Passive throttling valve outside of muffler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

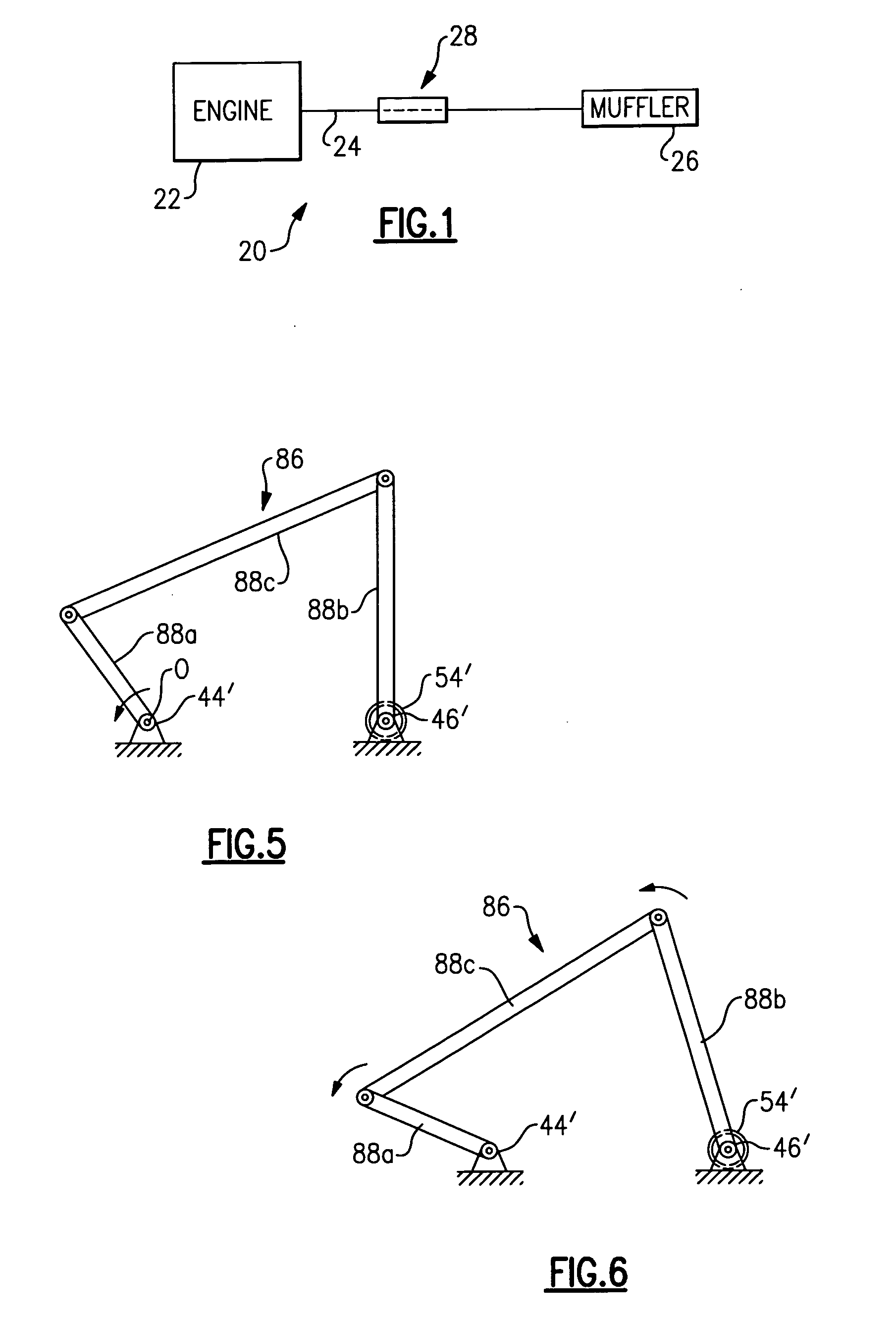

[0015]FIG. 1 schematically illustrates selected portions of an example exhaust system 20. In this example, the exhaust system 20 includes an engine 22, such as a gas combustion engine for use in a vehicle. The engine 22 is connected to one or more exhaust tubes 24 for conveying hot exhaust gases from the engine 22 to a muffler 26. A noise attenuation device 28 is associated with the exhaust tube 24 for reducing sound carried by the exhaust gases. Although, the illustrated example includes the muffler 26, the noise attenuation device 28 can be used without the muffler 26, or instead of the muffler 26.

