Mattress Comprising An Active Heat Absorbing/Releasing Layer In Combination With A Down Layer

a technology of active heat absorption and release layer, applied in the field of mattresses, can solve the problems of person waking up later on freezing, mattress dampness, sweat, etc., and achieve the effect of improving the functionality of the temperature regulating material and minimizing the moisture from both sides of the mattress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

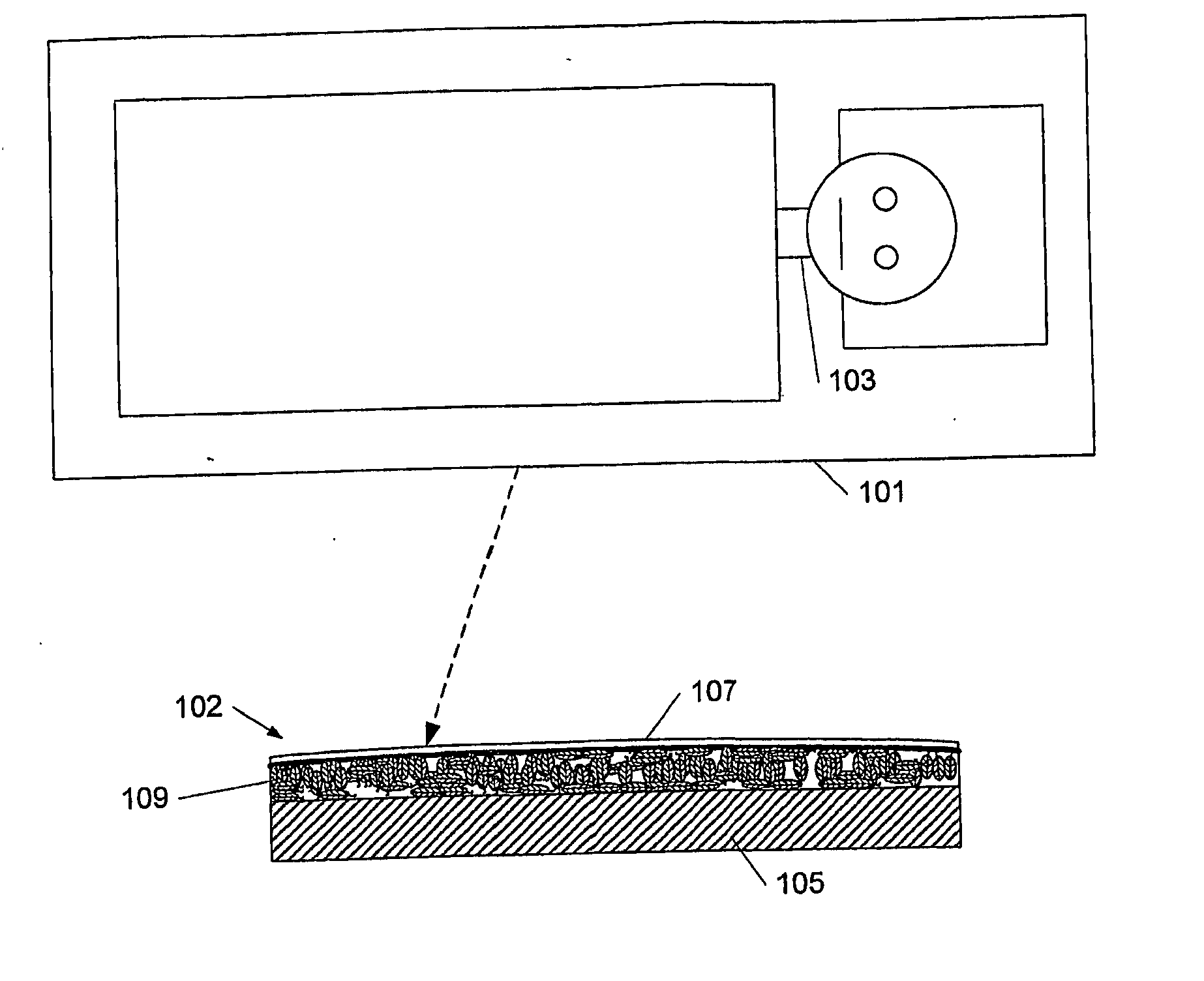

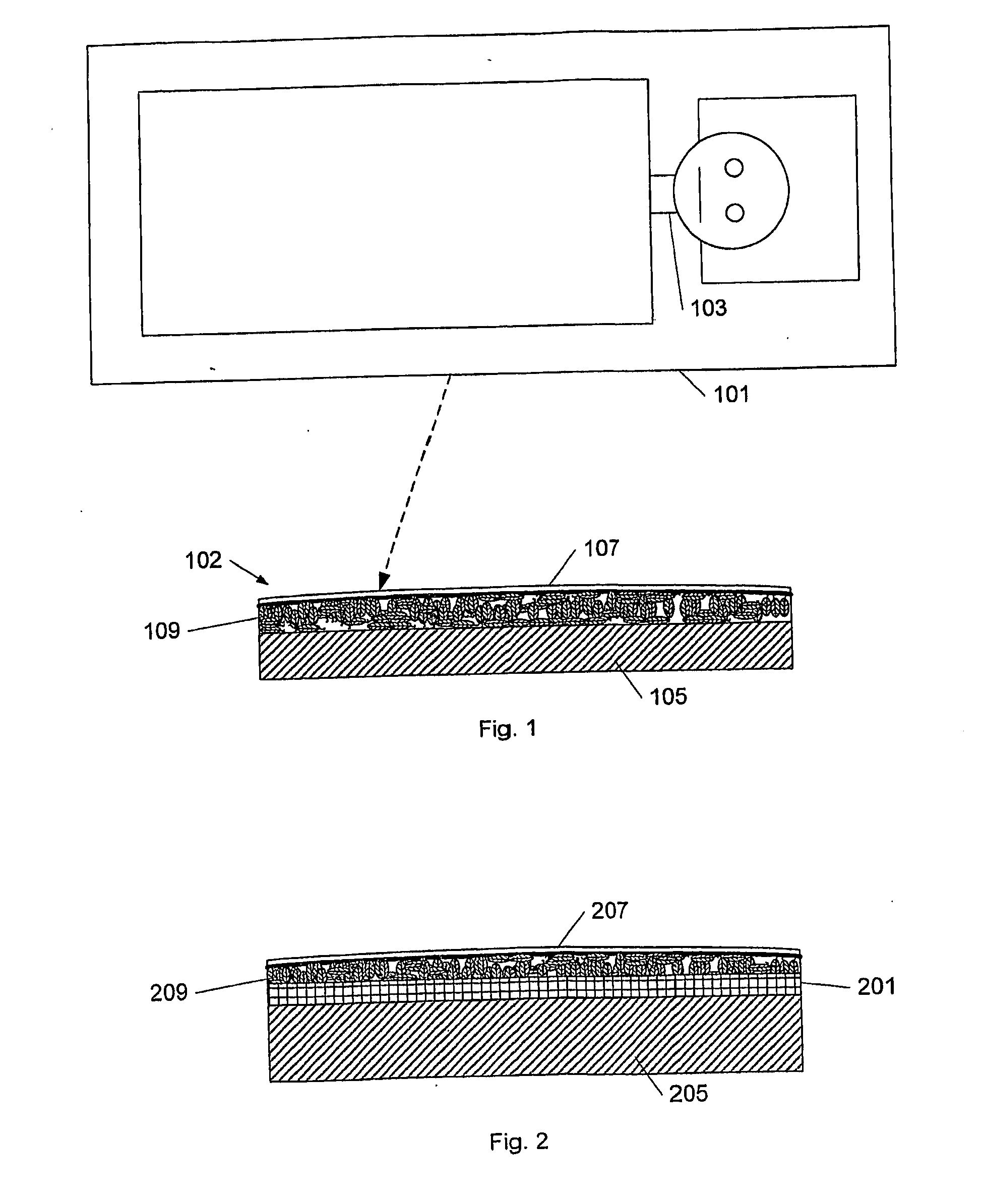

[0031]FIG. 1 illustrates a mattress according to the present invention. The mattress 101 is in contact with a large part of the human body 103 during sleep. A cross section of the mattress 101 is illustrated at 102. The mattress comprises a support element 105 e.g. a core based on foam and / or springs, wherein the support element is covered by a first layer of a material having temperature regulating properties such as phase change material 107 and a second layer of down 109

[0032] The layer of down between the support element and the phase change material could in one embodiment be manufactured by sewing a top layer comprising the layer of temperature regulating material 107 with separating wall generating channels. Thereafter the down filling is blown into the channels and when filled, the channels are closed.

[0033] As an alternative a top mattress to be placed on top of an existing spring based mattress could comprise the second layer of down filling and the first layer of tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com