Dual field of view lens system

a lens system and dual field of view technology, applied in the field of optical lens systems, can solve the problems of insufficient robustness of the typical commercial zoom and focus lens mechanism, the inability to repair or replace the failure of the commercial lens system, and the increase of the cost, volume and mass of having multiple cameras and lens systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

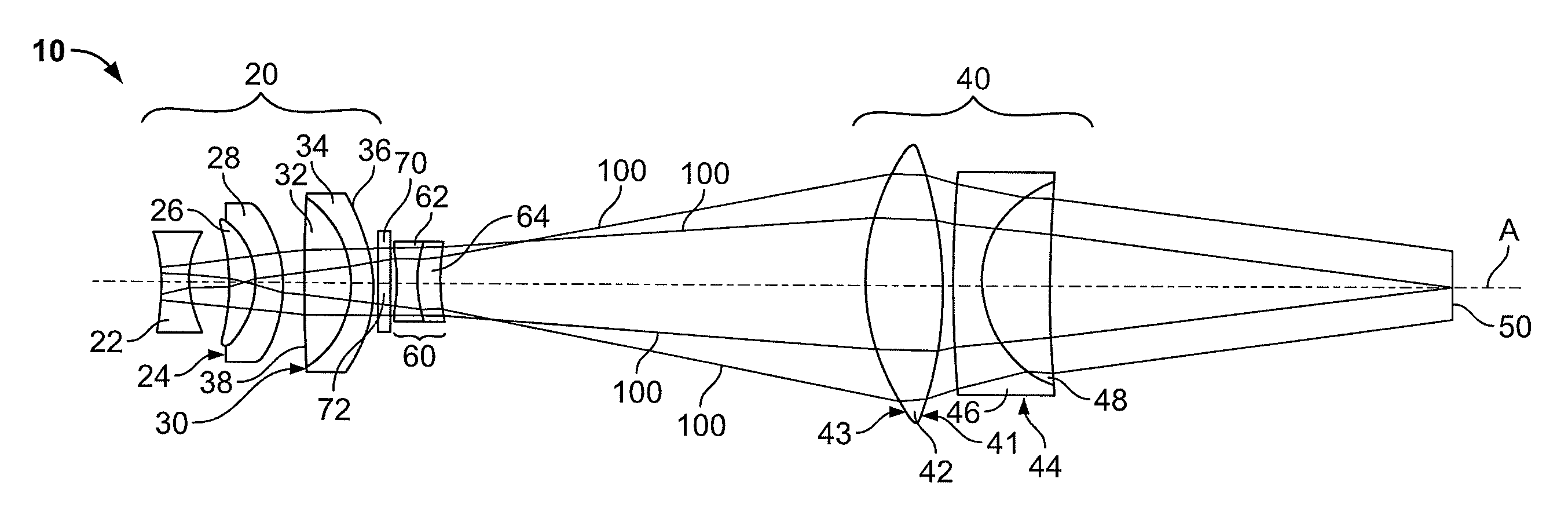

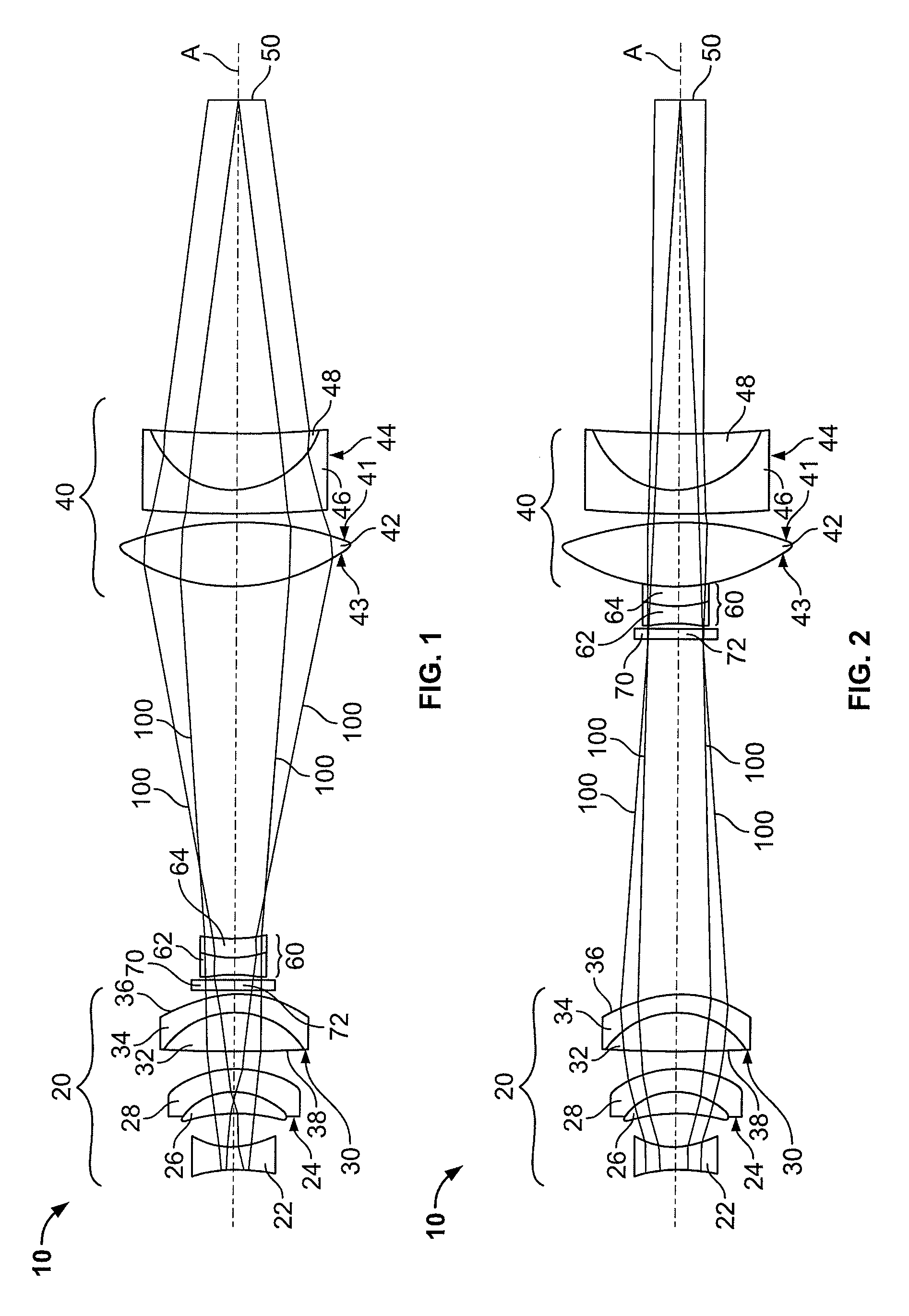

