Polishing pad and chemical mechanical polishing apparatus comprising the same

a technology of mechanical polishing and polishing pad, which is applied in the direction of grinding machine, manufacturing tools, lapping machines, etc., can solve the problems of variation in the rate at which material is removed across the surface, difficult to planarize a semiconductor substrate sufficiently, and non-uniform distribution of slurry across the surface of the polishing pad. to achieve the effect of enhancing the uniformity of the ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

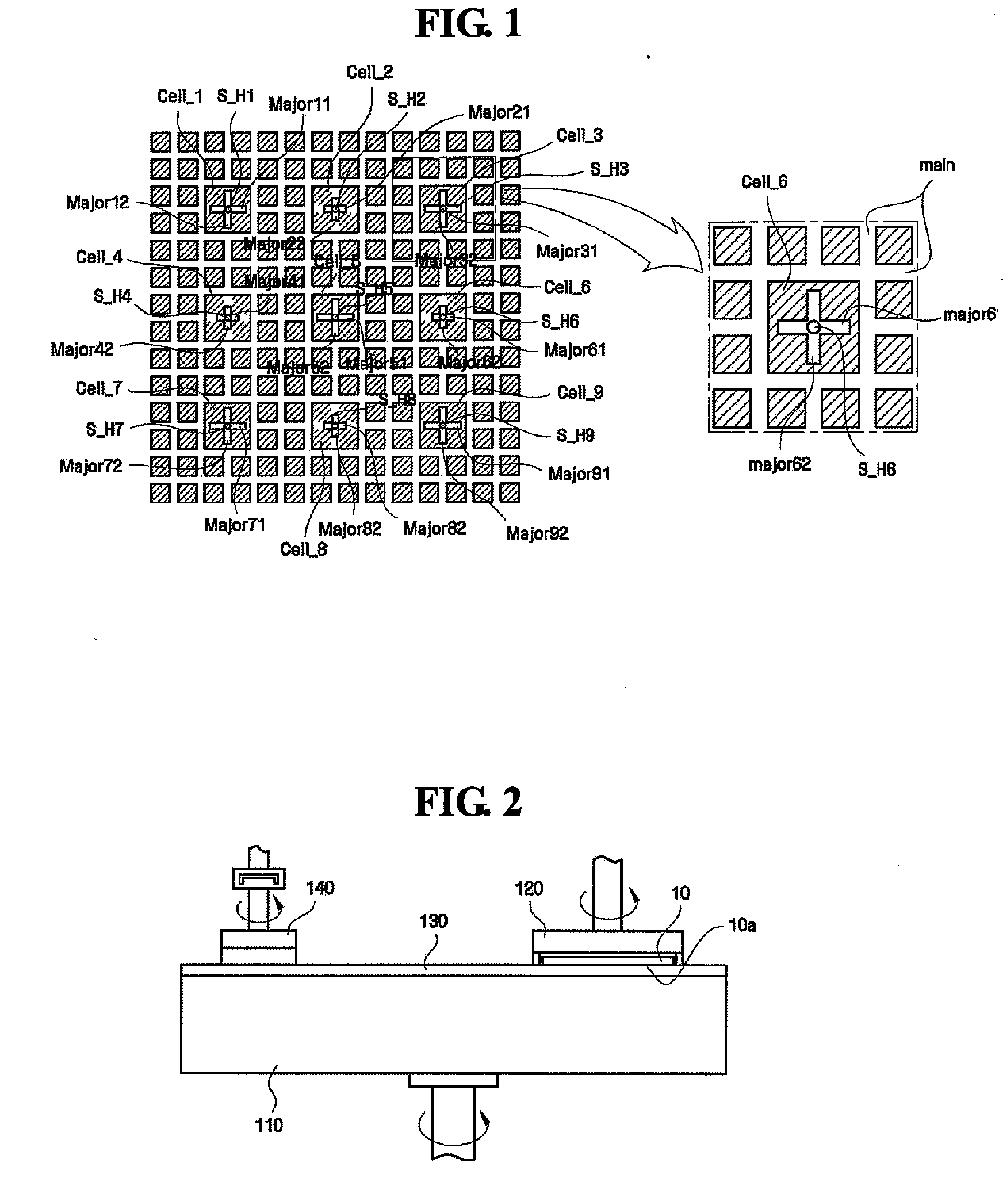

[0025] the polishing pad of the CMP apparatus according to the present invention will now be described with reference to FIG. 3.

