Rubber for ships

a technology for ships and rubbers, applied in the direction of hulls, steering components, floating buildings, etc., can solve the problems of rudder blade damage, before the actual rudder blade would be jeopardised, and without costa bulbs,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

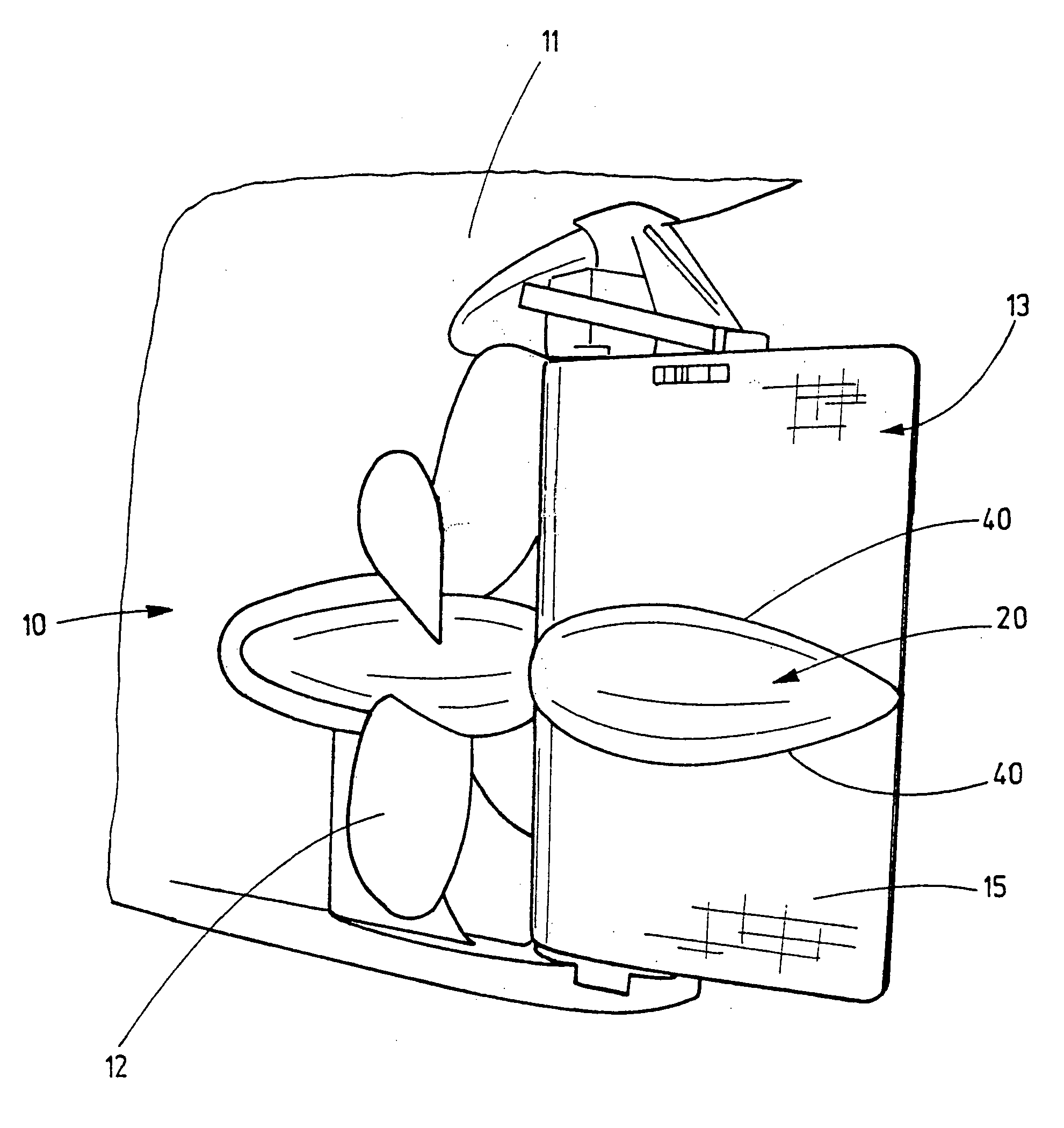

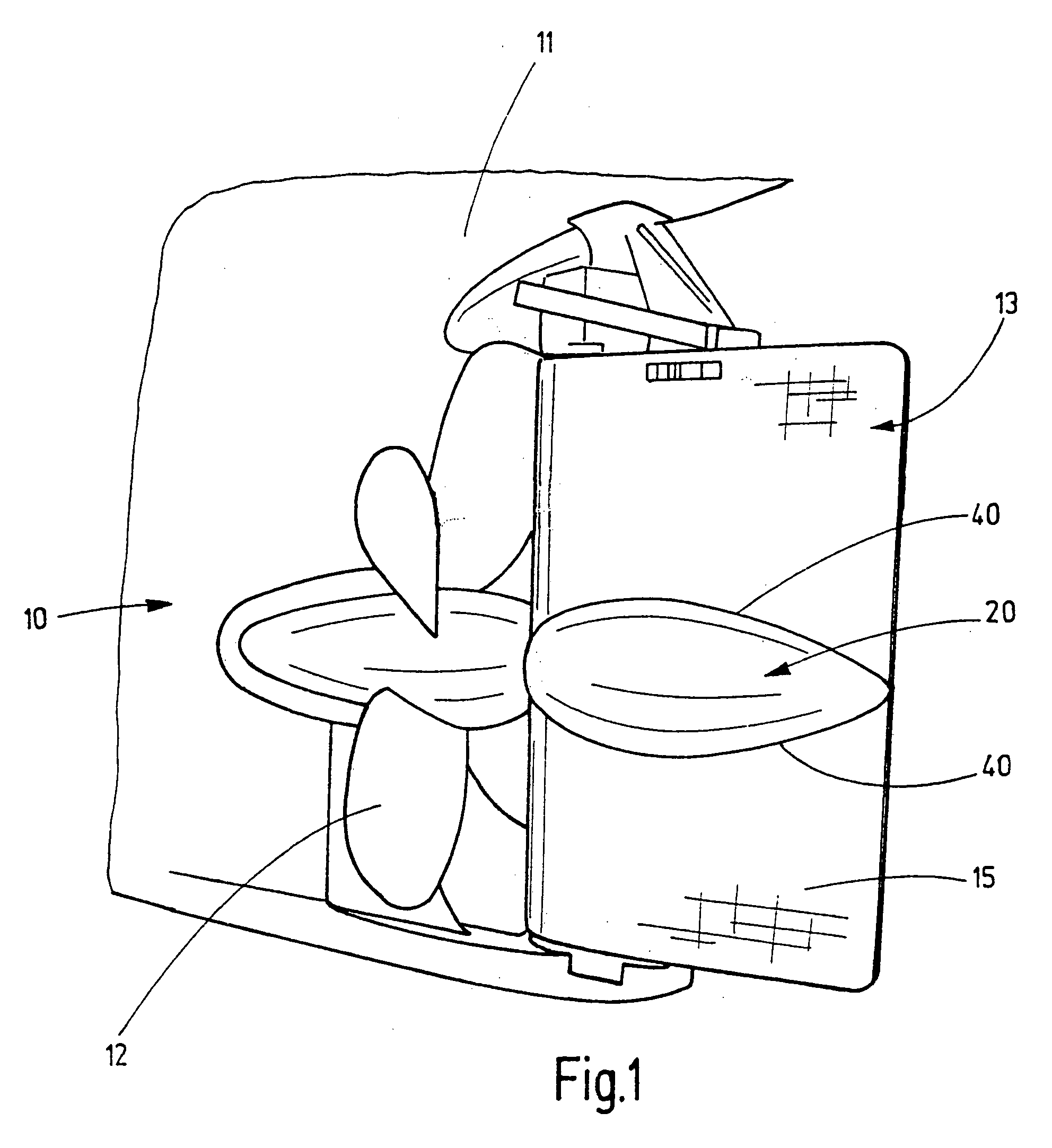

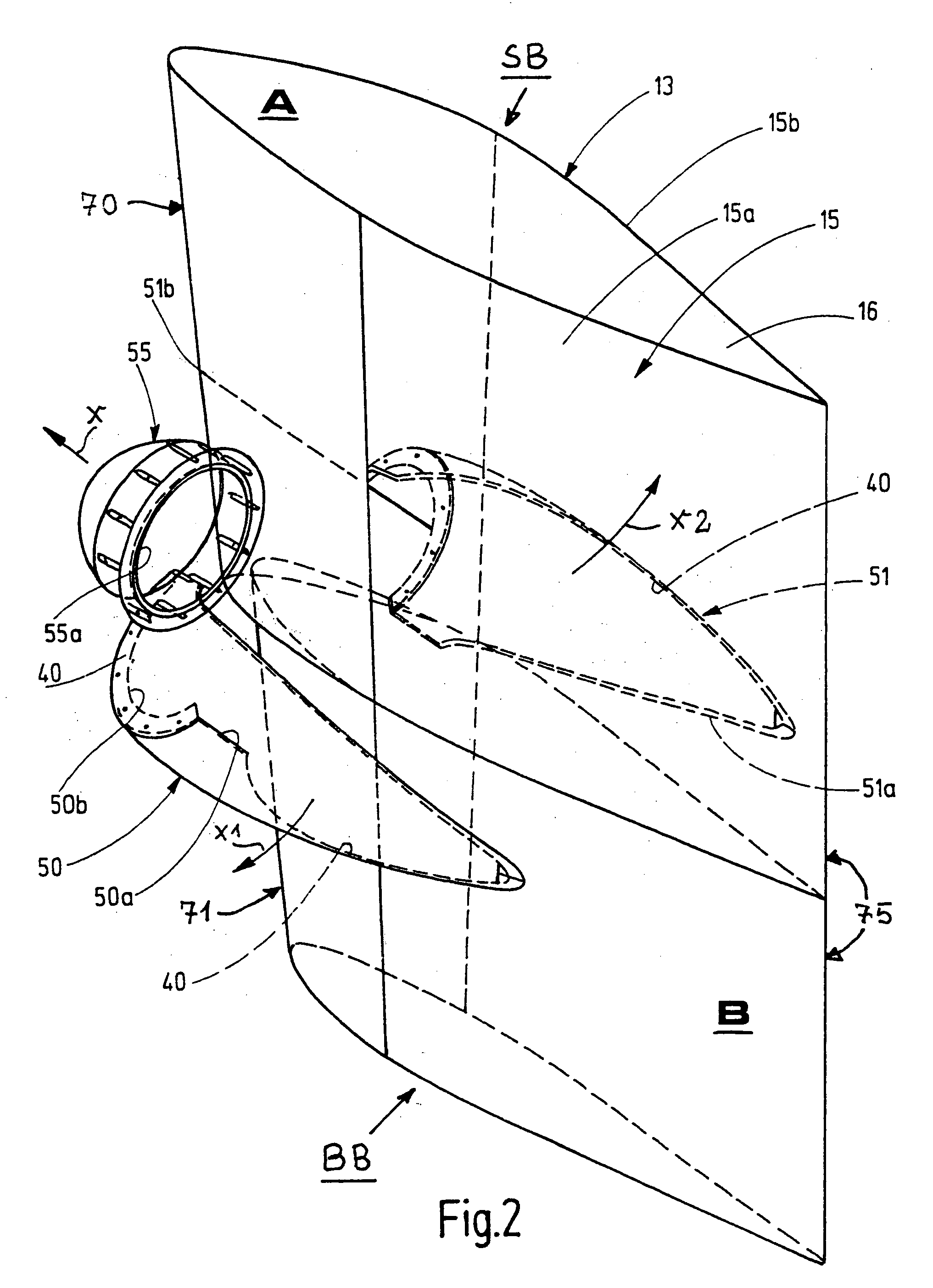

[0030]FIG. 1 shows the stem 11 of a ship 10 with a drive propeller 12 and a rudder 13, whereof the rudder blade 15 is fitted with a bulb-shaped or zeppelin-shaped flow body 20, preferably designed as a hollow body and which can be integrated into the rudder blade 15 and can comprise two or more components 21, 22, attached to the outer wall faces 15a, 15b of the rudder blade 15. The flow body 20 can also be designed as a full body. In extension of the propulsion axis a bulge, which forms the flow body 20, also known as propulsion bulb or Costa bulb, is designed in the region of the rudder blade 1.

[0031]The flow body 20 is designed such that in the event of pressure, blow or impact effect it is self-destroying.

[0032]To achieve the possibility of self-destruction, the wall 25 of the flow body 20 comprises individual wall sections 30, interconnected via predetermined break-off lines 40 in the form of material weaknesses or shear lines (FIG. 6). The predetermined break-off lines are conf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com