Ductless dryer

a dryer and ductless technology, applied in the direction of drying machines, drying machines, light and heating equipment, etc., can solve the problems of inability to use gas as heating source in the room in which the dryer is situated, and the noise in the room may not be quiet, so as to achieve the effect of attenuating the nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

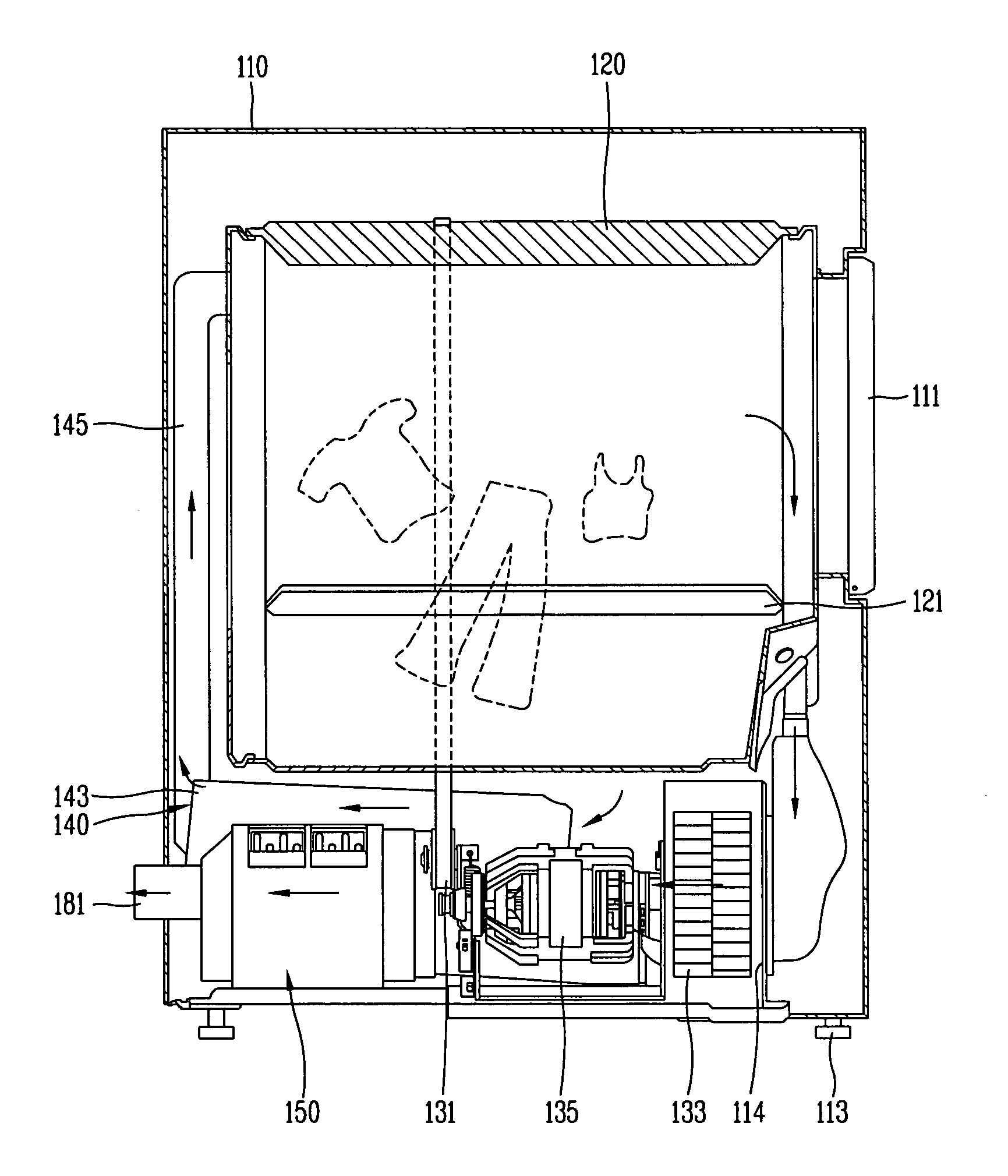

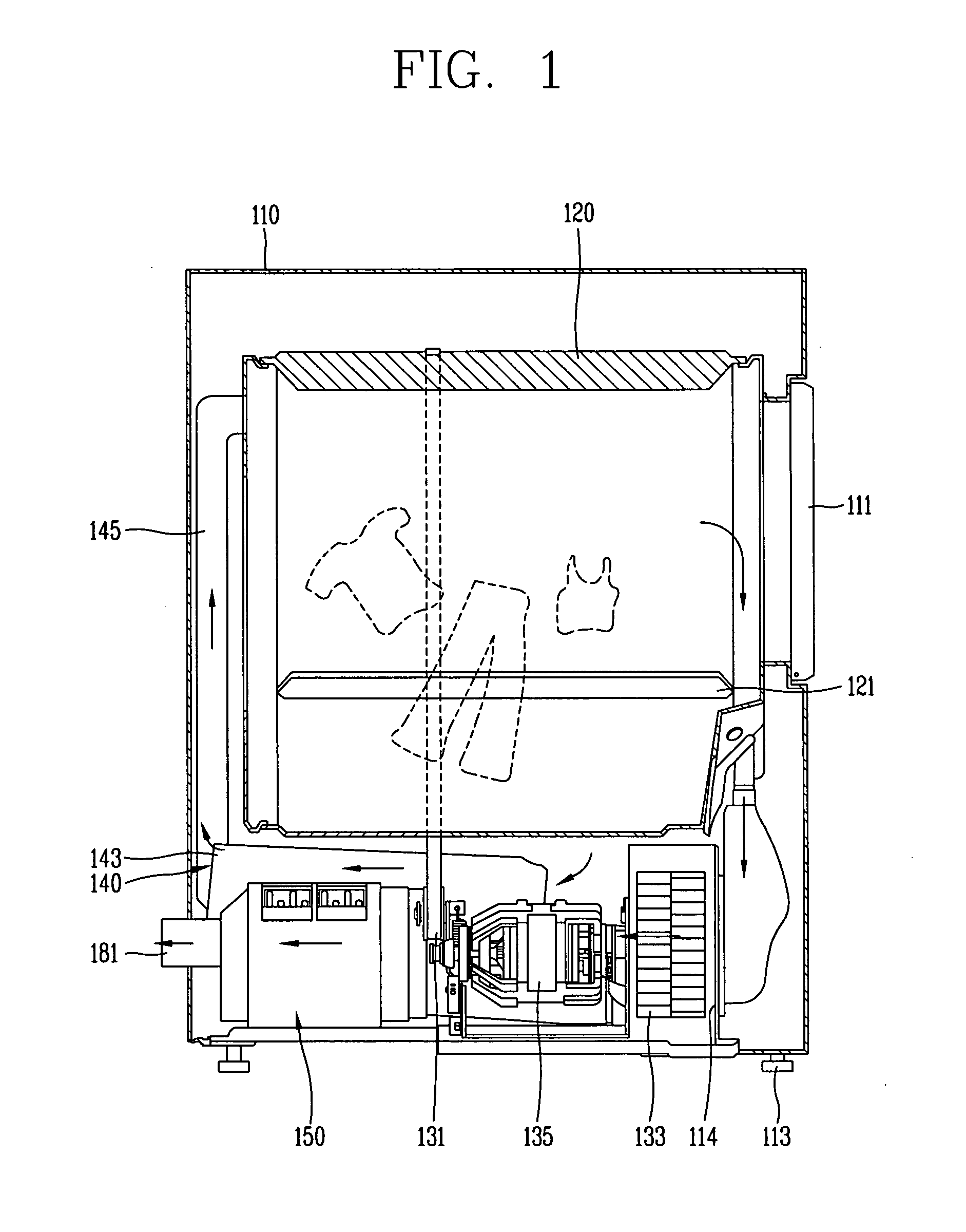

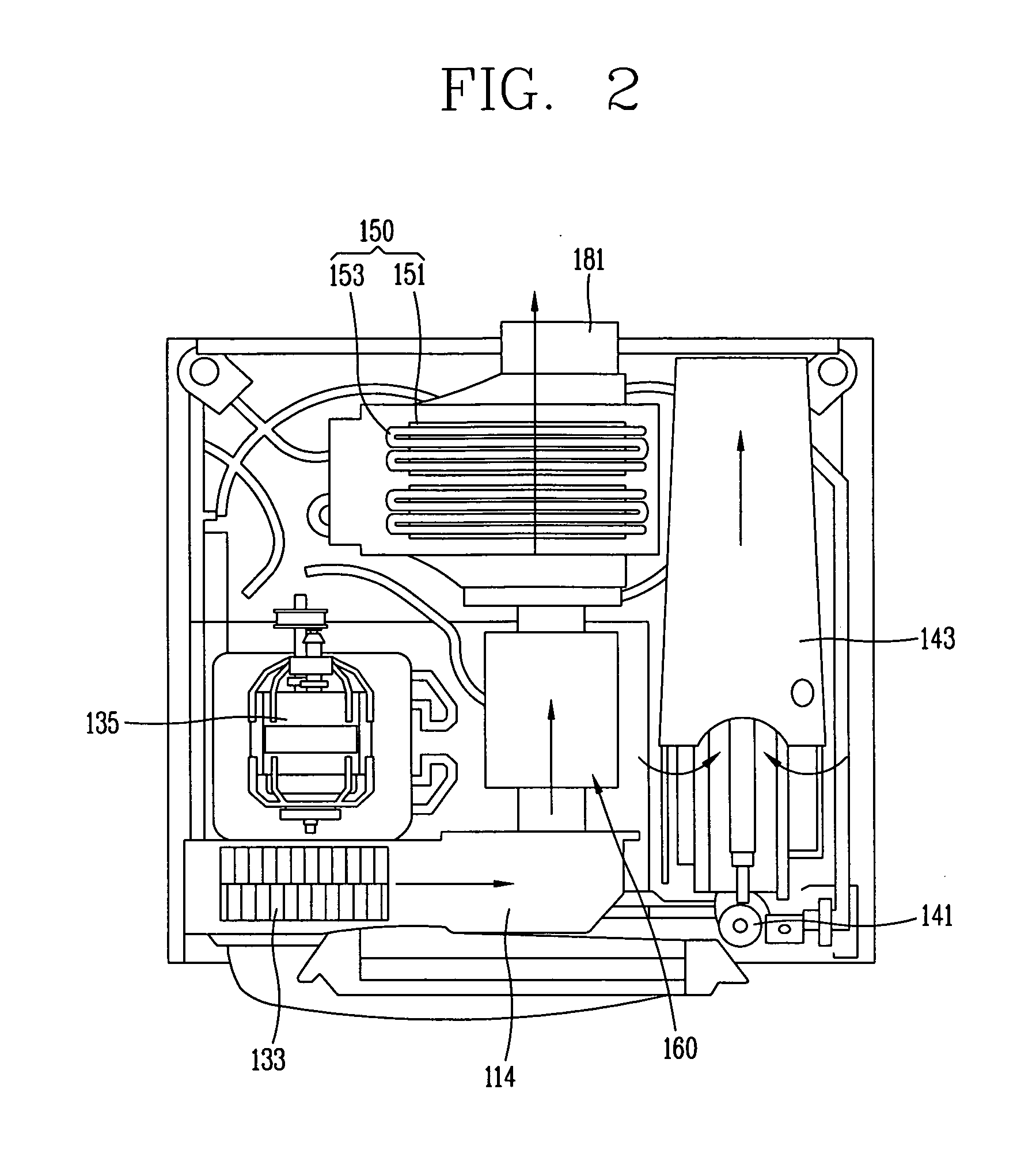

[0030]Referring to FIGS. 1 and 2, the ductless dryer having the noise reduction portion in accordance with the present invention includes a main body 110, a drum 120 rotatably installed at the main body 110, a hot air supplying unit 140 providing hot air into the drum 120, a heat exchange unit 150 condensing moisture included in the air