Non-symmetrical wire clip for clotheslines

a wire clip and clothesline technology, applied in the field of clothesline clips, can solve the problems of reducing the air flow between the garments, affecting the appearance of the clothesline, so as to improve the arrangement of the laundry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

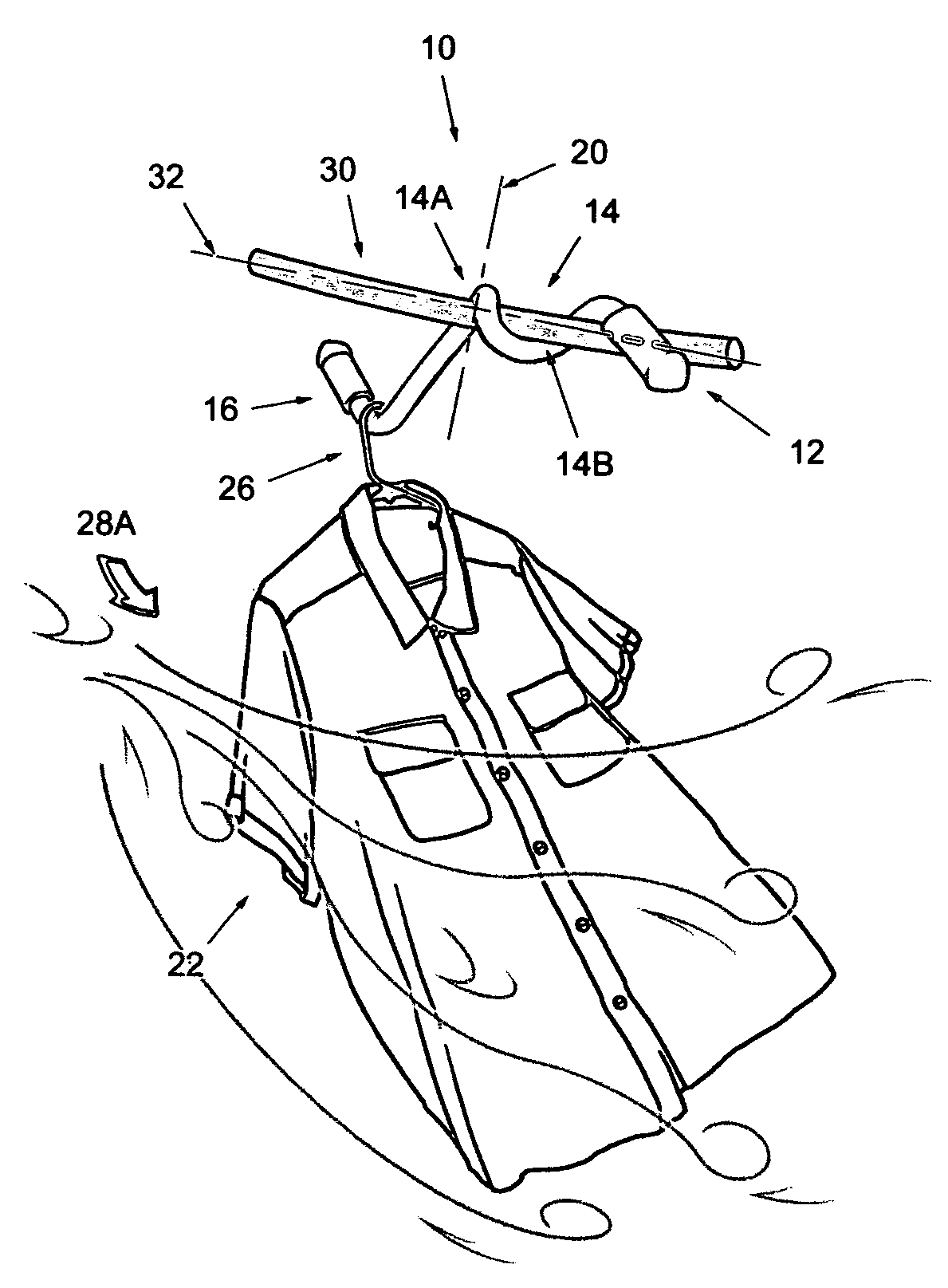

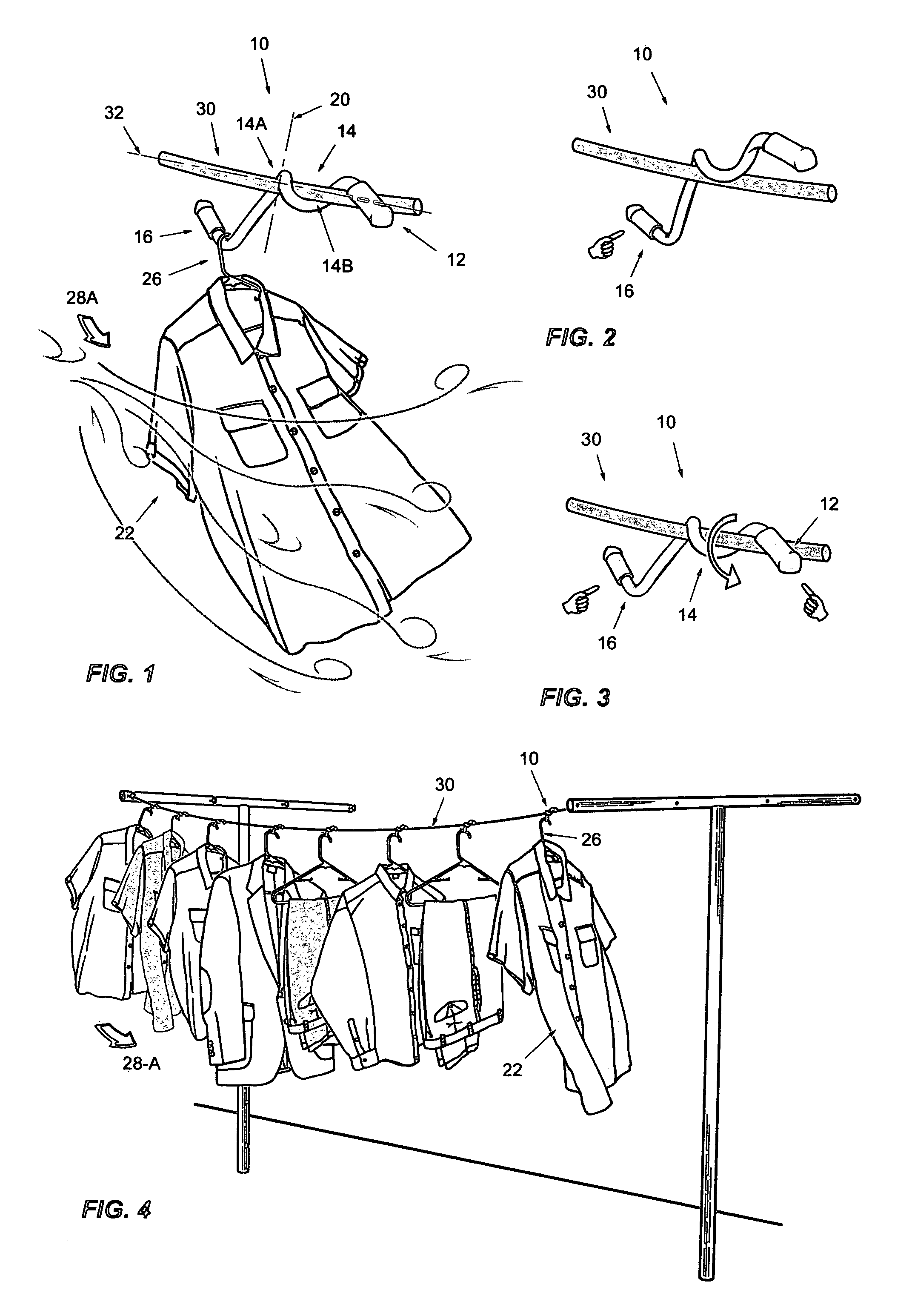

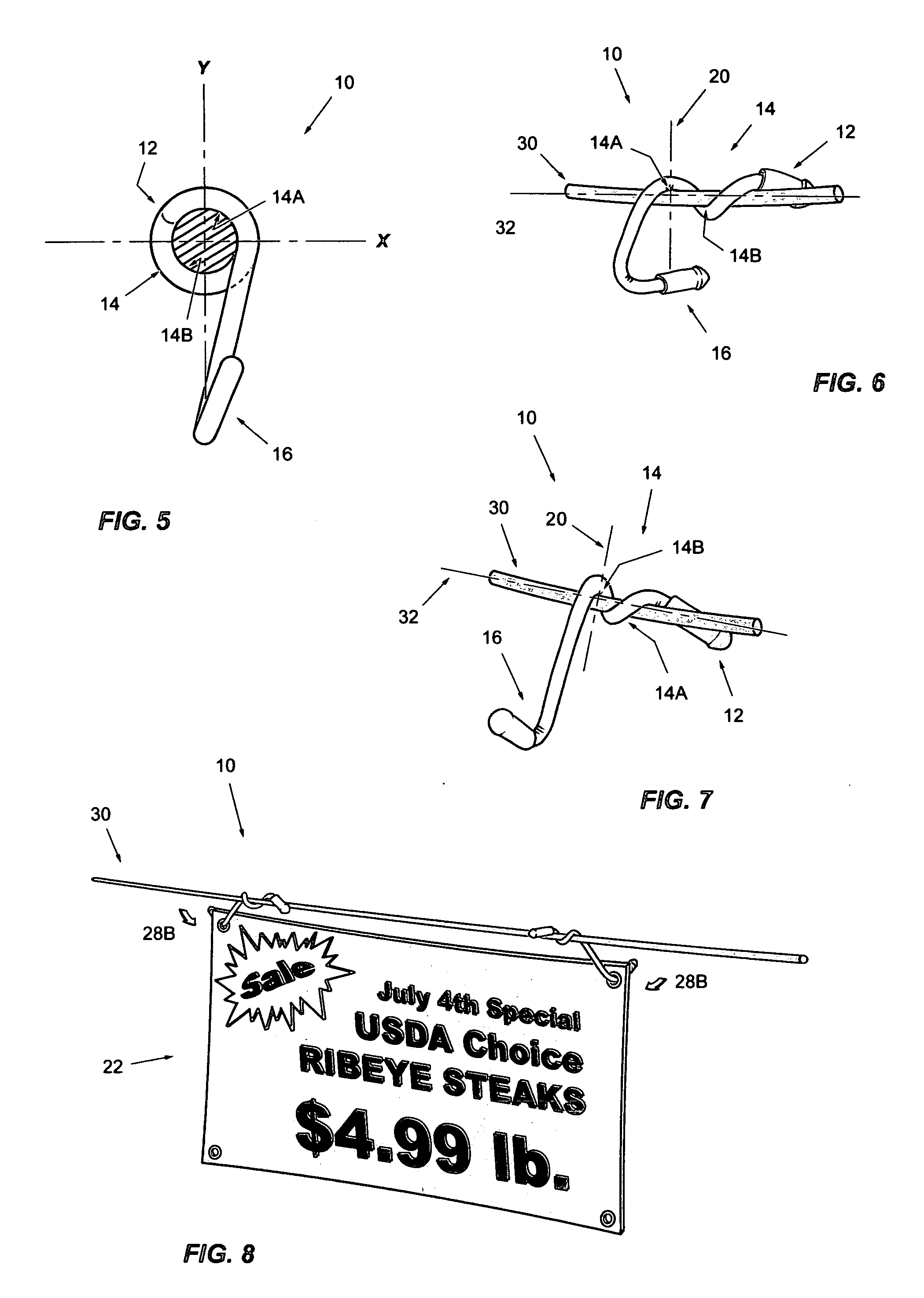

[0038]FIG. 1 shows the invention, an improved wire clip 10 offering a non-symmetrically centered axis 20 perpendicular to the clothesline 30 and its axis 32. A friction body 14 provides a pressure means by a fulcrum locus 14-A opposing a counter locus 14-B. A catch tail 16 is provided for the suspended garment 22.

[0039]The weight of the suspended garment 22 from the catch 16 leverages the friction body 14 at the non-symmetrical axis 20 which disposes the fulcrum locus 14-A, and opposes the counter locus 14-B to create the increased pressure onto the line 30.

[0040]The clip 10 now provides a non-symmetrical 20 friction pressure means 14 and catch 16 to better keep the hung laundry separated onto clotheslines. The pressure applied by the loci 14-A and 14-B is increased by additional biasing means 28 such as windy conditions 28-A.

[0041]The clip 10 is formed by a one-piece wire or molded configuration having only three main sections: a clutch head 12; a friction body 14; and a catch tail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com