PTC airflow heater

a technology of airflow heater and airflow outlet, which is applied in the field of heaters, can solve the problems of not having a heat controller function, easy to malfunction, and relatively short life of the warmer, and achieve the effect of minimizing the space of wiring connection, reducing the overall size of the housing, and minimizing the length of the electric wire usag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

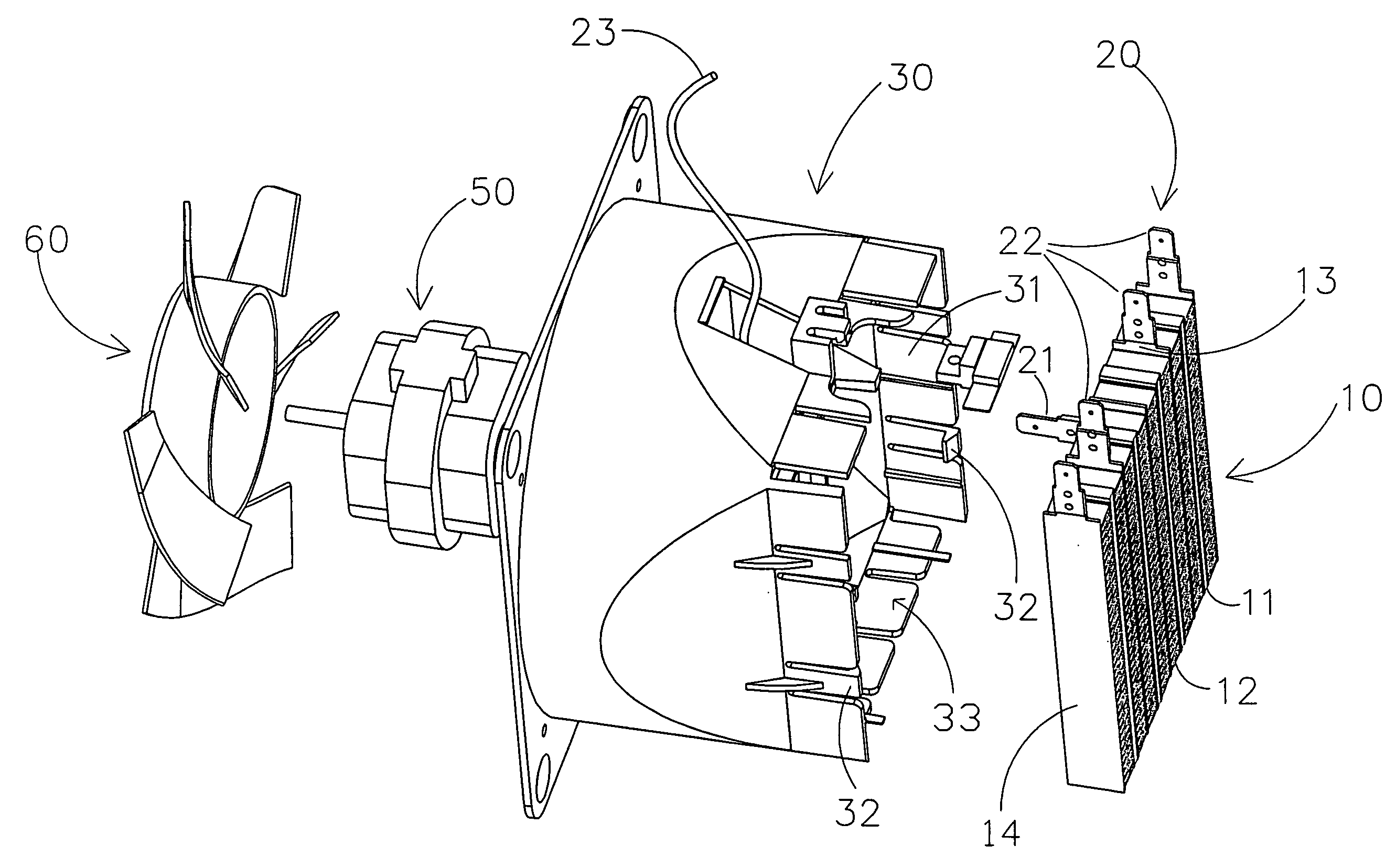

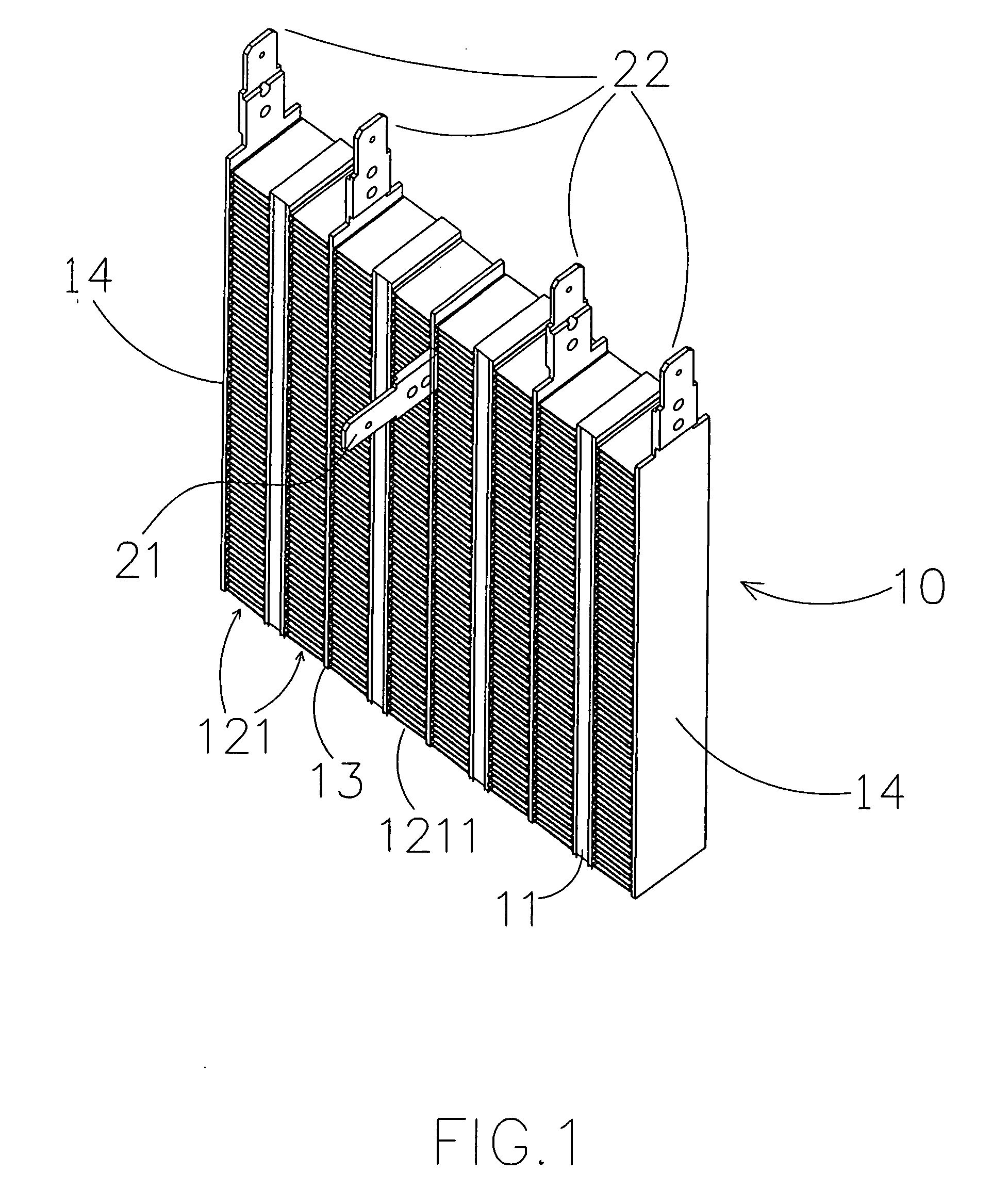