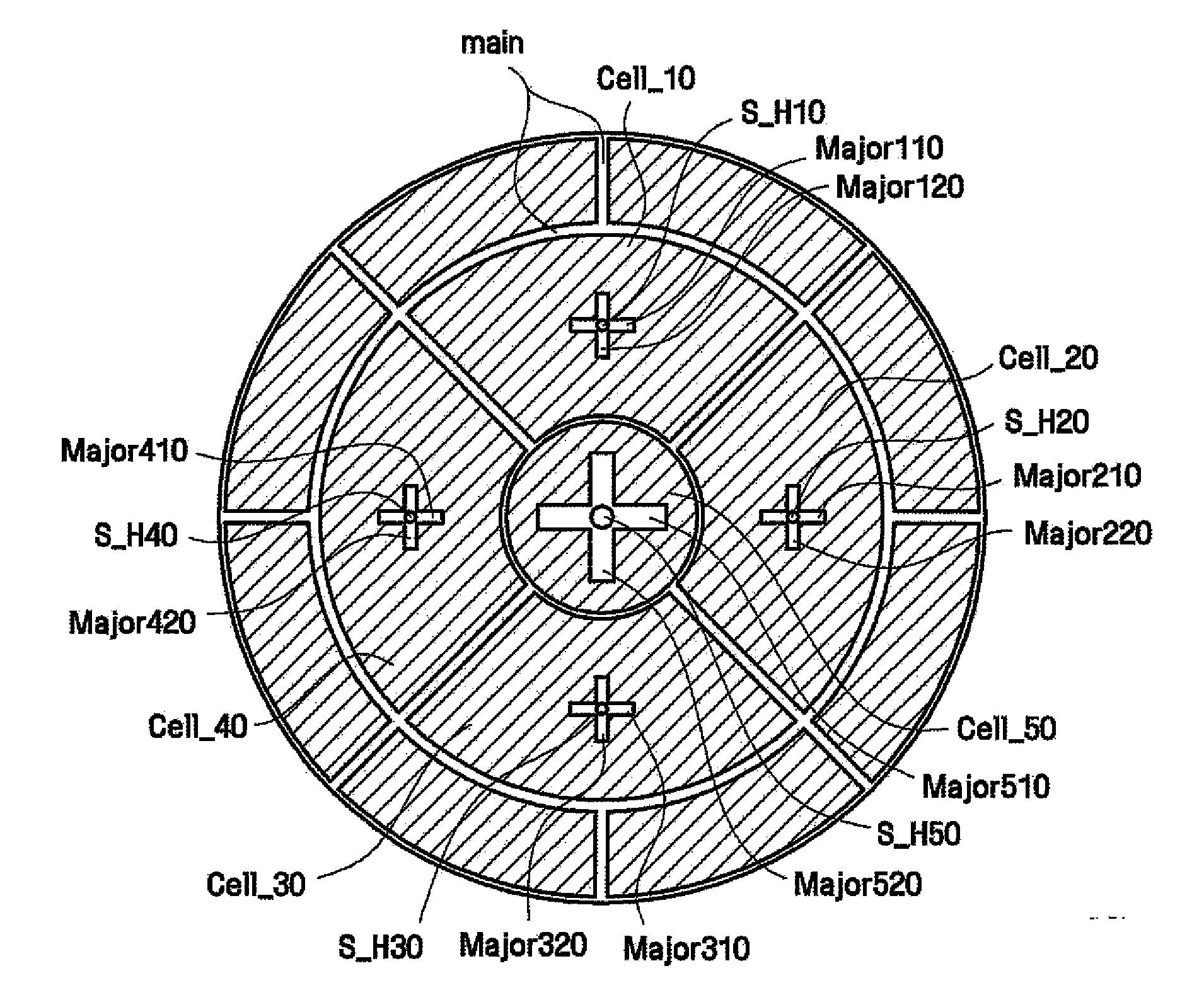

[0026] The polishing pad has an upper portion divided into a plurality of cells Cell_1 through Cell_9 by main grooves. The cells Cell_1 through Cell_9 are square and are delimited by the main grooves which are thus seen to extend along the periphery of the cells Cell_through Cell_9. The cells Cell_1 through Cell_9 consist of land portions, and grooved portions defined by first major grooves Major11 through Major91, respectively. In addition, a system slurry holes S_H1 through S_H9 extend through the body of the pad, and one or more slurry holes S_H1 through S_H9 are open to the first major grooves Major11 through Major91. Slurry for polishing the target surface of an object (e.g., a semiconductor substrate) is supplied to the slurry holes S_H1 through S_H9 via a passageway in the platen of the CMP apparatus (170 in FIG. 2).