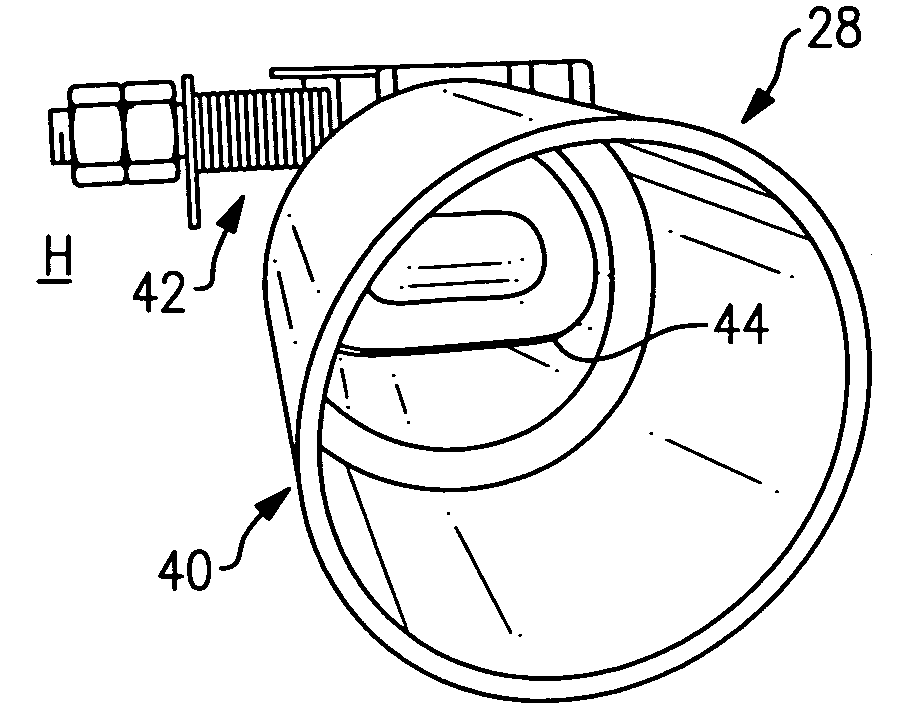

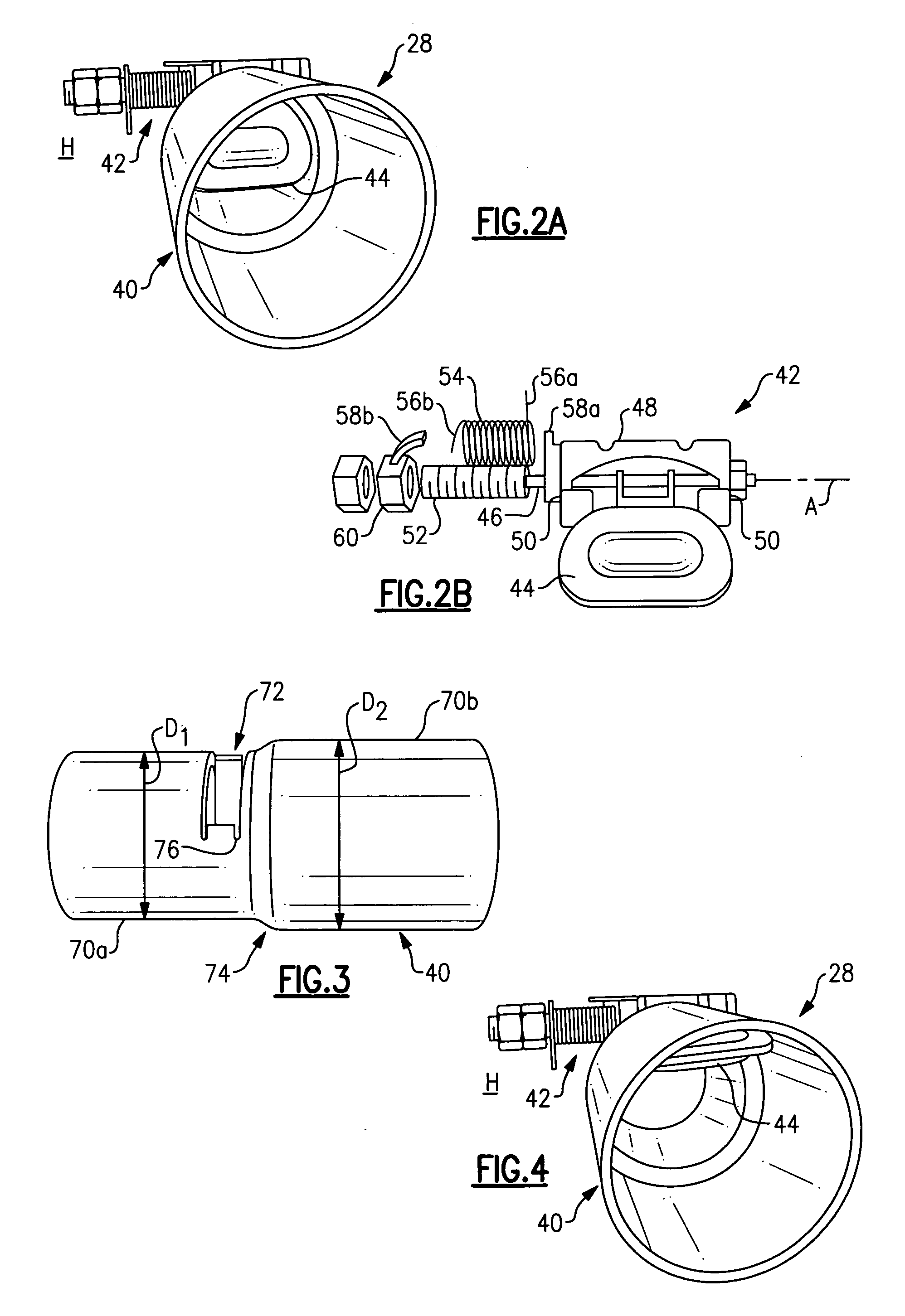

[0016]FIG. 2A illustrates a perspective view of one example noise attenuation device 28. In this example, the noise attenuation device 28 includes an exhaust tube section 40 connected to the exhaust tube 24 from the engine 22 for conveying the heated exhaust gases. A valve 42 is disposed at least partially within the exhaust tube section 40 to attenuate noise carried by the exhaust gases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com