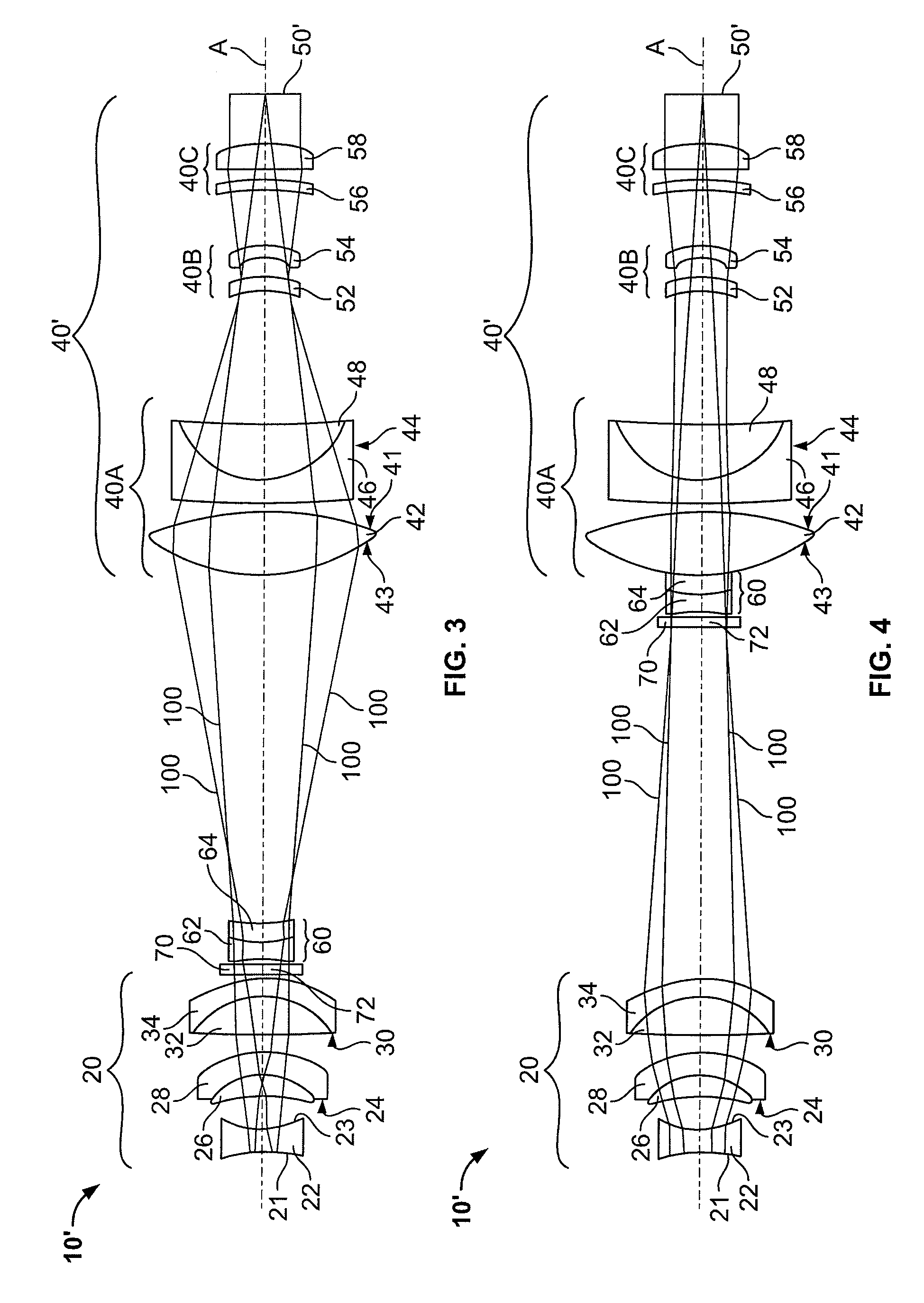

[0014]Referring to FIGS. 1 and 2, an exemplary dual field of view zoom lens system 10 is shown. In the example shown, the system 10 generally has a first lens group 20, a second lens group 60, a third lens group 40, and an optical stop 70. As is well known in the art, each lens “group” can consist of a single lens or can be made up of multiple lenses, depending on the usage and requirements of the system.

[0015]First and third lens groups 20, 40 are aligned along an optical axis A and their positions relative to each other and to focal plane 50 are fixed. Second lens group 60 is aligned along optical axis A between first lens group 20 and third lens group 40 and is movable linearly between a first position (shown in FIG. 1) and a second position (shown in FIG. 2), for example through a linear drive screw, a worm-gear device with a stepper motor, or any other well know device for providing linear motion to a lens group. Optical stop 70 is connected to second lens group 60 such that op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com