Vacuum adsorbing apparatus for fan positioning

a technology of vacuum adsorption and fan positioning, which is applied in the direction of non-positive displacement fluid engines, pump components, reaction engines, etc., can solve the problems of reducing the pre-operation time of fan molding, reducing the effectiveness of fixing, and wasting all previous efforts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

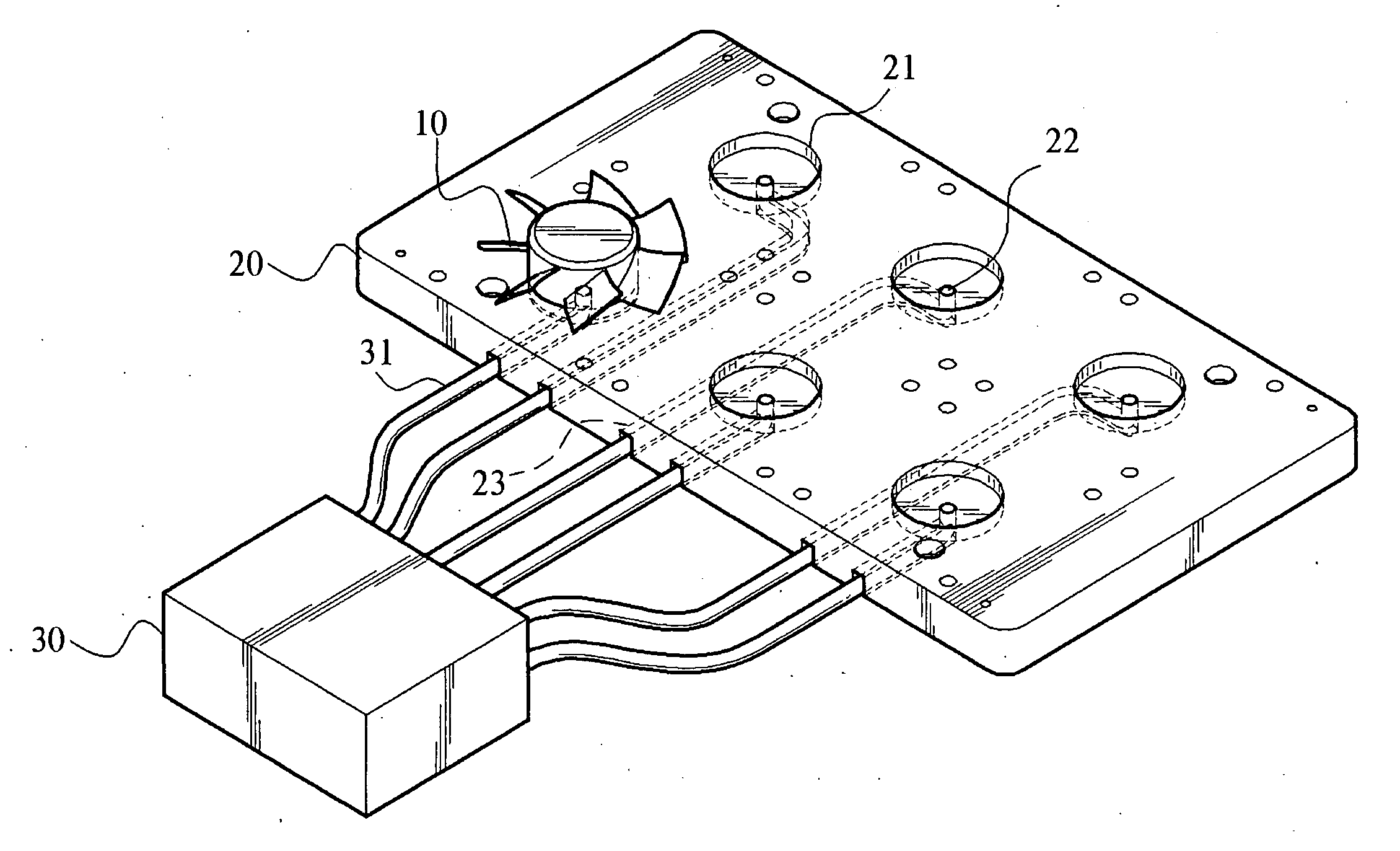

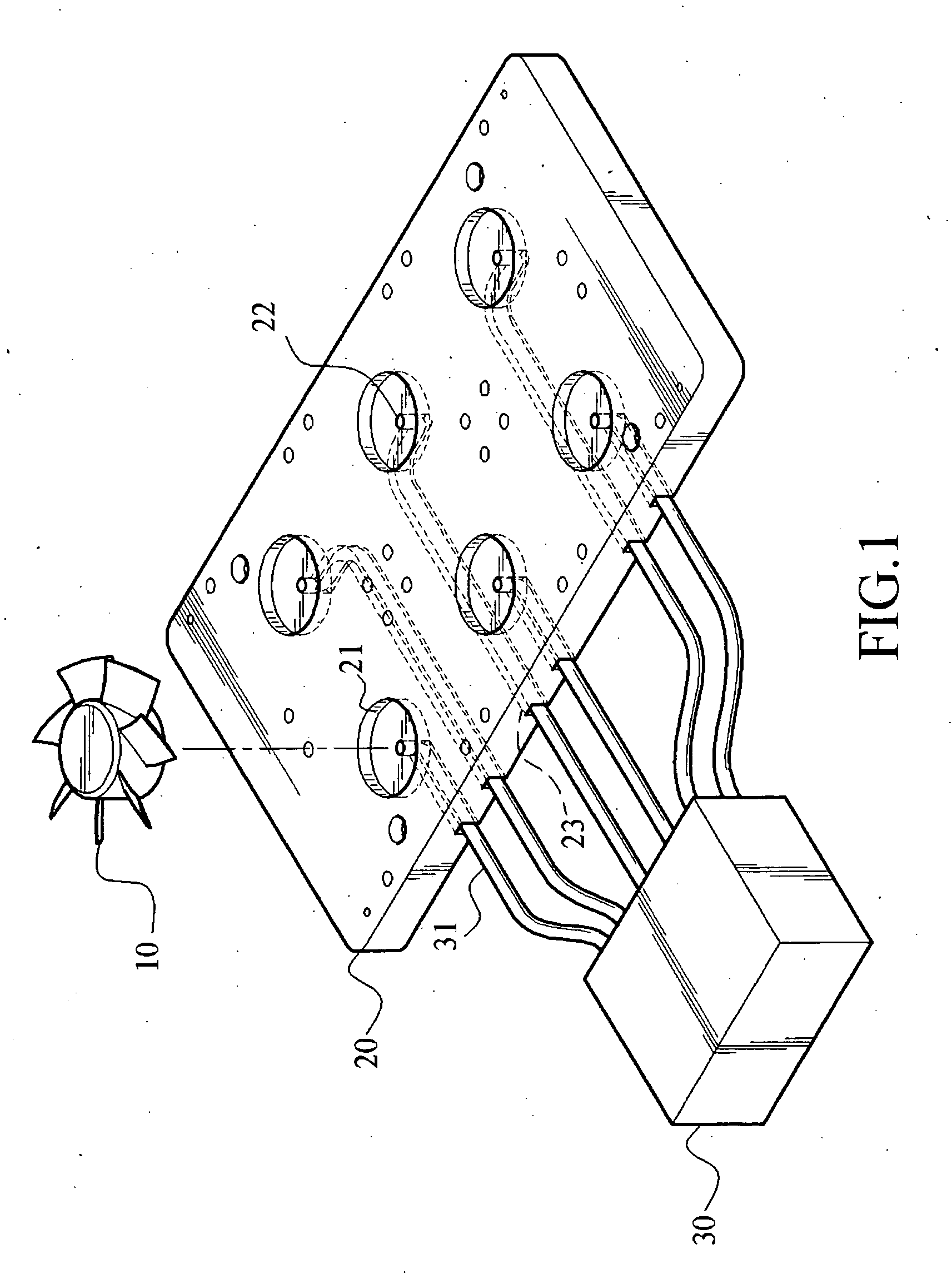

[0018]As shown in FIG. 1, it is a basic architectural schematic view of the present invention, which includes at least one fan 10, a fixing frame 20, and a vacuum aspirator 30. The fixing frame 20 has a plurality of workpiece holders 21 thereon, and the fan 10 may be arranged in any one of the workpiece holders 21. The workpiece holders 21 are each provided with a through-hole 22 in its center, and the fan 10 may form a closed space with the through-hole 22 when placed onto the workpiece holder 21. The fixing frame 20 is provided with a plurality of air flues 23 in communication with corresponding through-holes 22. The vacuum aspirator 30 has a plurality of air pipes 31 connected to the through-holes 22 via the air flues 23. And the through-hole 22 is further provided with a thread (not shown) for the air pipe 31 to be screwed thus forming a state of being closely connected.