[0027] The first major grooves Ma...

second embodiment

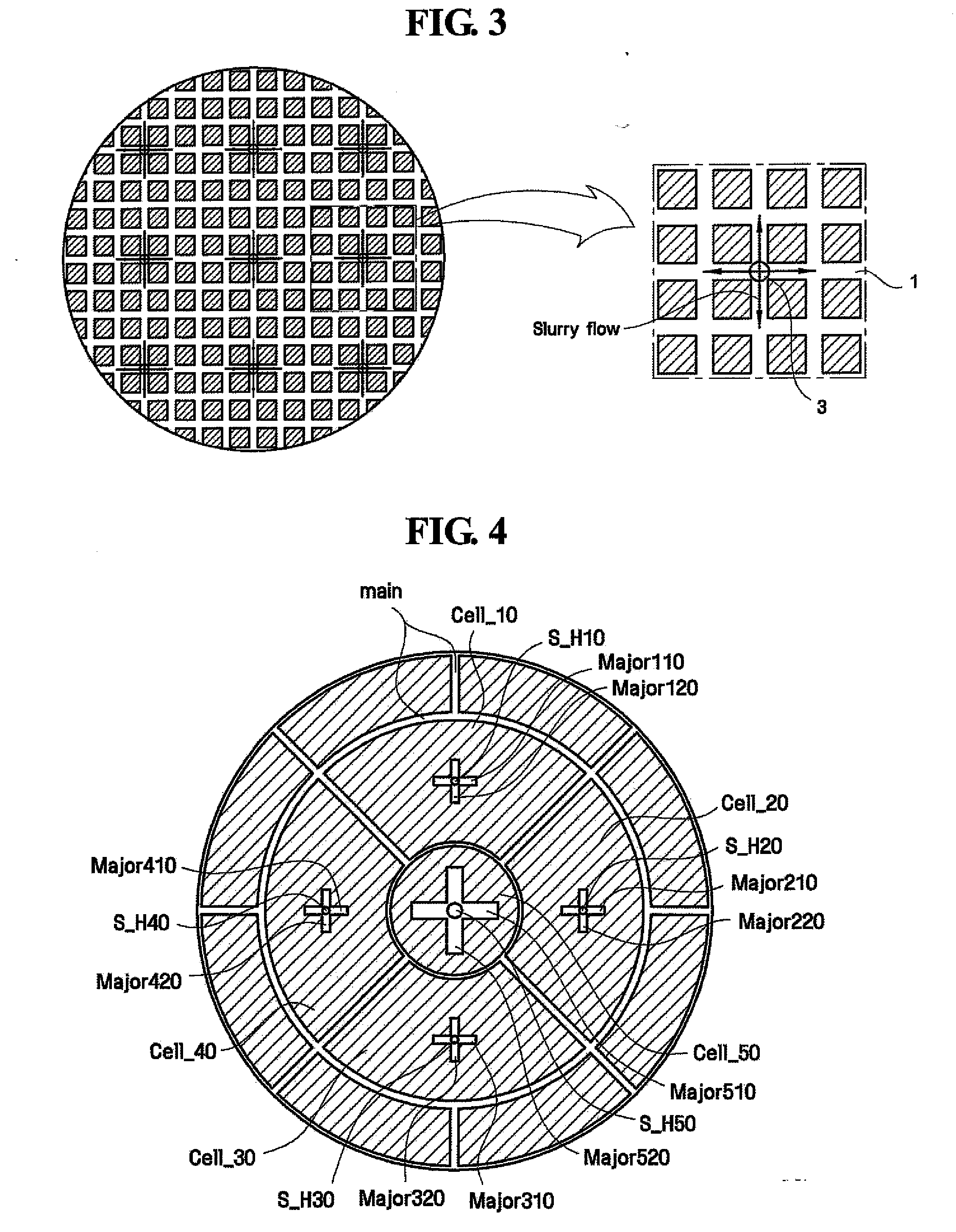

[0035] a polishing pad according to the present invention will now be described with reference to FIGS. 5 and 6.

[0036] The second embodiment of the polishing pad has a plurality of cells delimited by main grooves, and in this case, the grooved portion of a respective cell is defined by major and minor grooves. In addition, slurry holes extend through the body of the pad and are open to the major grooves within the cells, respectively. Even though this embodiment of the polishing pad may include nine cells arranged similarly to that shown in FIG. 3, only a sixth cell Cell_6 is illustrated in FIGS. 5 and 6 for the sake of simplicity. All of the cells have a structure similar to that of the sixth cell Cell_6 and therefore, only the structure of the polishing pad associated with this Cell_6 will be described in detail.

[0037] The cell Cell_6 is square. Main grooves extend within the upper surface of the pad to delimit the cell. Thus, main grooves are seen to extend along the periphery o...

third embodiment

[0043] a polishing pad of a CMP apparatus according to the present invention will now be described with reference to FIG. 7.

[0044] The third embodiment of the polishing pad has a plurality of cells, main grooves, and major and minor grooves extending within each of the cells. In addition, slurry holes extend through the body of the pad and are open to the upper surface of the pad within the cells, respectively. Even though this embodiment of the polishing pad may include nine cells arranged similarly to that shown in FIG. 3, only a sixth cell Cell_6 is illustrated in FIG. 7 for the sake of simplicity. All of the other cells have a structure similar to that of the sixth cell Cell_6 and therefore, only the structure of the polishing pad associated with this Cell_6 will be described in detail with reference to FIG. 7. Moreover, the third embodiment of the polishing pad is similar to that of the second embodiment of FIGS. 5 and 6 and thus, only that portion of the third embodiment which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com