Plates and prototype workpieces produced with a device for performing a fast prototyping process

a technology for prototyping and plate production, applied in the direction of additive manufacturing process, metal rolling arrangement, additive manufacturing with liquids, etc., can solve the problems of unfavorable process economics, waste of materials, and waste of materials, so as to improve the efficiency of the overall prototyping process and facilitate material supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

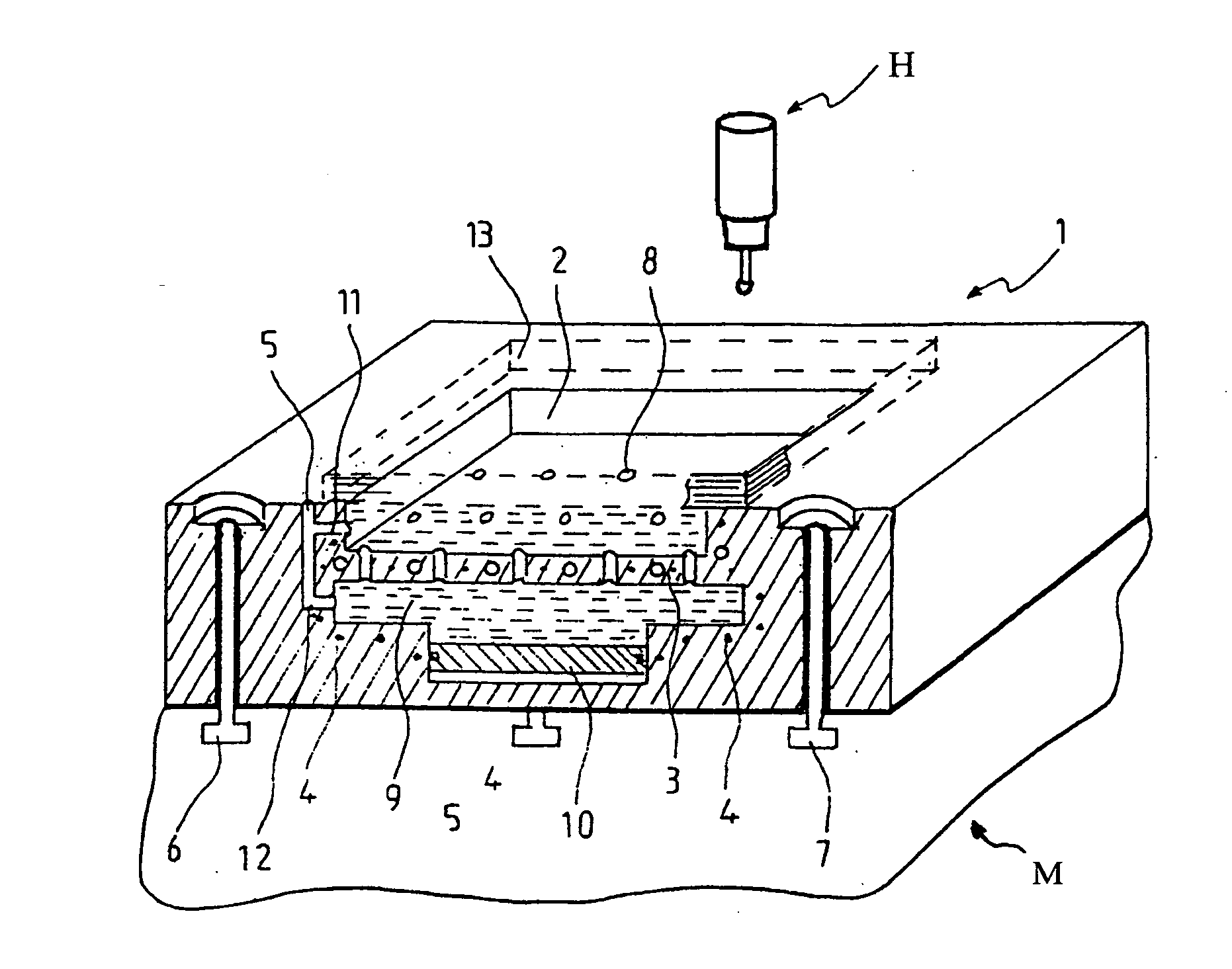

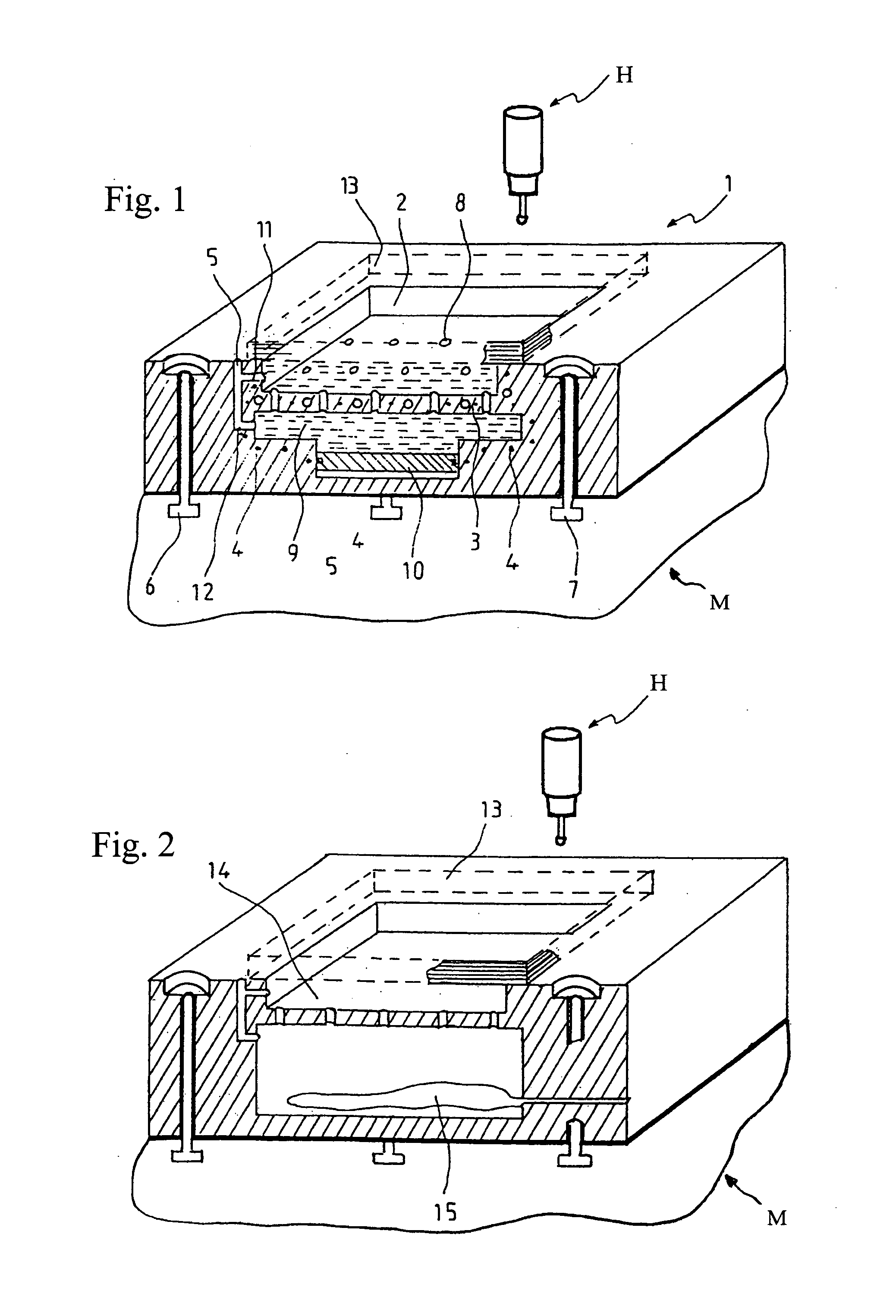

[0016]Referring to FIG. 1, the device (1) of the present invention comprises a tank (2), a baseplate (3), a heating circuit (4) and a fluid-circulation circuit (5). The device (1) is fitted, for example, by nuts (6, 7) onto a flat surface, for example, the bed of a machine tool (M), beneath a head (H) for machining a plate or part which is to be received and retained in position on the machine tool (M) by the device (1) as will be described more fully below. The head (H), the machine tool (M) and their manner of operation in a rapid prototyping process are known, for example, from the above-referenced European Patent No. 0 585 502-B1, and French Patent Applications No. 98 14687 and No. 98 14688.

[0017]The bottom of the tank (2) includes a perforated plate (3). Resistive heating elements (4) and fluid-circulating tubes (5) pass longitudinally through the perforated plate (3). Perforations (8) are formed transversely in the plate (3) and place the free face of the tank (2) in communica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shape | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com