Rotary tablet press

a tablet press and rotary technology, applied in the direction of shaping presses, ceramic shaping apparatuses, manufacturing tools, etc., to achieve the effect of not exposing the user to dust leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

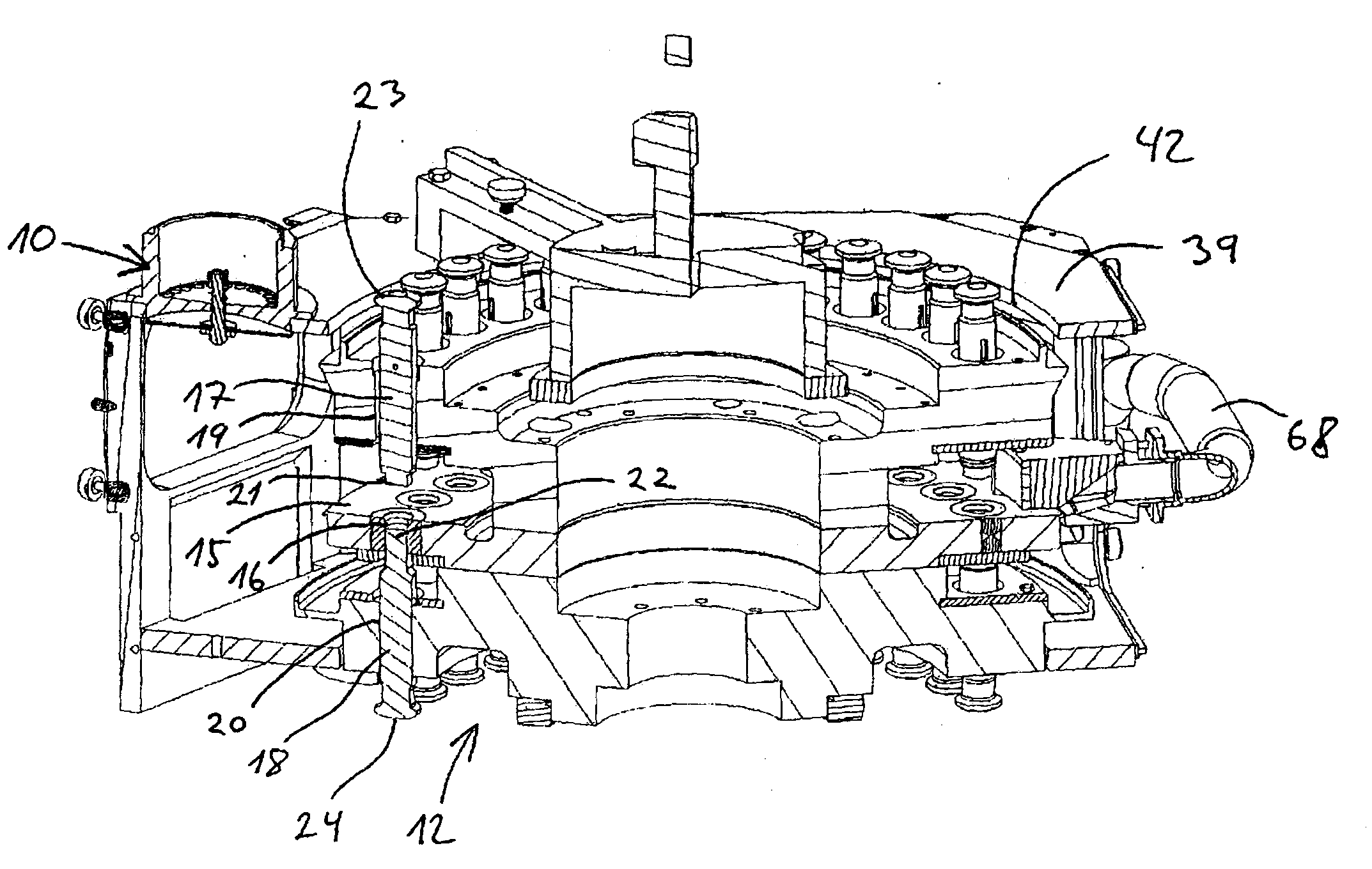

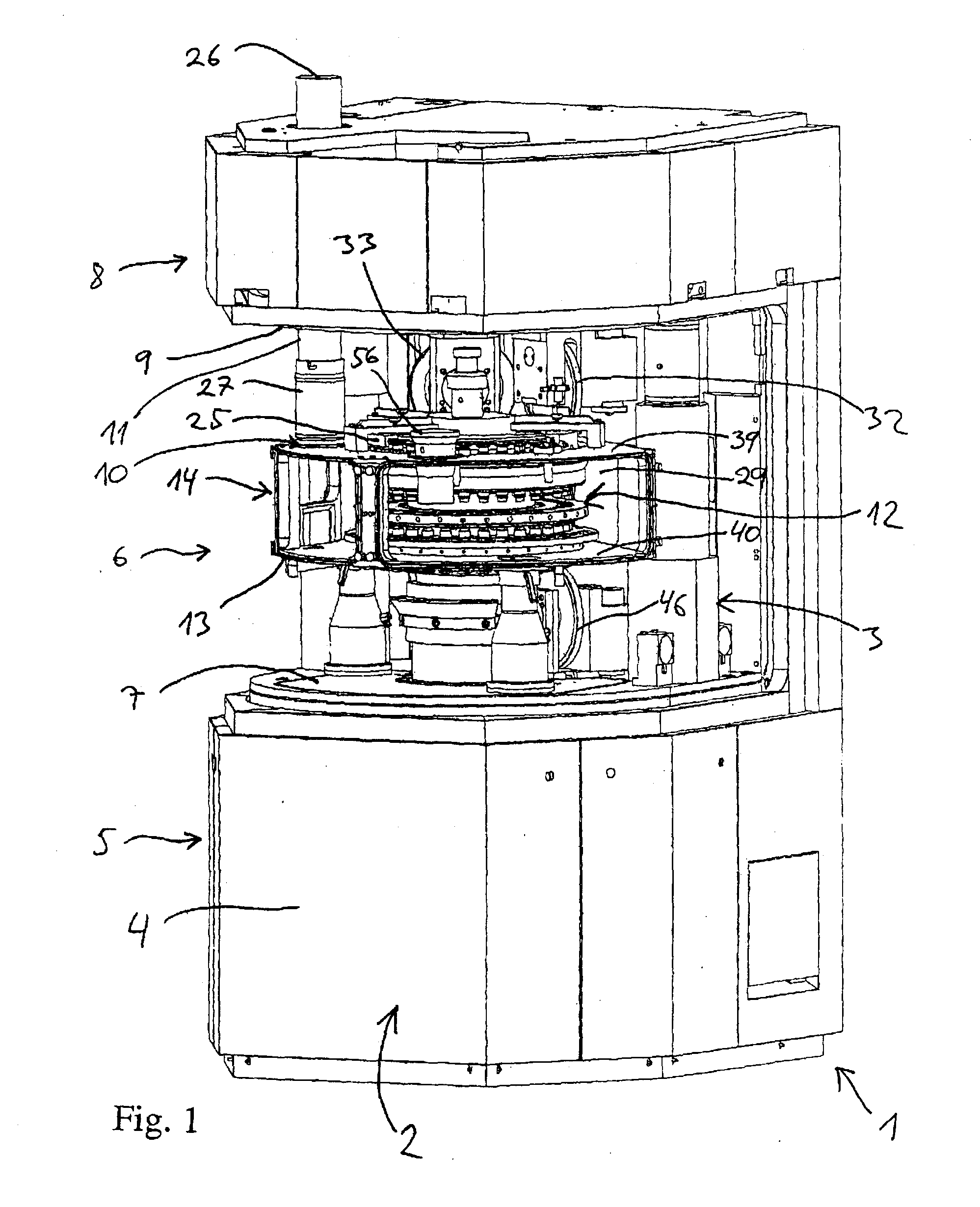

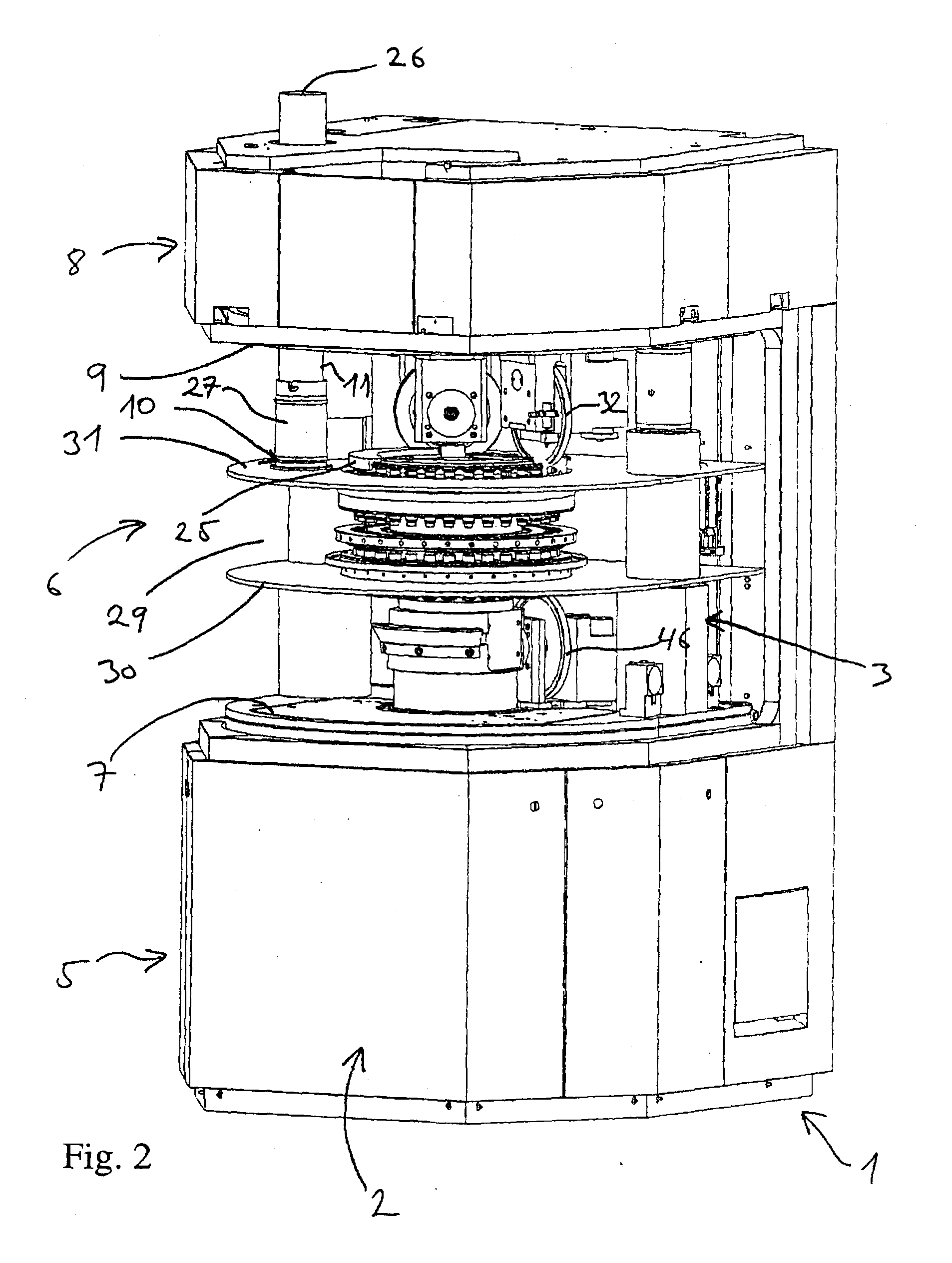

[0040]FIG. 1 shows a rotary tablet press 1 for compression of a feedstock in the form of powder or granular material into tablets, compacts or the like. The press shown is of a type suitable for use in the pharmaceutical industry, but the press according to the invention may as well be a so-called industrial press employed in the production of a variety of different products, such as vitamins, pet food, detergents, explosives, ceramics, batteries, balls, bearings, nuclear fuels, etc.

[0041]The rotary tablet press 1 has a press housing 2 comprising an internal frame 3, which supports various components located in the housing 2, and an outer lining 4, which is shown only at a lower section 5 of the press. The press housing 2 is composed of three sections, which are located on top of each other and are separated by means of partition walls. The lower section, designated the drive section 5, is separated from a central section, designated the compression section 6, by a lower partition w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com