Form and method and apparatus for making a form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

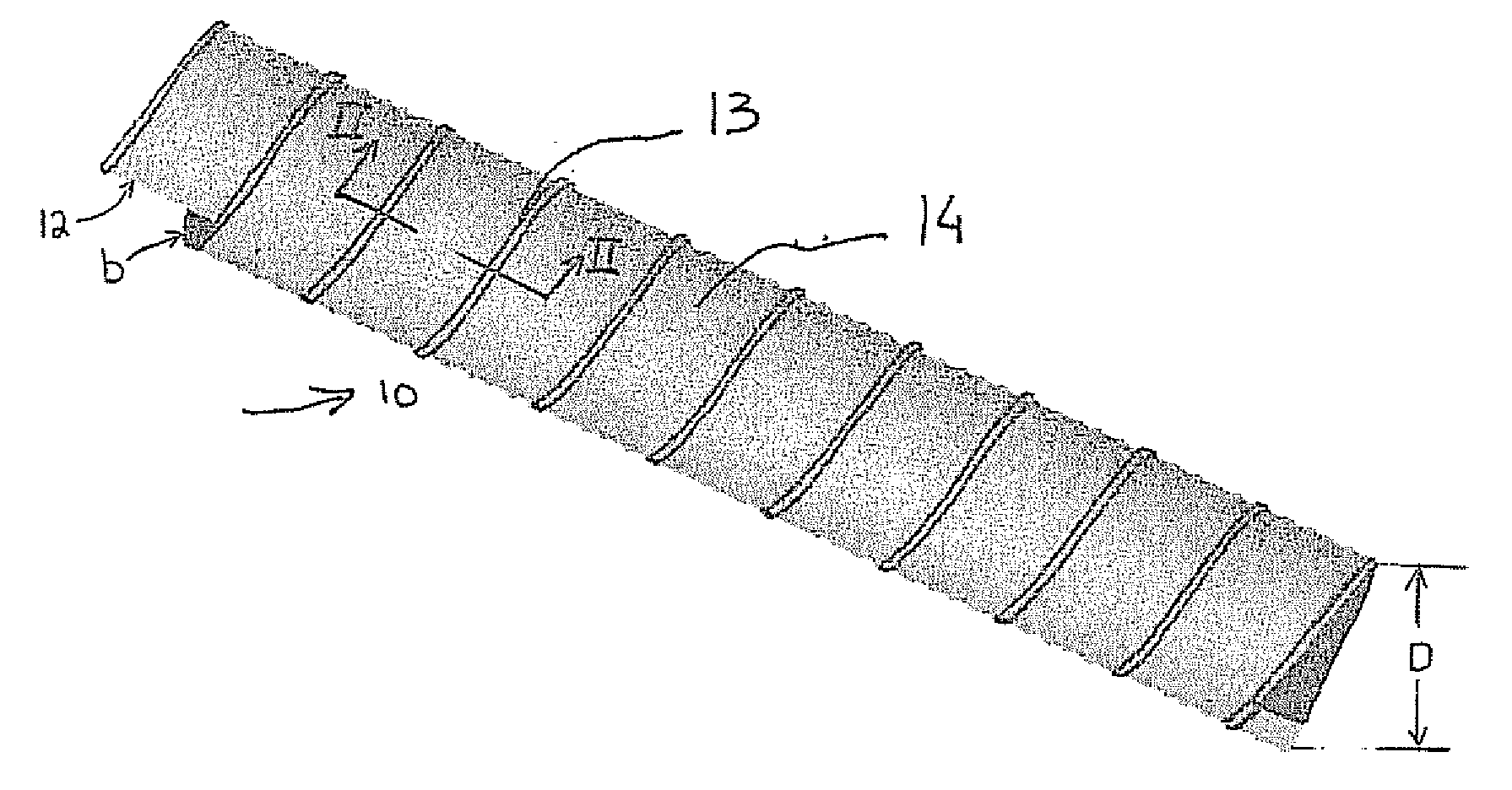

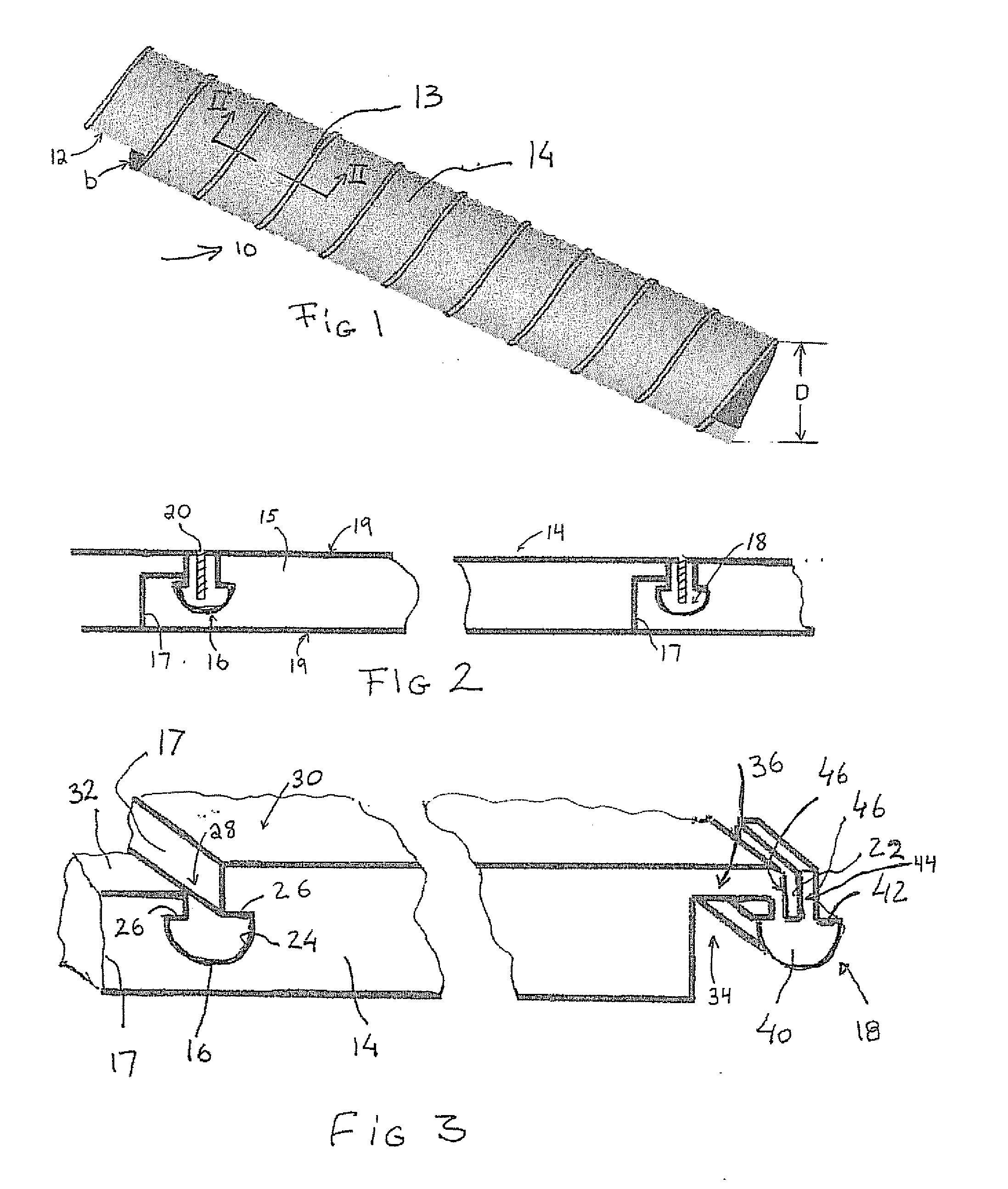

[0017]Referring therefore to FIG. 1, a form indicated by reference numeral 10 has a cylindrical wall 12 formed from a helically wound strip 14. Abutting edges of the strip 14 are interconnected by a tongue and groove joint generally indicated at 13 and seen in greater detail in FIGS. 2 and 3. The tube 10 is formed to a nominal diameter D which typically will range between 6 and 12 inches. The wall 14 has a nominal thickness indicated at b that is chosen so as to be sufficiently flexible to accommodate the radius of curvature required whilst withstanding the pressure that may be exerted when used as a form. A nominal thickness of ⅛″ is believed to be appropriate.

[0018]Referring therefore to FIG. 2, the strip 14 has a body 15 with lateral edges 17 and oppositely directed faces 19. Complementary formations in the form of a groove 16 and a tongue 18 are formed on opposite lateral edges 17. The strip 14 is preferably made from a plastics material which is flexible so as to be able to be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

| Separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com