Solvent absorbing device and image forming apparatus

a technology of solvent absorbing device and image forming apparatus, which is applied in the direction of vacuum evaporation coating, printing, coating, etc., can solve the problems of recording medium wrinkles, wrinkling of recording medium, and liable to occur, so as to promote the collection of excess solvent, the effect of no decline in absorption properties and prescribed absorption performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

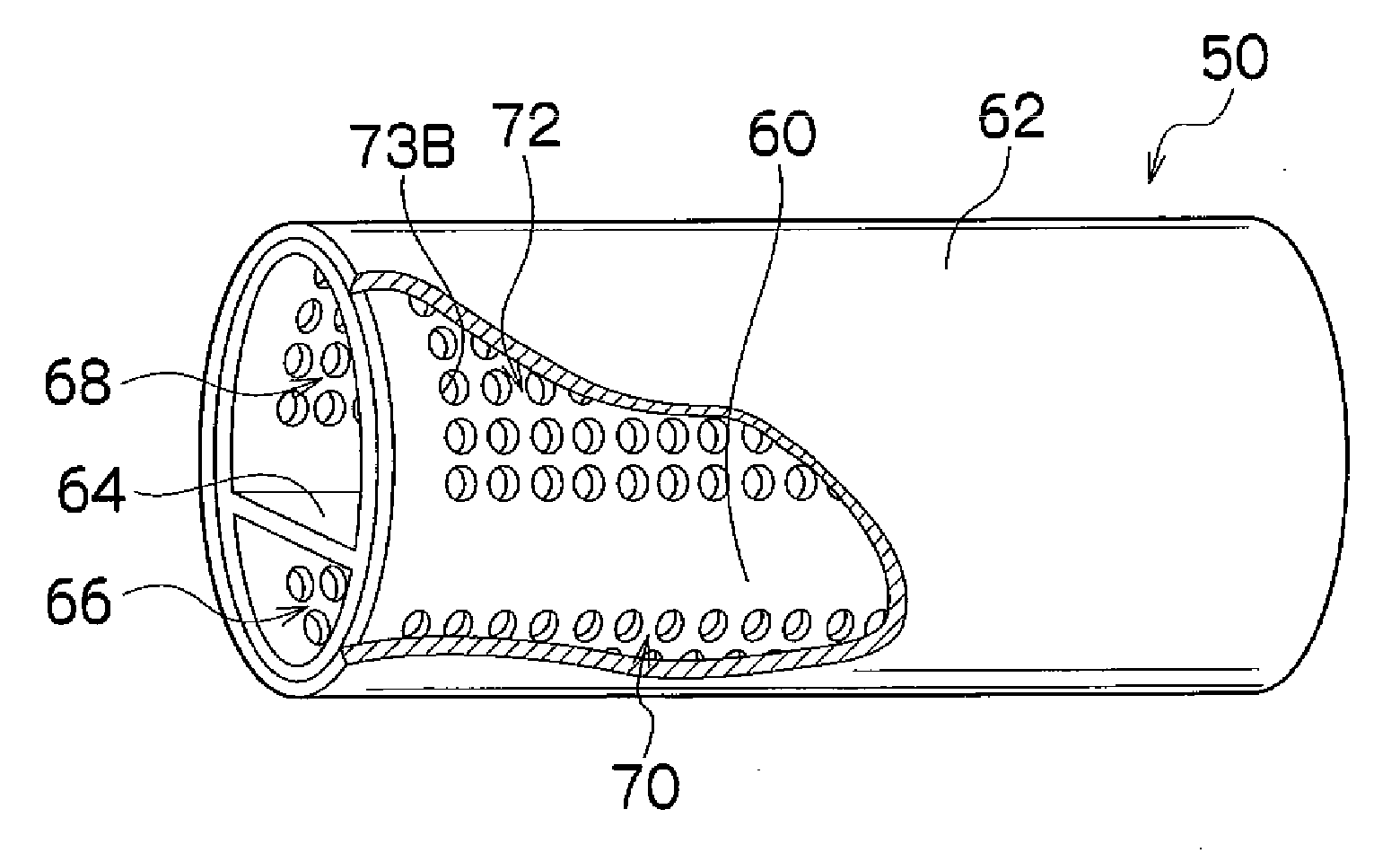

[0080]FIG. 4 is a schematic drawing showing the composition of the solvent absorbing device according to a first embodiment. In FIG. 4, numeral 50 denotes a solvent removing roller, 52 denotes a nonpermeable medium, 54 denotes ink and treatment liquid (coloring material aggregating reaction liquid), 56 denotes coloring material (colorant), and 58 denotes a solvent. The non-permeable medium 52 corresponds to the intermediate transfer body 12 (in FIG. 1) or 12A (in FIG. 3A) or the recording medium 14B (see FIG. 3B), which is used in the above-described inkjet recording apparatus. The coloring material 56 is formed by pigment particles or dye that has aggregated and formed particles. FIG. 4 shows a mode where, when the non-permeable medium 52 having the ink 54 deposited on the surface thereof is conveyed in the medium conveyance direction (the direction of an arrow A in FIG. 4), then a portion of the solvent 58 (the excess solvent) on the non-permeable medium 52 is removed by the solve...

second embodiment

[0102]Next, a solvent absorbing device according to the second embodiment of the present invention is described. Below, the parts common with the first embodiment described above are not explained further, and the following description centers on the characteristic features of the second embodiment.

[0103]FIG. 6 is a schematic drawing showing the composition of the solvent absorbing device according to the second embodiment. In FIG. 6, the parts common or similar with those in FIG. 4 are denoted with the same reference numerals.

[0104]The solvent absorbing device shown in FIG. 6 has a check valve 80 arranged in the partition 64, which divides the interior of the hollow open roller 60 into the first and second spaces 66 and 68, and the suction device 74 is connected only to the first space 66. The check valve 80 is configured to be openable and closeable in accordance with the pressure difference between the first and second spaces 66 and 68, and when the check valve 80 is in the close...

third embodiment

[0109]Next, a solvent absorbing device according to the third embodiment of the present invention is described. Below, the parts common with the above-described embodiments are not explained further, and the following description centers on the characteristic features of the third embodiment.

[0110]FIG. 7 is a schematic drawing showing the composition of the solvent absorbing device according to the third embodiment. In FIG. 7, the parts common or similar with those in FIG. 4 are denoted with the same reference numerals.

[0111]In the solvent absorbing device shown in FIG. 7, the suction device 74 is connected to the first space 66 and a pressurization device 82 is connected to the second space 68. Since the negative pressure is applied to the first space 66 by the suction device 74, then it is possible to promote the collection of the excess solvent by the absorbing body 62 through the first opening section 70. On the other hand, since a positive pressure (i.e., a pressure higher than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com