Cleaning Body And Squeeze Mop Comprising Said Cleaning Body

a technology of cleaning body and butterfly mop, which is applied in the direction of carpet cleaners, cleaning machines, cleaning equipment, etc., can solve the problems of only comparably low cleaning performance of sponges of polyurethane, difficult to bend cleaning bodies of cellulose in dry state, and inability to absorb dirt particularly well, etc., to achieve good cleaning performance, reduce cleaning performance, and good flexibility of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

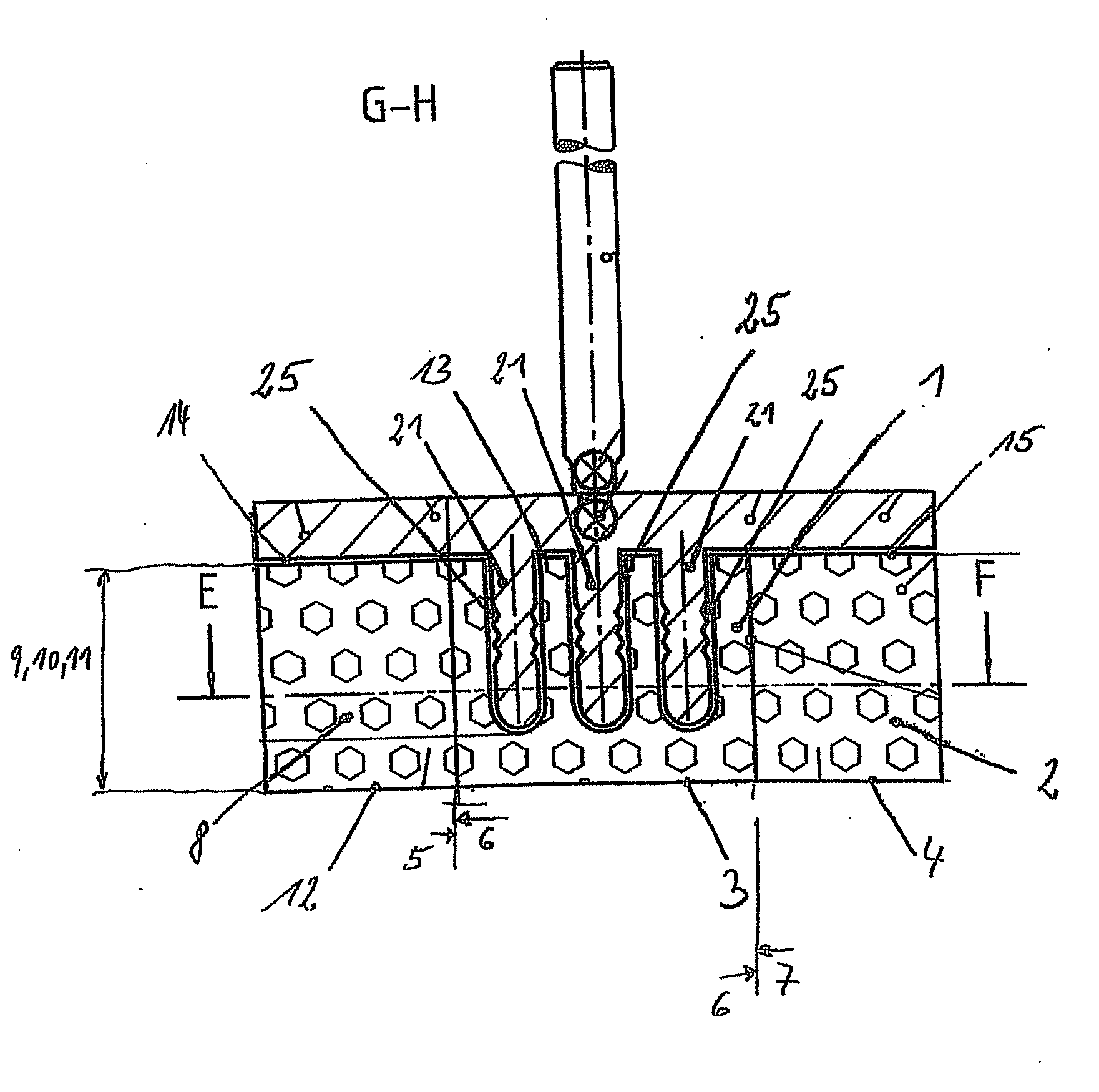

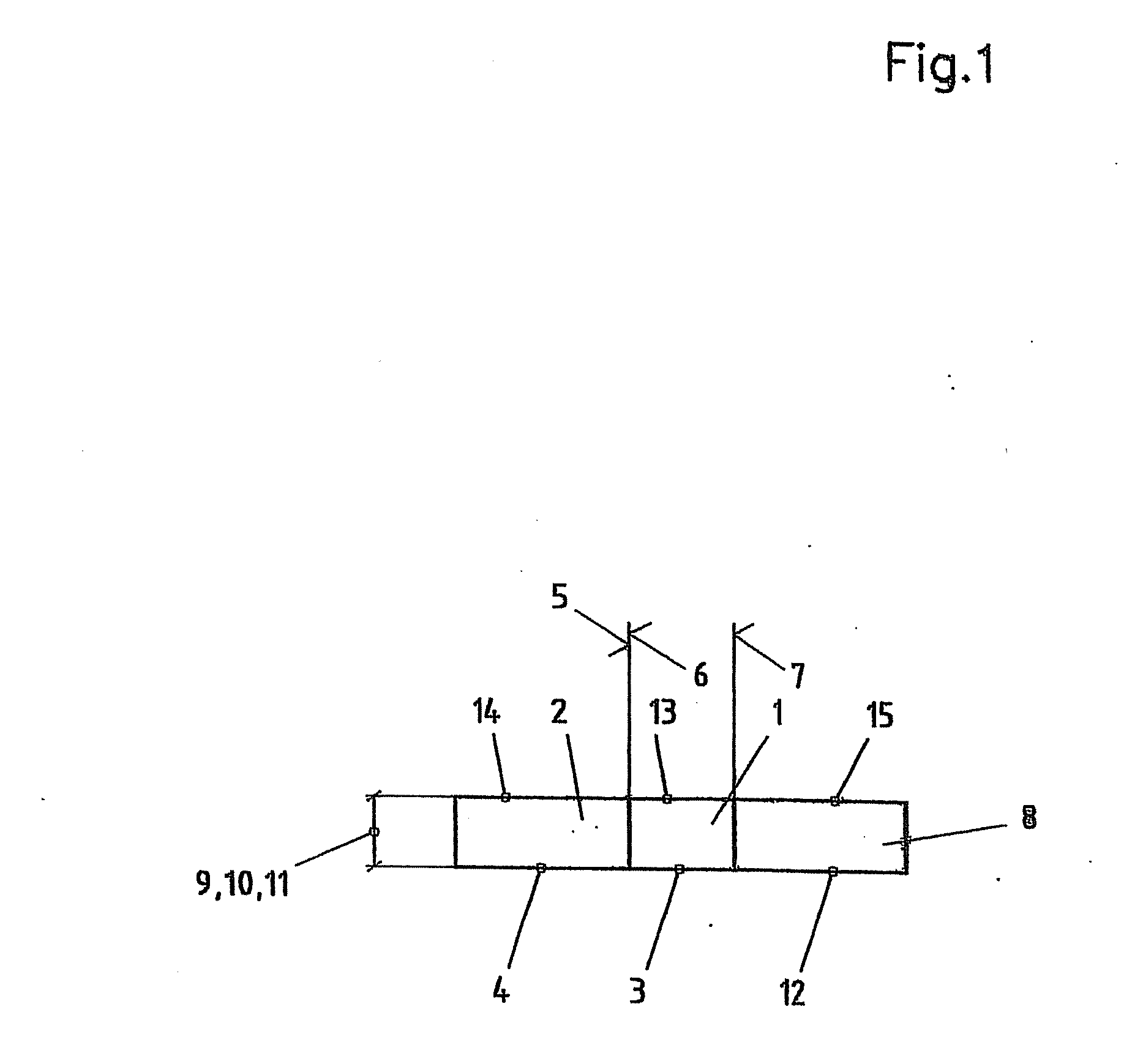

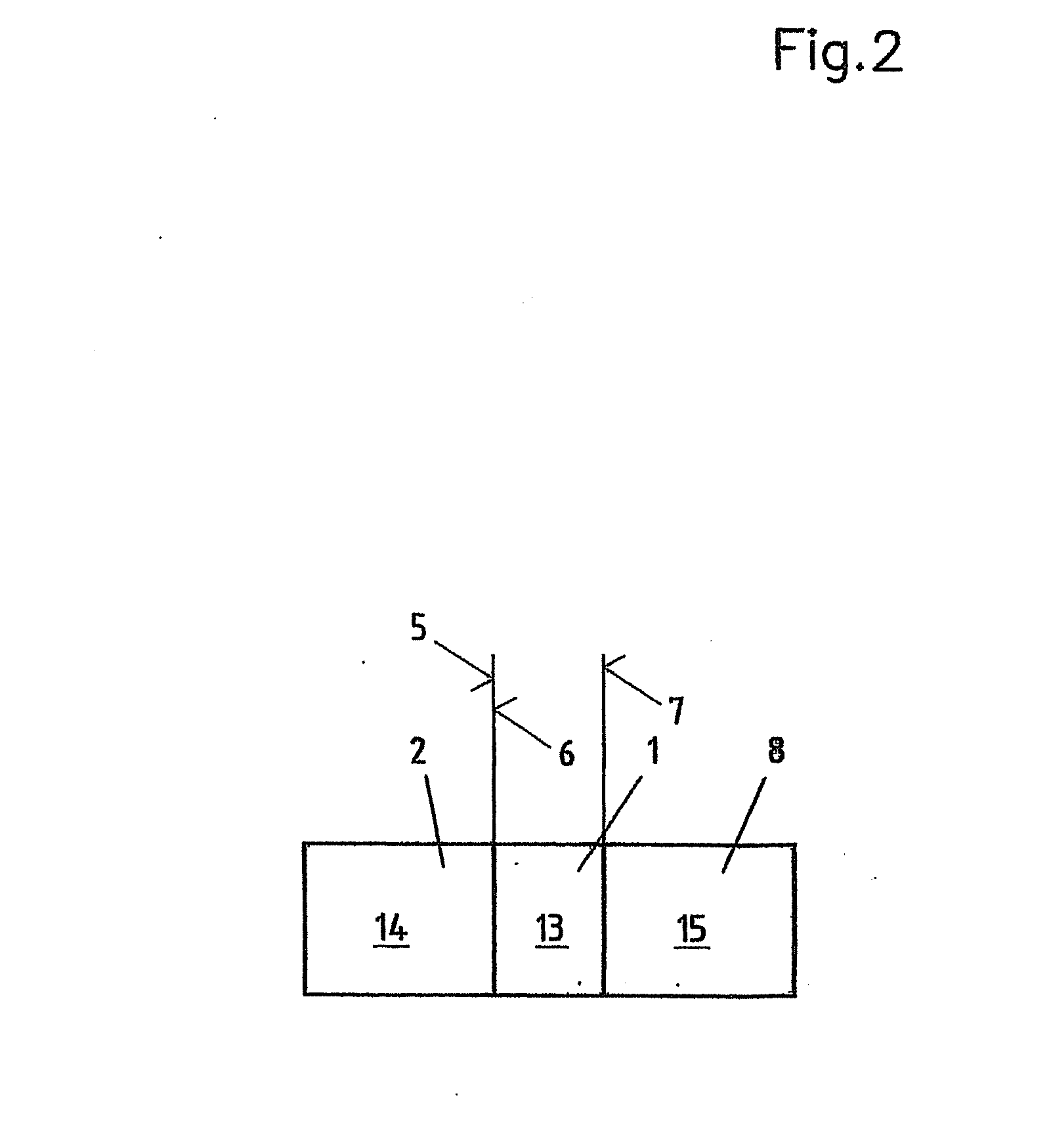

[0037]FIGS. 1-5 and 9 and 10 show five embodiment examples of a cleaning body in accordance with the invention, where the cleaning bodies shown in FIGS. 1-5 and 9 and 10 form a component of a butterfly mop in accordance with the invention in FIGS. 6-8.

[0038]The cleaning bodies in each case consist of three partial cleaning bodies 1, 2 and 8, where the first partial cleaning body in the embodiment examples shown here consists of PU, while the second and third partial cleaning body each consist of cellulose. Other materials for a wet cleaning of surfaces, for example, floors, are likewise possible, where the first partial cleaning body always has the greatest flexibility of all of the partial cleaning bodies that are used and is also readily flexible when the cleaning body is in dry state.

[0039]The three partial cleaning bodies 1, 2 and 8 each has a cleaning surface 3, 4 and 12, and are arranged next to each other and bonded together. Each partial cleaning body 1, 2 and 8, in and of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com