Methods and devices for moving trench grates

a trench grates and trench technology, applied in the direction of roof drainage, hoisting equipment, water-power plants, etc., can solve the problems of stepping into the opening, dragging the movers, and dragging the movers, so as to reduce the load required, reduce the load, and facilitate the movement of the trench grates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

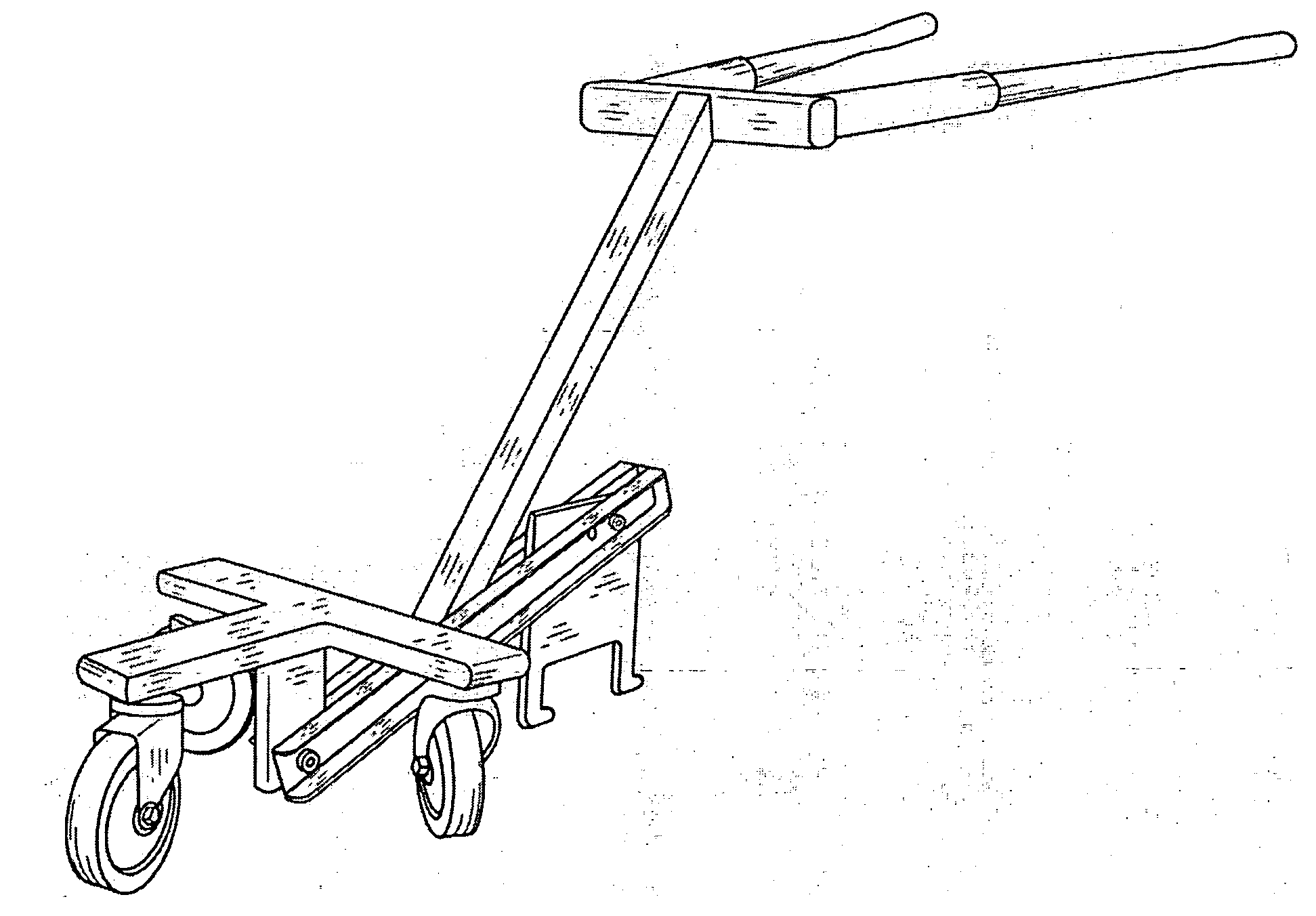

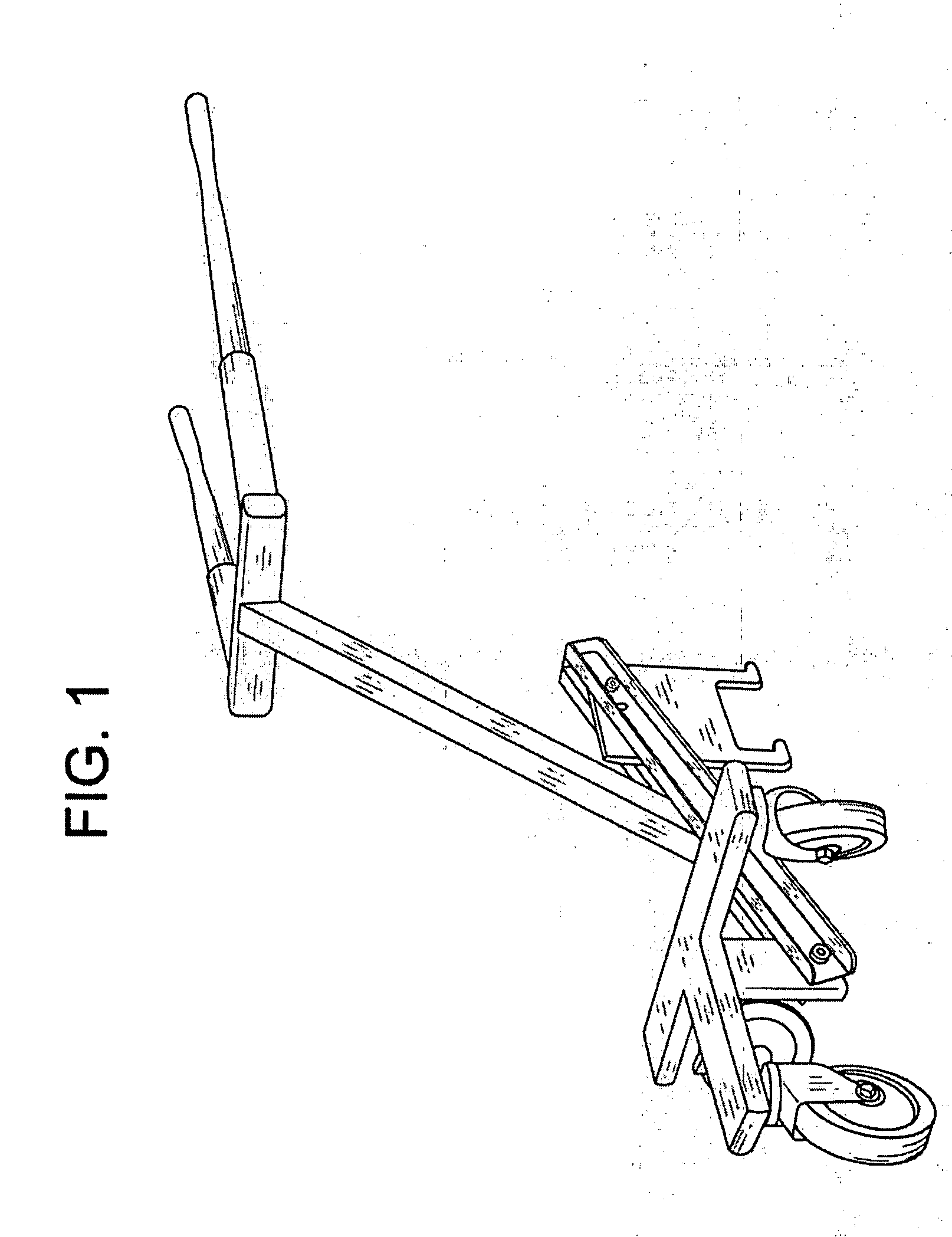

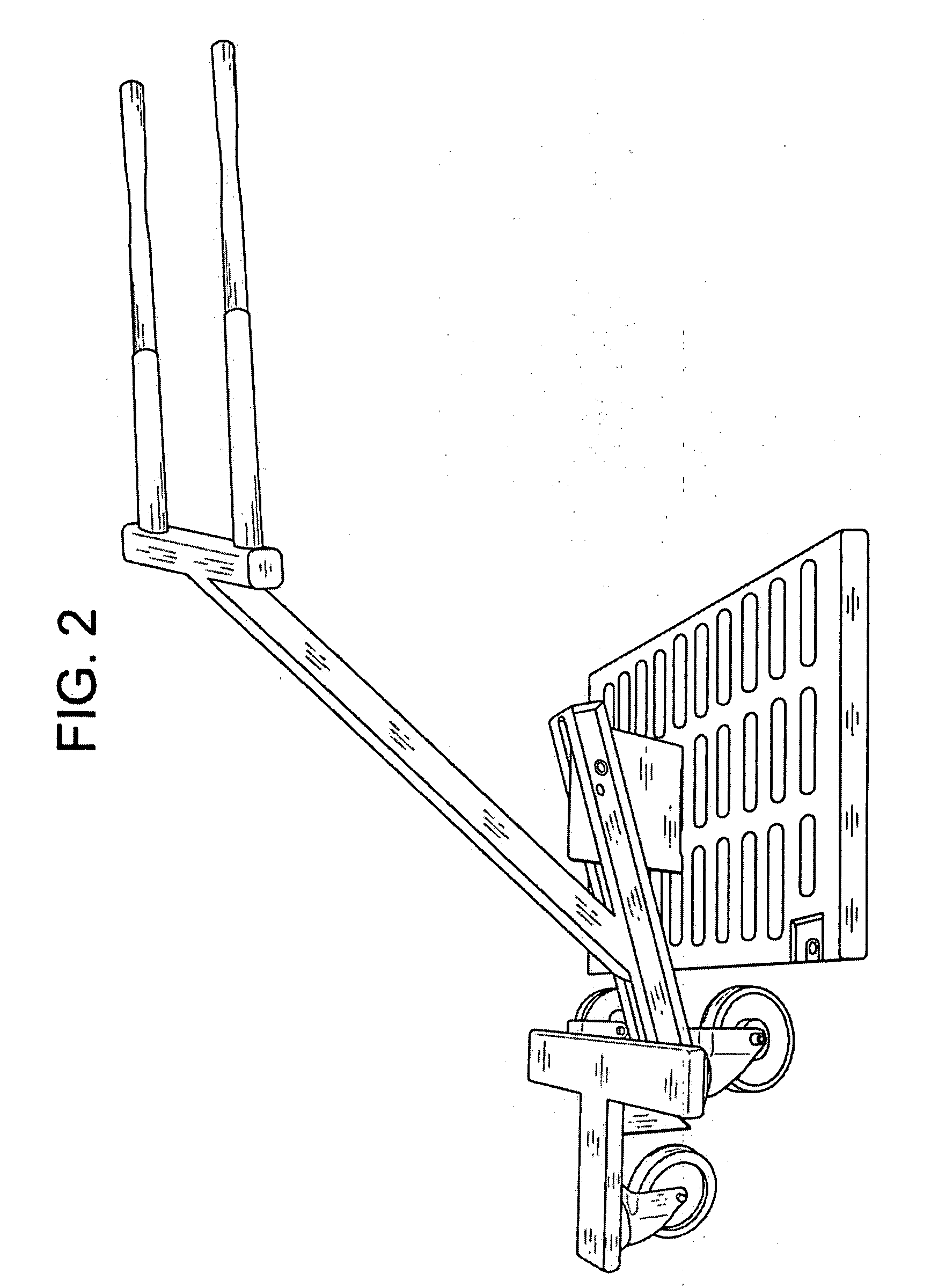

[0010] Referring to FIG. 1, there is shown a picture of a device 1 for moving a trench grate according to one embodiment of the present invention.

[0011] A shown, the device 1 includes a pair of handles 3,4 extending from a frame 5, which is suspended from a mid-point 6 in a three swivel wheeled, lower frame arrangement 7 (e.g., dolly). This suspension allows the handle frame 5 to be raised, and lowered, while still maintaining three wheel contact with the floor. This allows the plurality of wheels 8 on the lower section of the frame to swivel freely, regardless of the handle elevation.

[0012]FIG. 1 also depicts a dual-contact hook 9 hanging from the frame 5, at an approximated one third distance between a physical point of contact on a handle, and a suspension point (on the lower frame or dolly). This hook 9 is designed to fit within a specific grate (i.e., grate pattern) so as to ensure contact at two points (for stability). As the reader will surmise, because of this the hook 9 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com