Tufted mop

a mop and tufted technology, applied in the field of cleaning tools, can solve the problems of troublesome cleaning of the mop mat and the mop head after use, easy rust and oxidation of the fasteners used to fix the mop head, and easy damage of the mop strip, etc., to achieve easy cleaning, easy replacement and removal, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

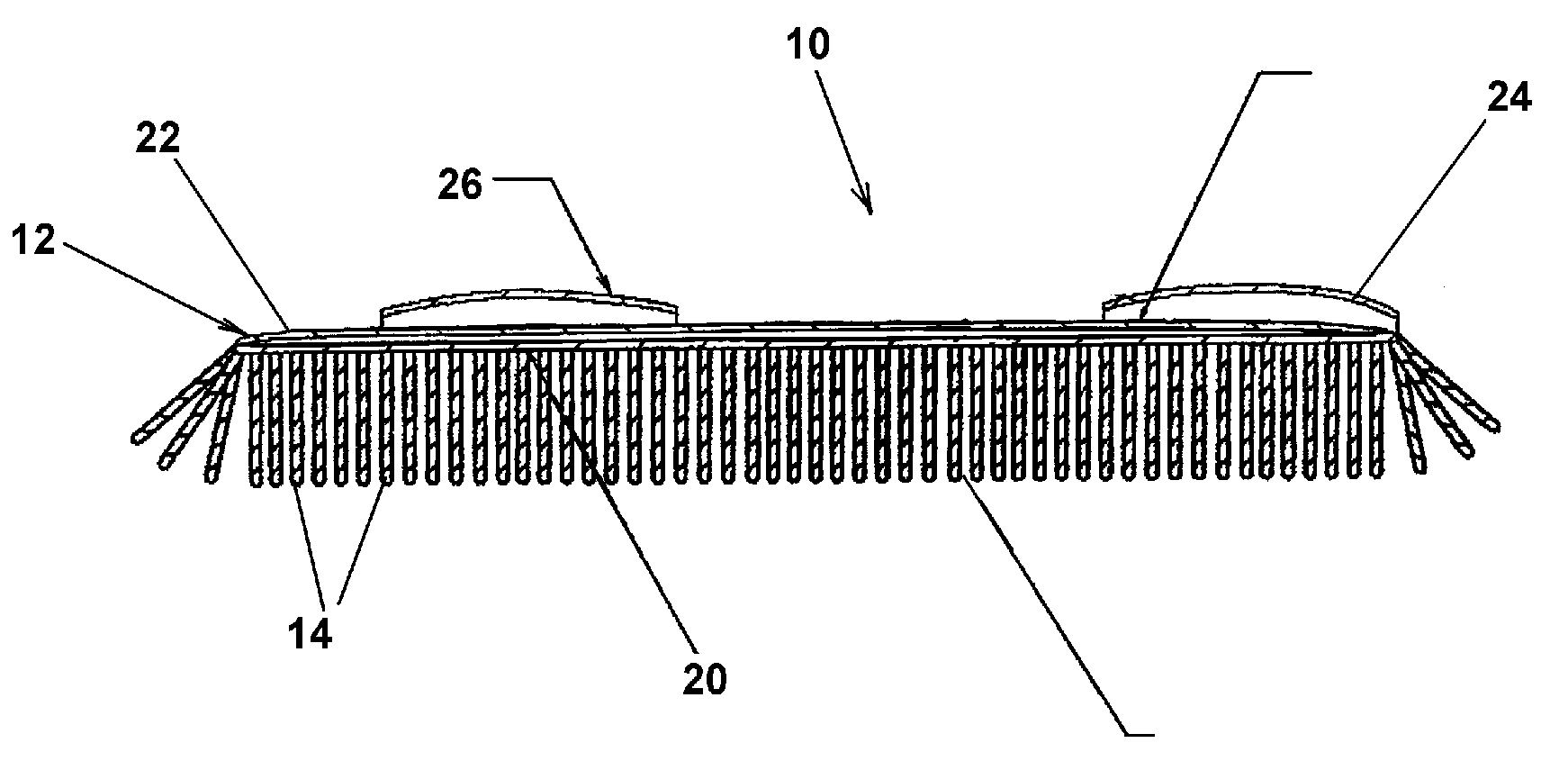

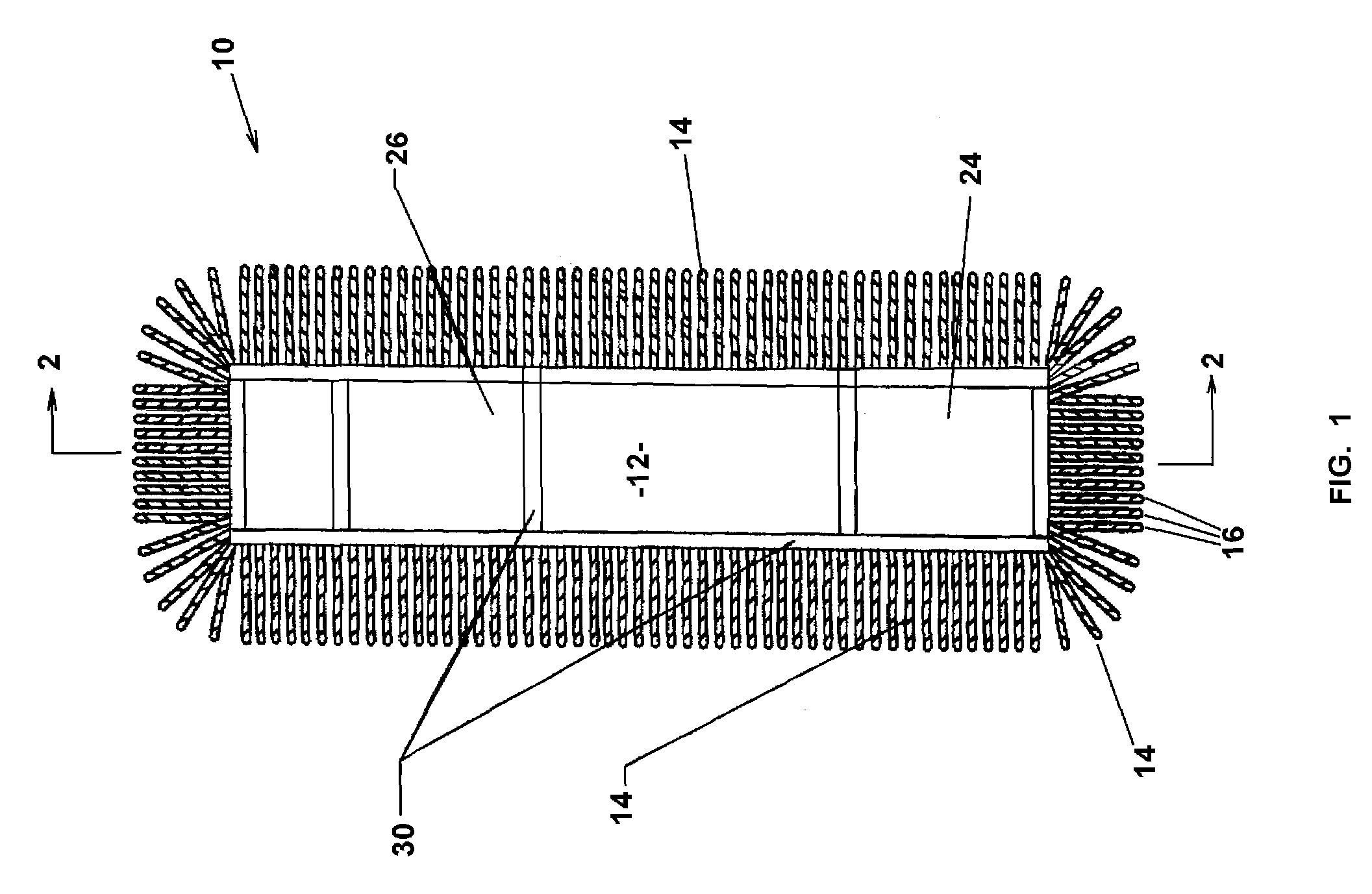

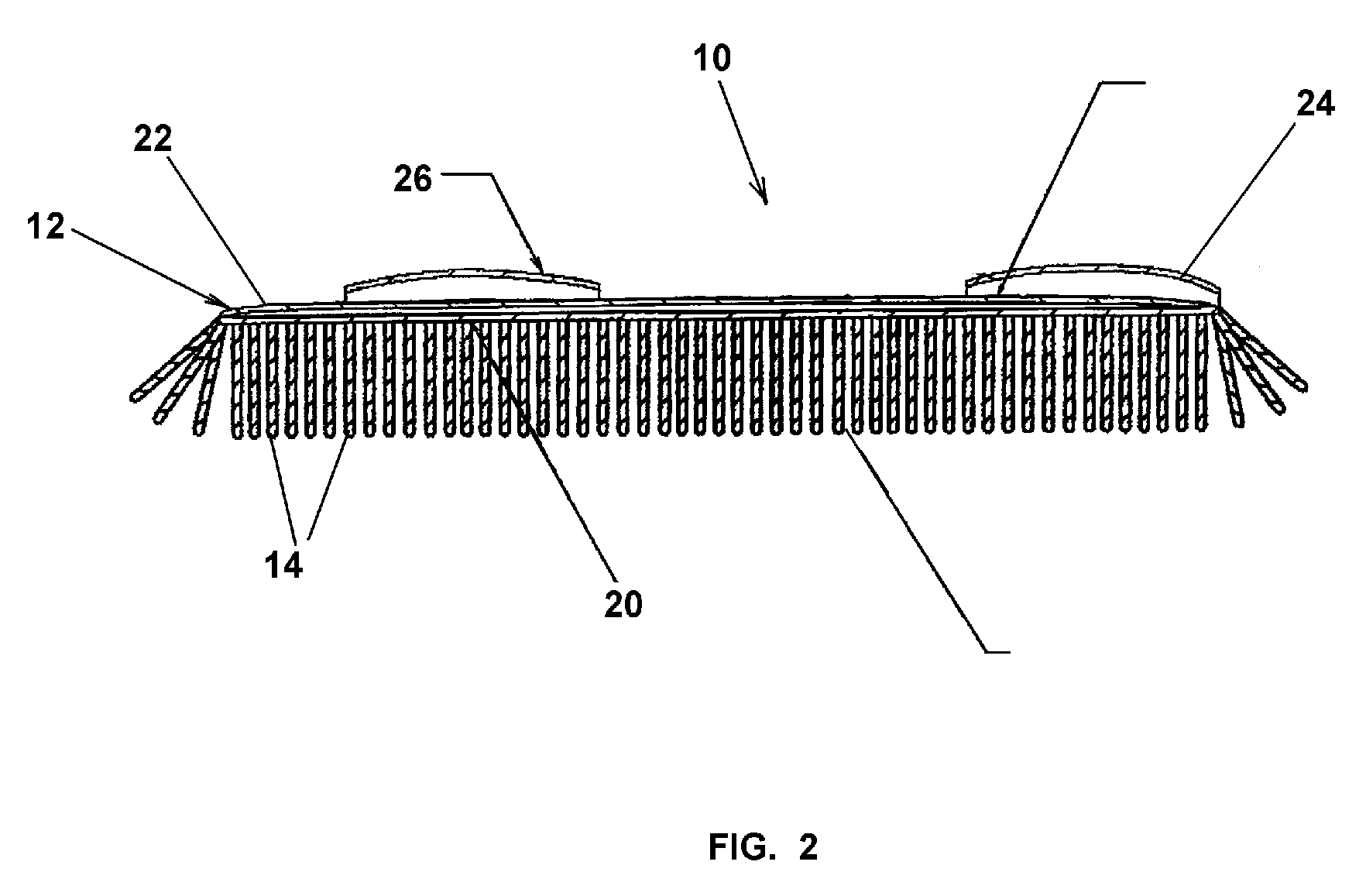

[0009]Referring to FIGS. 1 and 2, there is shown a tufted mop 10 in accordance with an embodiment of the invention is a flat format for the wet or dry mopping of a surface. The mop 10 configured for non-fastener assembly with a frame-type mop head as described below. On the surface, the mop elements or tufts are arrayed in longitudinal row beneath the mop and orient outwardly about the perimeter as shown.

[0010]The mop 10 comprises a backing assembly 12 carrying a plurality of tufted mop elements 14 in longitudinal rows 16. The backing assembly 12 includes a rectangular backing panel 20 on which the mop elements 14 are tufted. The backing assembly 12 includes a lining panel 22 that overlies the backing panel 20. The mop frame is retained on the mop at by a first fastener block 24 in the form of a pocket at one end of the lining panel 22 and by a second retain block in the form of an open ended sleeve 26 spaced inwardly of the other end. The block 24 is stitched to the lining panel 22...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com