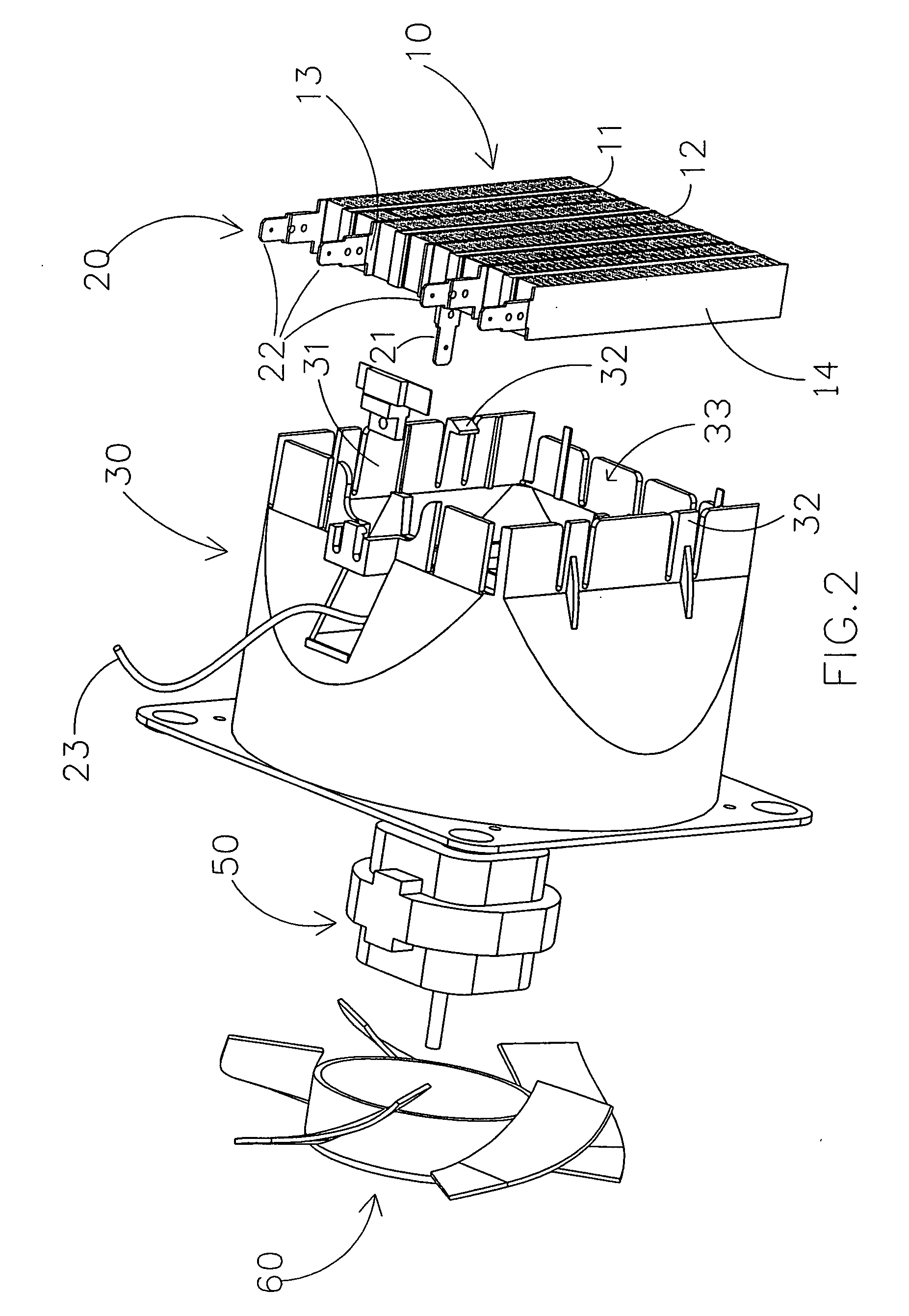

[0024]Referring to FIGS. 1 to 7 of the drawings, a PTC airflow heater according to a preferred embodiment of the present invention is illustrated, wherein the PTC airflow heater comprises a housing 70, a PTC heat generator 10 received in the housing 70, a n air source supported in the housing 70 at a position behind the PTC heat generator 10 for generating a flow of air towards the PTC heat generator. The PTC airflow heater further comprises a control arrangement supported at an upper portion of the housing 70 to control the PTC heat generator 10.

[0025]As shown in FIG. 7, the housing 70 comprises a front casing 71 and a rear casing 72 mounted thereto to define a receiving cavity between the front and rear casings 71, 72.

[0026]The air source comprises a fan blade 60 and a motor 50 driving the fan blade 60 via an output shaft to rotate so as to generate a flow of air towards the PTC heat generator 10. The control arrangement comprises a control unit 80 electrically connected between a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com