exhausted from the drum 120 through heat exchange with cooler exterior air, a circulation duct 114 conducting the air exhausted from the drum 120 to the heat exchange unit 150, an exhaust duct 181 conducting the air exhausted from the heat exchange unit 150 outside the dryer, and a noise reduction portion 160 for attenuating noise so as to prevent the noise from being transferred through the exhaust duct 181. Herein, the noise reduction portion 160 may be installed between the circulation duct 114 and the heat exchange unit 150 in consideration of a limitation of space inside the dryer. Further, the noise reduction portion 160 may be connected inline...

second embodiment

[0049]FIG. 9 is a perspective schematic diagram showing a noise reduction portion in accordance with the present invention and a noise level test setup therefor, FIG. 10 is a diagram showing a cross-section X-X of the noise reduction portion in FIG. 9, FIG. 11 is a diagram showing a cross-section XI-XI of the noise reduction portion in FIG. 9, and FIG. 12 is a graph comparing results of noise level measurements according to varying the number of noise reduction portion exhaust openings in the noise reduction portion in FIG. 9.

[0050]Referring to FIGS. 9 and 10, the noise reduction portion 170 in accordance with the second embodiment of the present invention includes an inner pipe 171 and an outer pipe 173 forming a space S by enclosing a part of or the entire inner pipe 171. A plurality of openings 171a in communication with the space S are formed in the surface of the inner pipe 171.

[0051]Preferably, the outer pipe 173 encloses the entirety or a part of the inner pipe 171 so as to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com