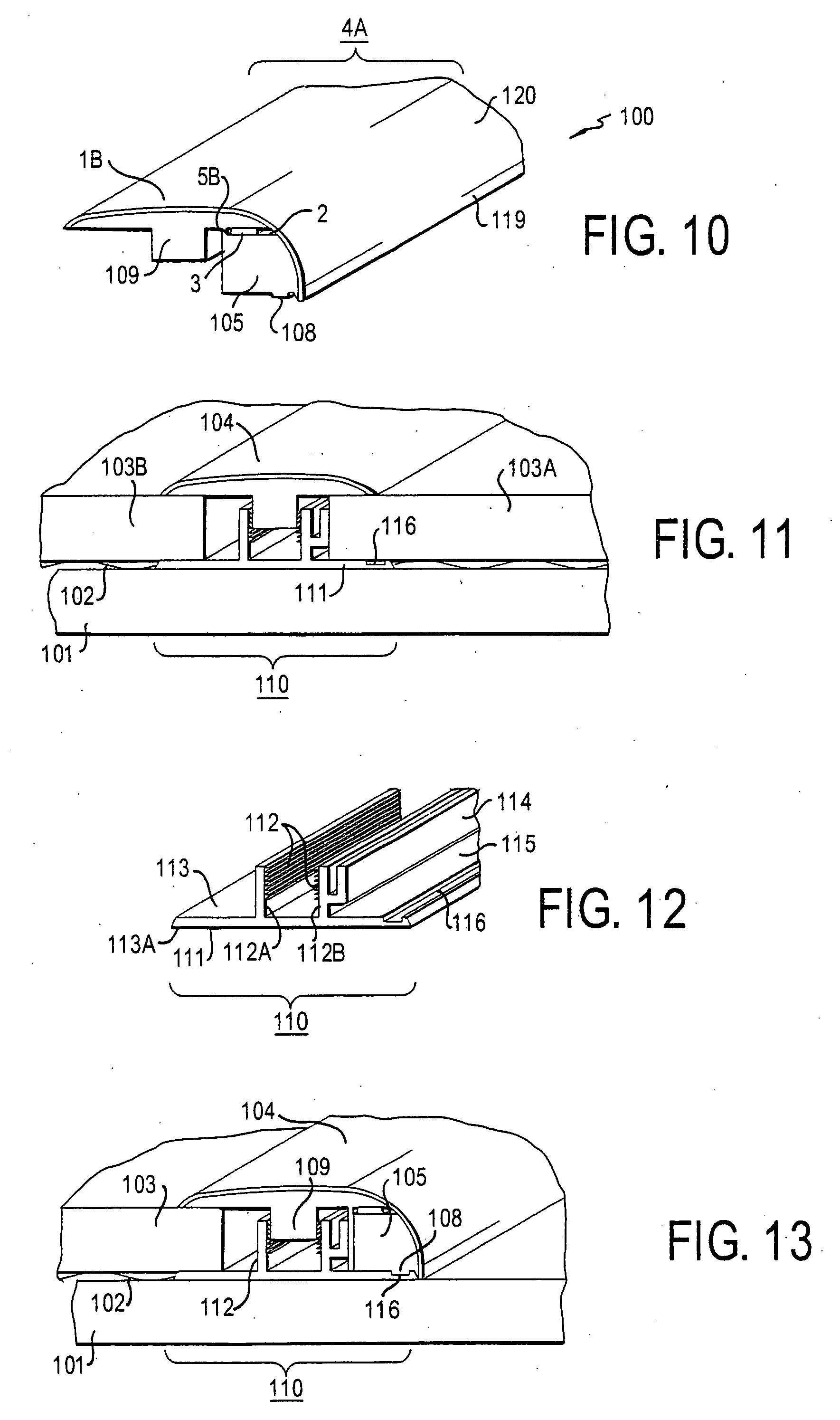

[0061]FIG. 1 shows a structure 1, from which the present invention can be formed. Structure 1 typically has a core 1A, an upper face 1B, a first lateral face 1C, a second lateral face 1D and a lower face 1E.

[0062] Preferably, core 1A is formed from a fiberboard, such as high-density fiberboard (HDF) or medium-density fiberboard (MDF), plastic, wood, engineered wood, metal, composites, gypsum, high-density fiber reinforced plaster, or other natural or synthetic material such as cork, or any additional material, such as described in U.S. Pat. No. 6,860,074, herein incorporated by reference in its entirety. Preferred plastics include extrudable thermoset and thermoplastic resins, the latter including high density olefins and polyvinylchloride. In preferred embodiments of the invention, the core 1A is unitary, i.e., it is a single piece / unit, not a multi-piece element, held together by glues, adhesives, joints, etc.

[0063] The decorative outer face can have a variety of finishes, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com