Elevated toilet seat

a toilet seat and hinge technology, applied in the field of toilet seats, can solve the problems of user injury, sludge off the toilet seat, and inconvenient cleaning, and achieve the effect of convenient cleaning and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

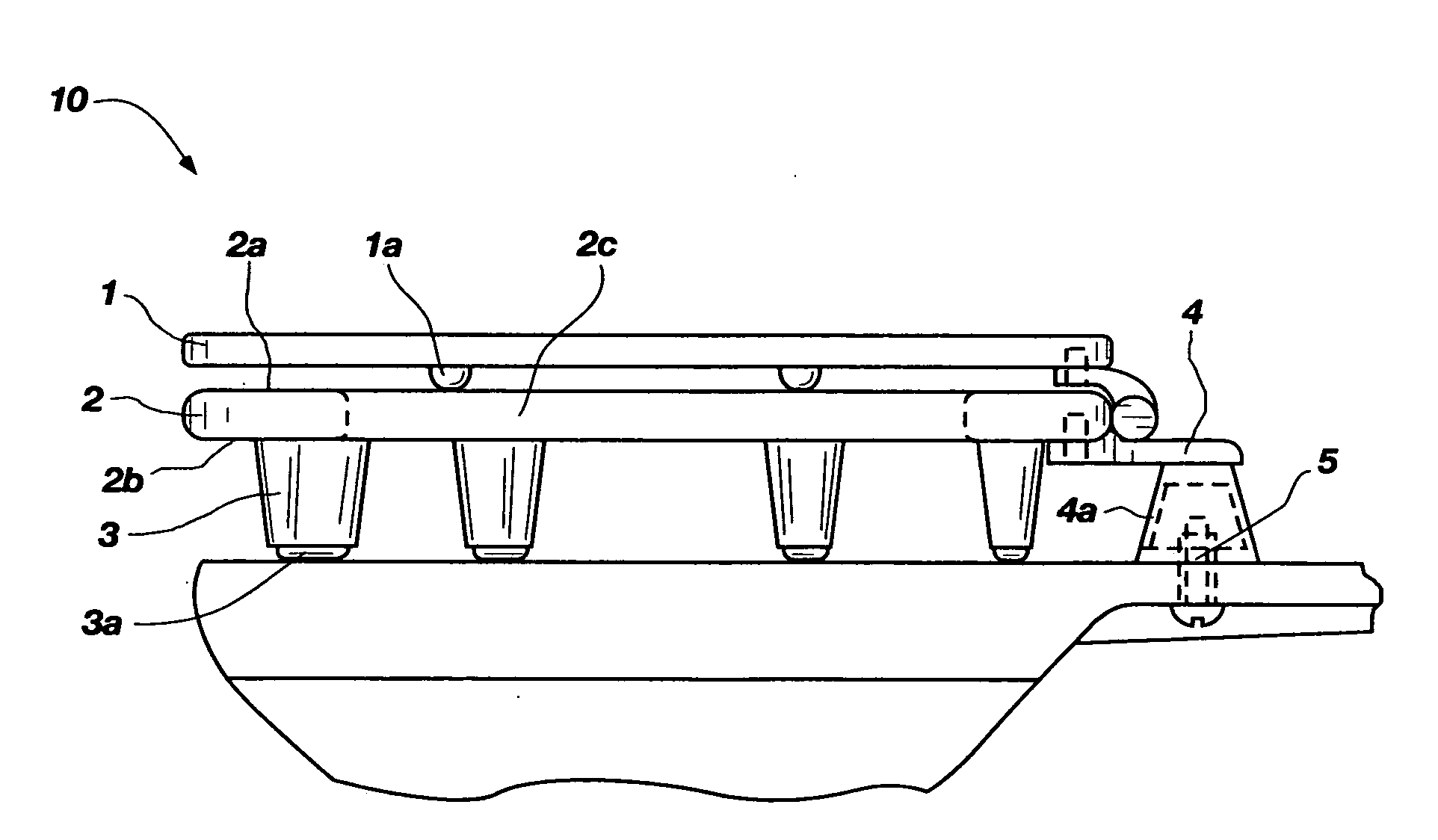

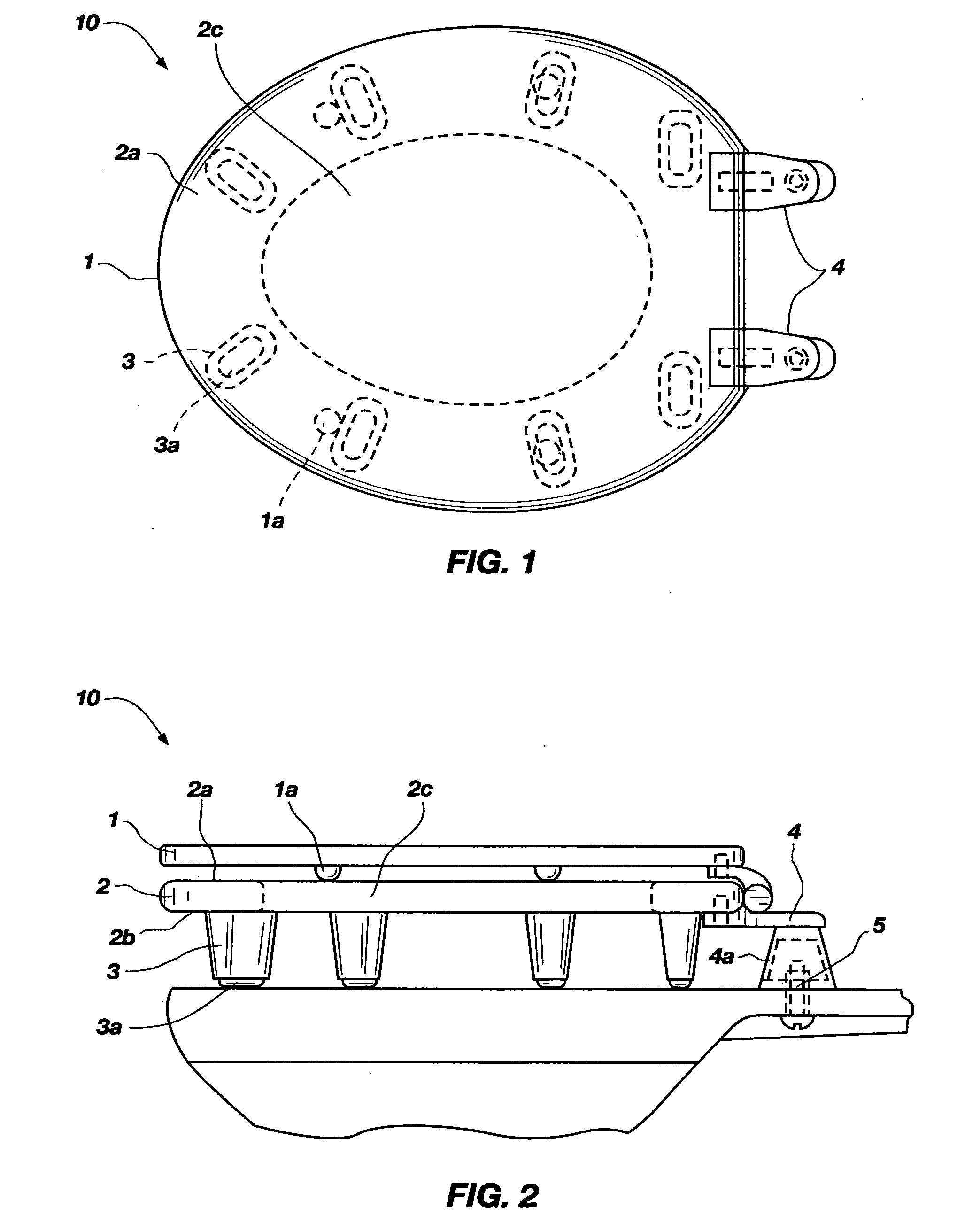

[0033]One preferred embodiment of the elevated toilet seat 10 is shown in the attached drawings FIG. 1 (top view), FIG. 2 (side view). It comprises a raised toilet seat system 10, which has the surface 2a of the toilet seat 2 raised approximately two inches to make it easier for sitting down and getting up. The toilet seat 2 is sized to fit onto the rim of a toilet bowl. It has a top surface 2a with rounded edges associated with a flat planar bottom 2b to form an elevated seat 2 of solid cross section defining a center hole 2c as shown in FIGS. 1 and 2.

