Method Of Manufacturing Applicator For Cosmetics And Applicator Cosmetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

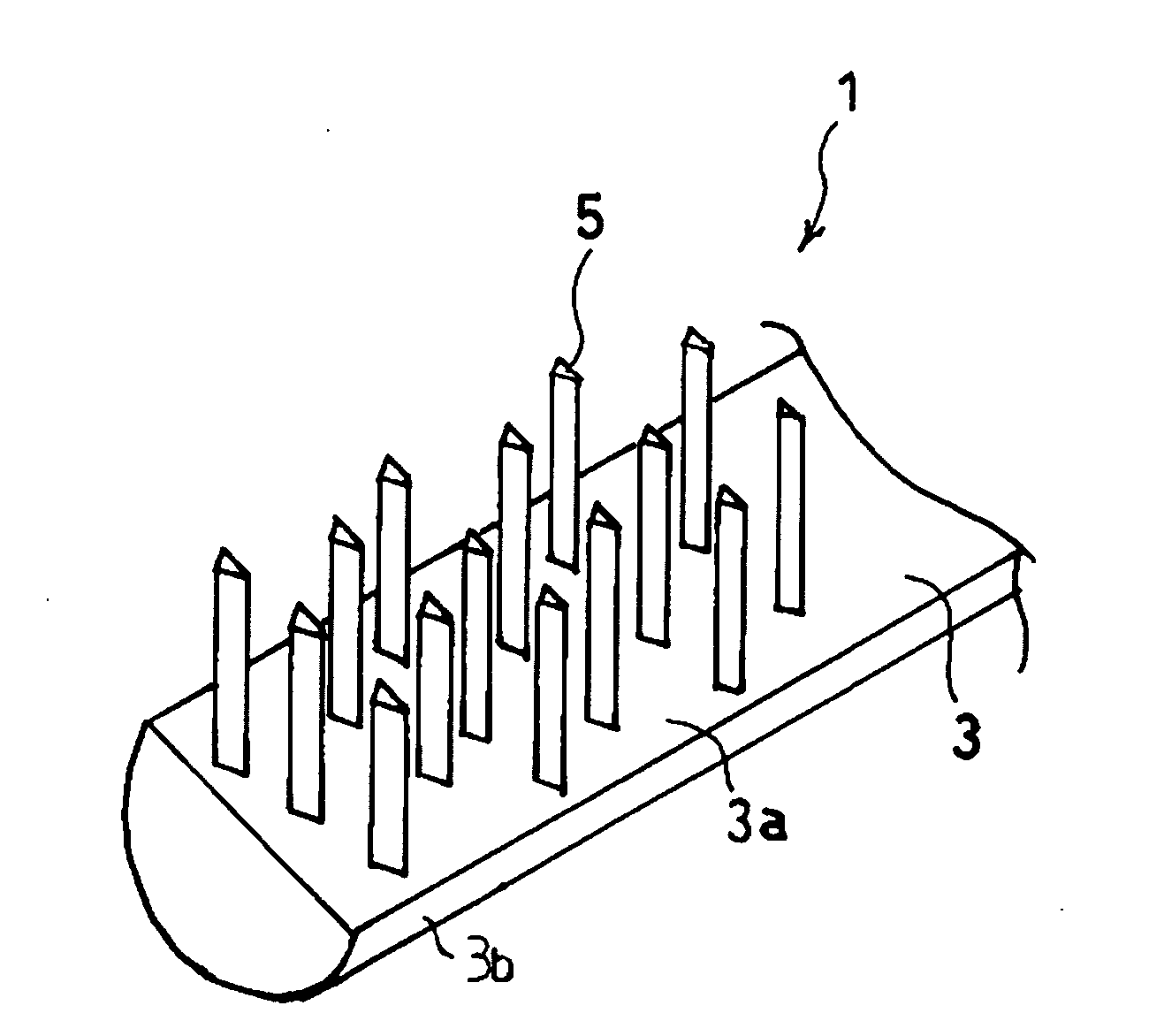

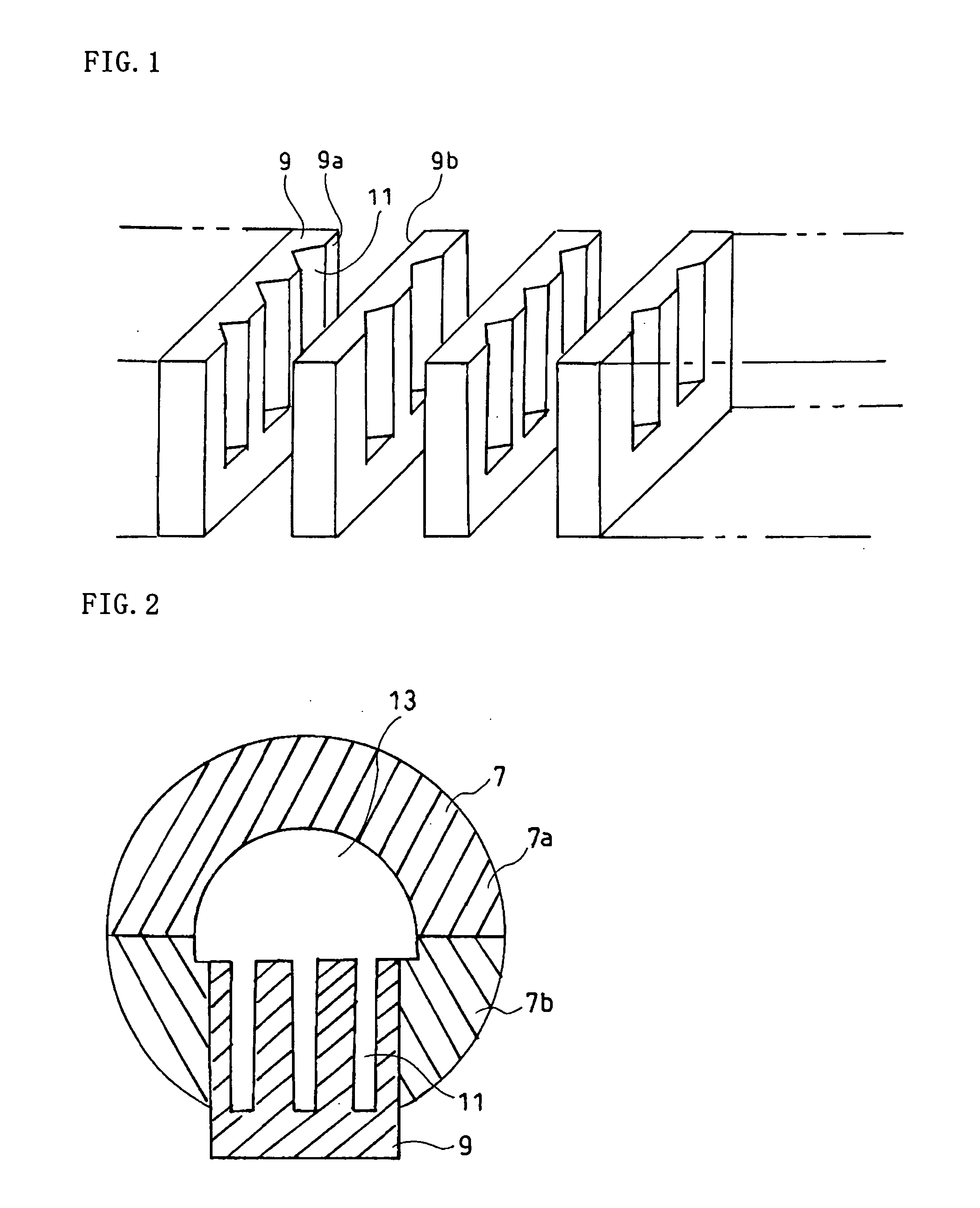

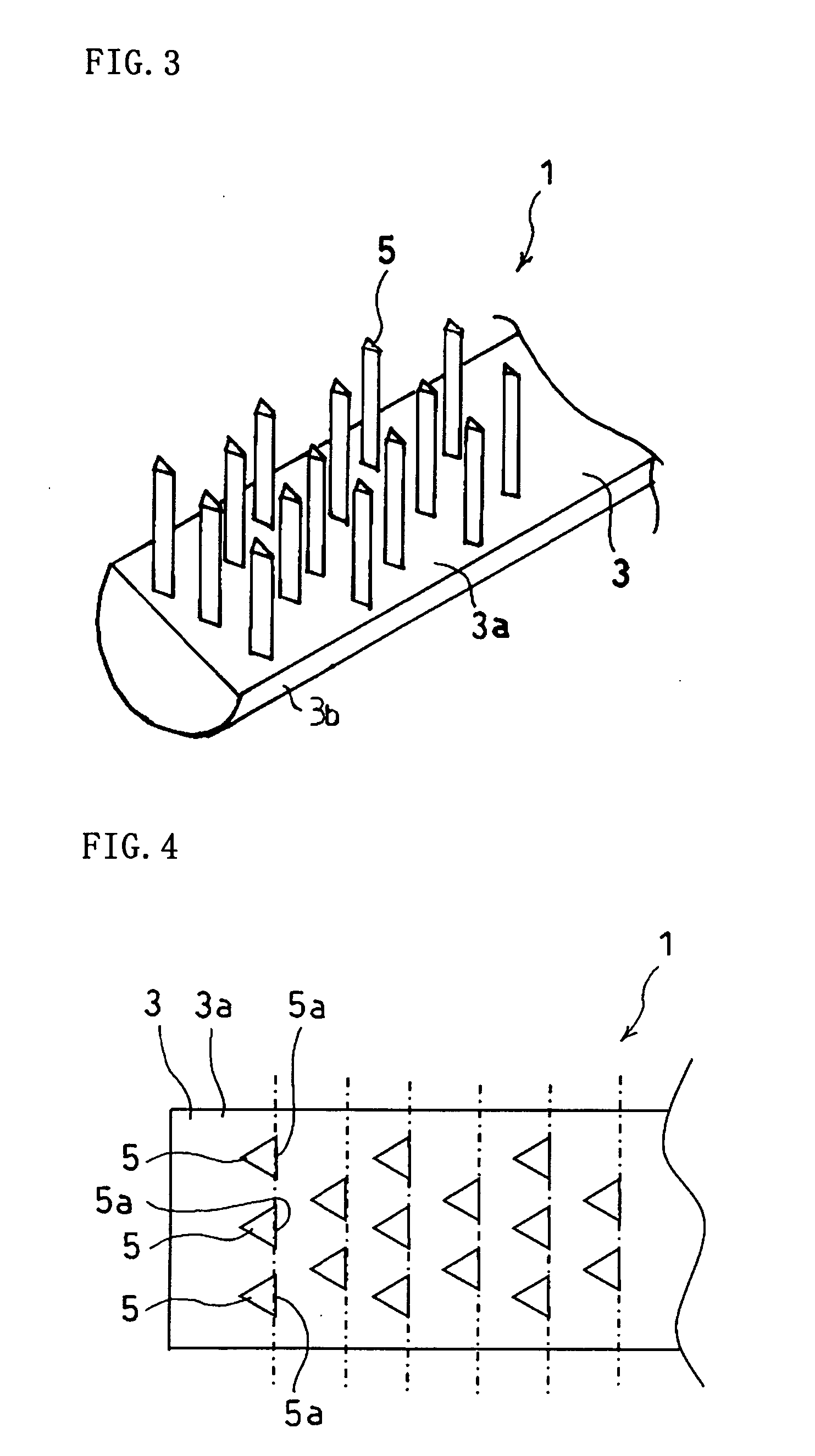

[0024] The following will specifically explain embodiments of the present invention with reference to the accompanying drawings. FIG. 1 is a perspective view illustrating essential parts of a mold for an applicator for cosmetics according to a first embodiment of the present invention; FIG. 2 is a cross-sectional view illustrating the mold for the applicator for cosmetics; FIG. 3 is a perspective view illustrating essential parts of the mold for the applicator for cosmetics according to the first embodiment of the present invention; and FIG. 4 is a plane view illustrating essential parts of the mold for the applicator for cosmetics according to the first embodiment of the present invention, respectively.

[0025] An applicator 1 for cosmetics according to an embodiment of the present invention is mainly used as a mascara brush and includes a shank 3, brush bristles 5 molded integrally with the shank 3.

[0026] The shank 3 has a flat surface 3a on which the brush bristles 5 are formed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com