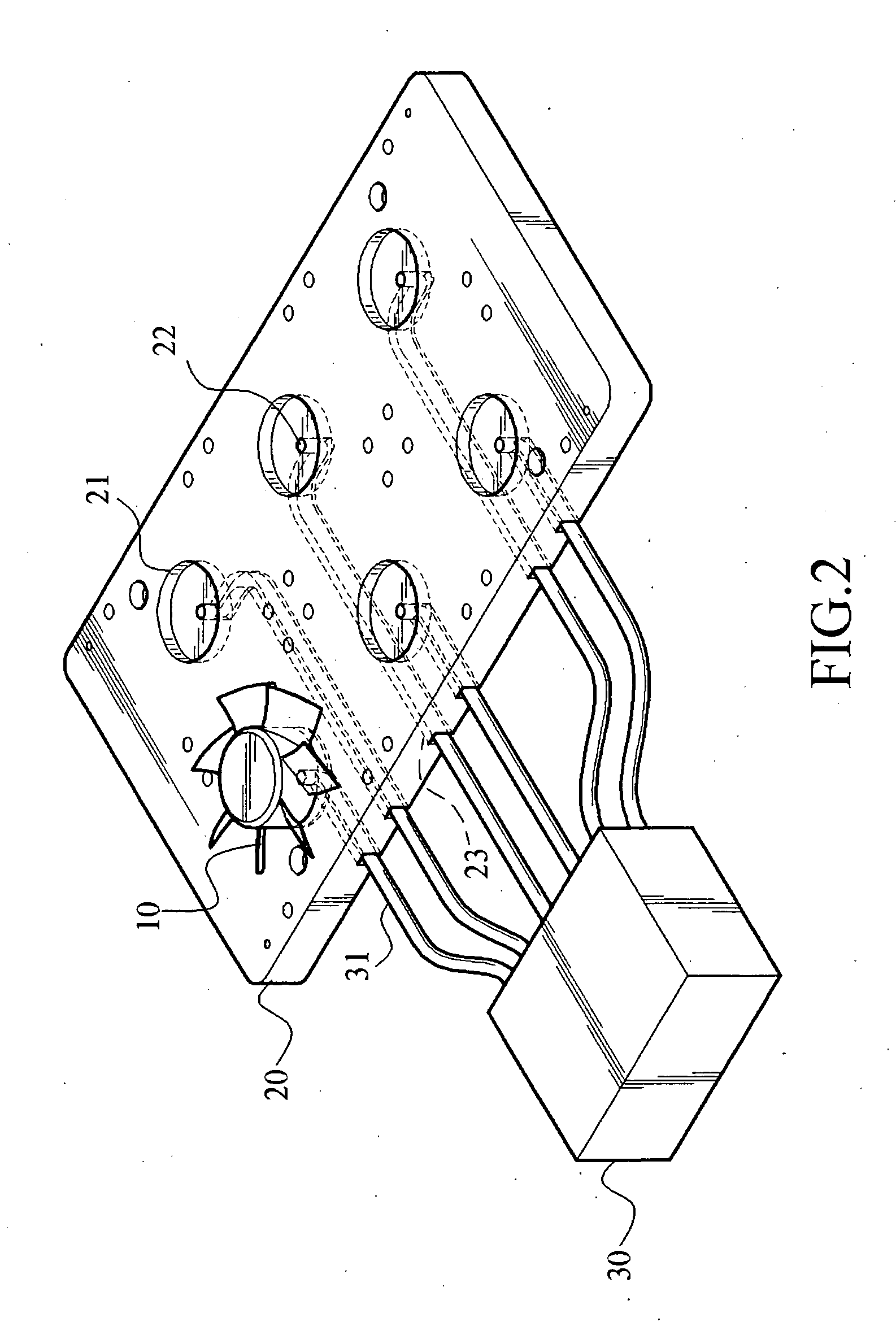

[0019]As shown in FIG. 2, it is a schematic view showing that the fan 10 is fixed to the fixing frame 20. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com