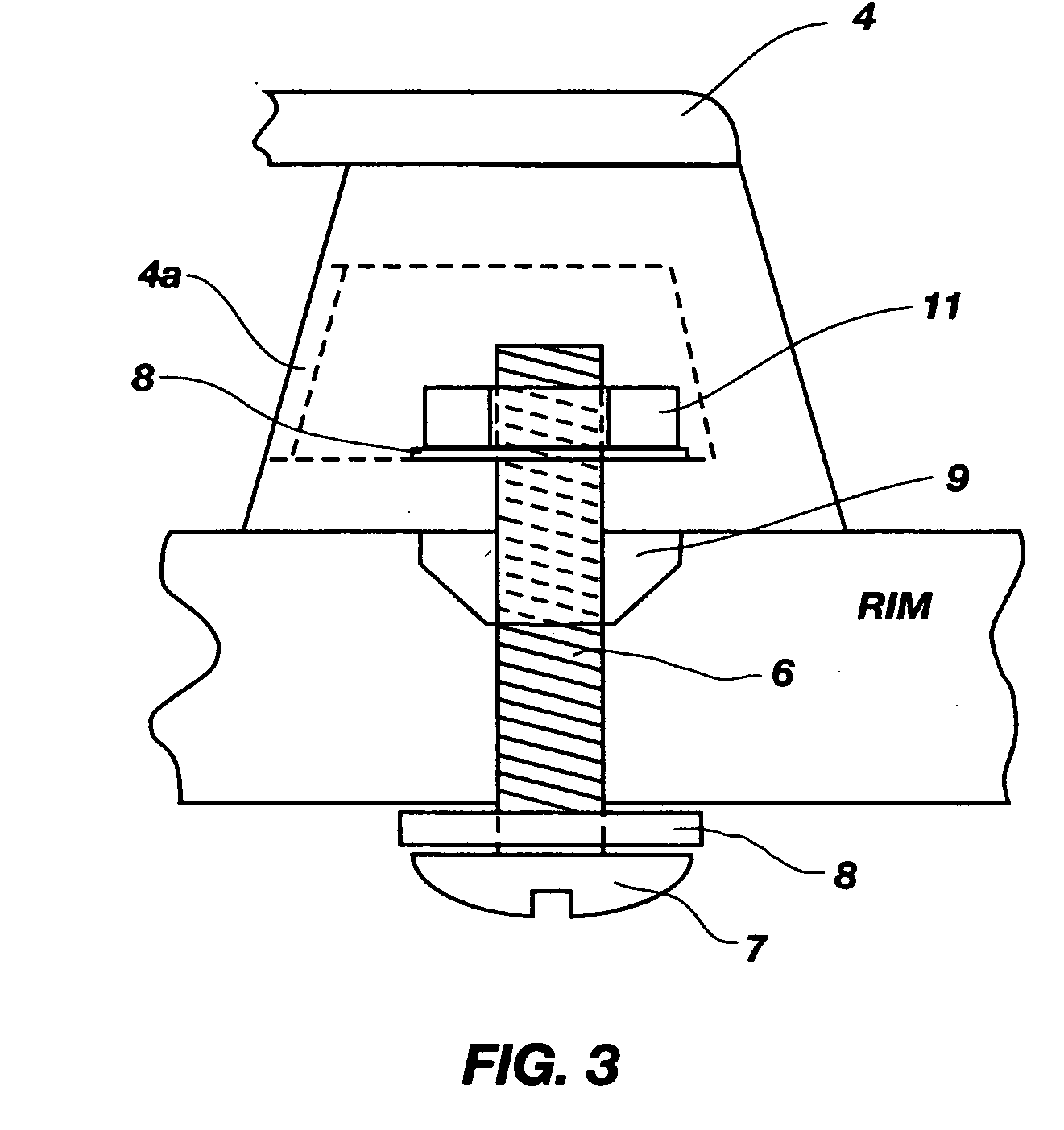

[0034]The embodiment shown in FIGS. 1 and 2 has a hinged lid 1 attached to a toilet seat 2 with eight integral two inch high pedestals 3 molded integral to its bottom 2b to contact a toilet bowl when lowered for use. This embodiment is used to support very heavy users, or where the seat 2 is constructed of a material with lower tensile strength. The lid 1 has rubber cushions 1a on the underside structured to contact the seat 2 and min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com