System Reheat Control by Pulse Width Modulation

a technology of pulse width and reheat capacity, applied in the direction of lighting and heating apparatus, machine operation mode, heating type, etc., can solve the problems of not being utilized to provide varying steps in reheat capacity, and the refrigerant system designer is faced with challenges, and achieve the effect of overall system performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

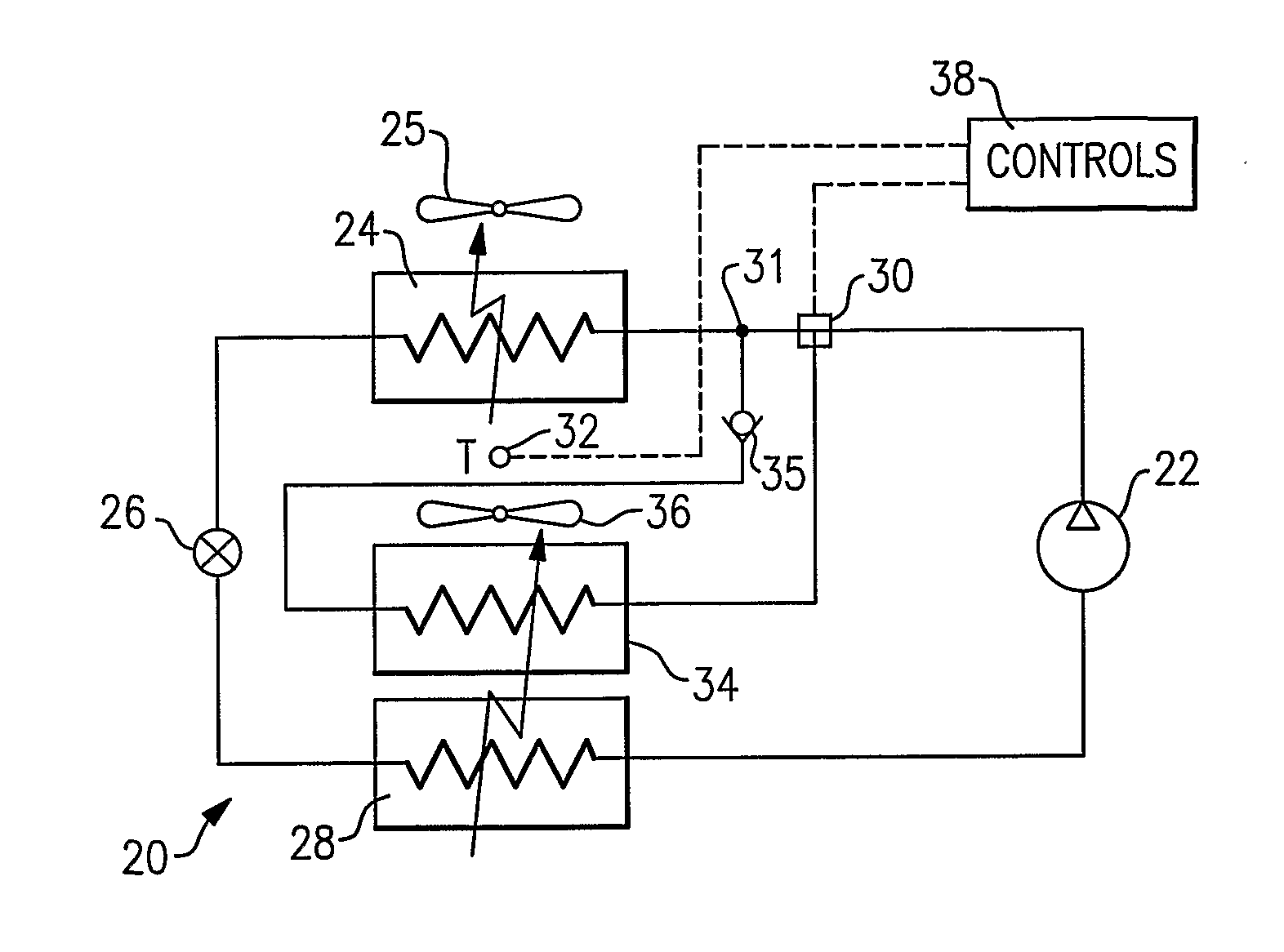

[0012]A refrigerant system 20 is illustrated in FIG. 1 including a compressor 22 compressing refrigerant and delivering it to a downstream condenser 24. A fan 25 blows air over the condenser 24. Refrigerant passes from the condenser 24 to a downstream expansion device 26, then to an evaporator 28, and finally returns to compressor 22. A three-way valve 30 is placed on a discharge refrigerant line, and as illustrated, between the compressor 22 and the condenser 24. The three-way valve 30 is controlled by a control 38 for a purpose that will be described below. When the three-way valve is in an open position, it will deliver refrigerant through a reheat heat exchanger 34 and a check valve 35, and then return the refrigerant back to a position 31 still upstream of the condenser 24. As is known, a fan 36 blows air over the evaporator 28, and the reheat heat exchanger 34 is placed such that it is in the path of that air stream behind the evaporator 28.

[0013]The purpose of the reheat heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com