Flexible clamp

a clamping and flexible technology, applied in the direction of snapping fasteners, heat collector mounting/support, light and heating apparatus, etc., can solve the problems of increasing the total cost of solar panel installation, increasing labor costs and related overhead, and preventing the clamp from effectively stabilizing an adjoining panel. , to achieve the effect of little separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

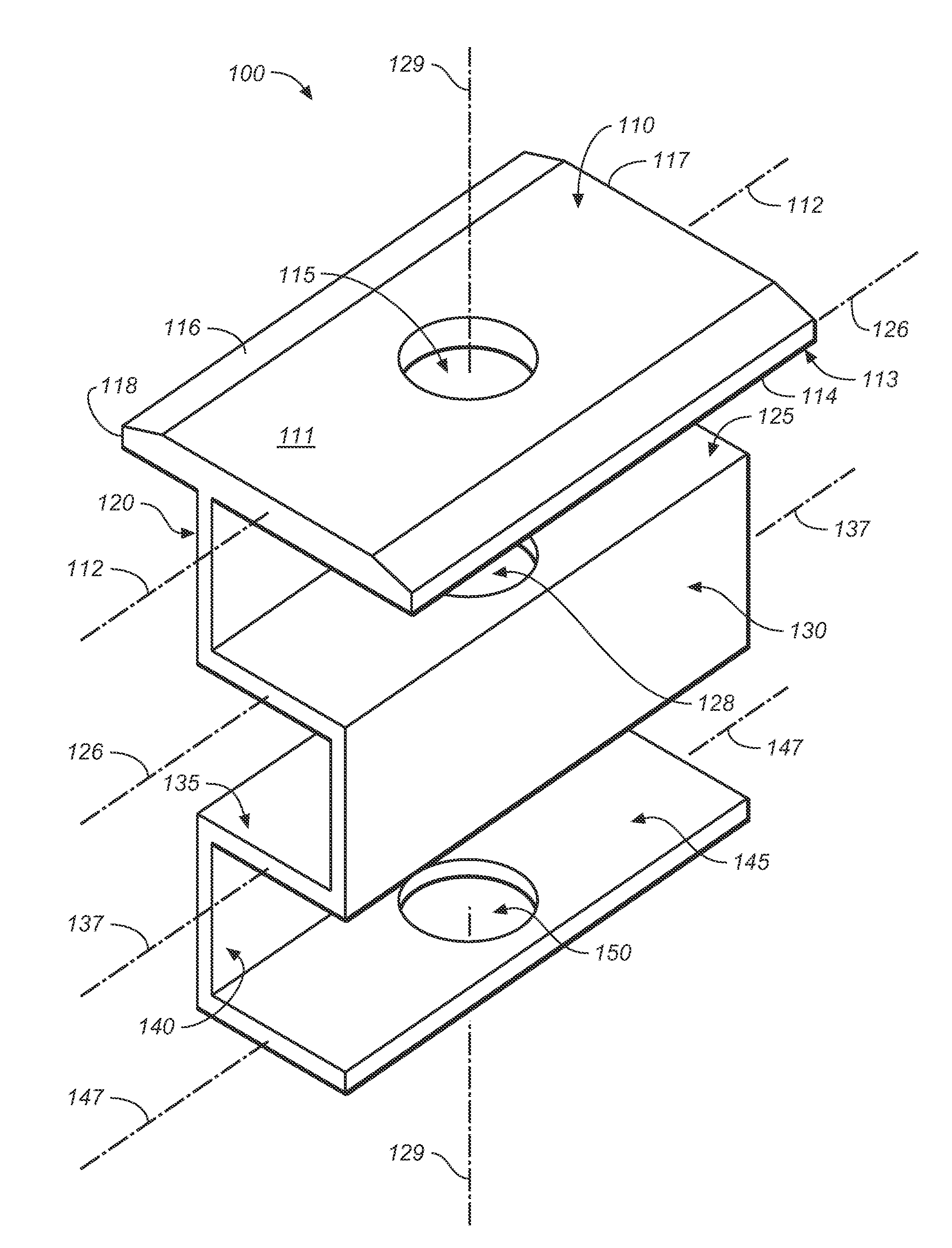

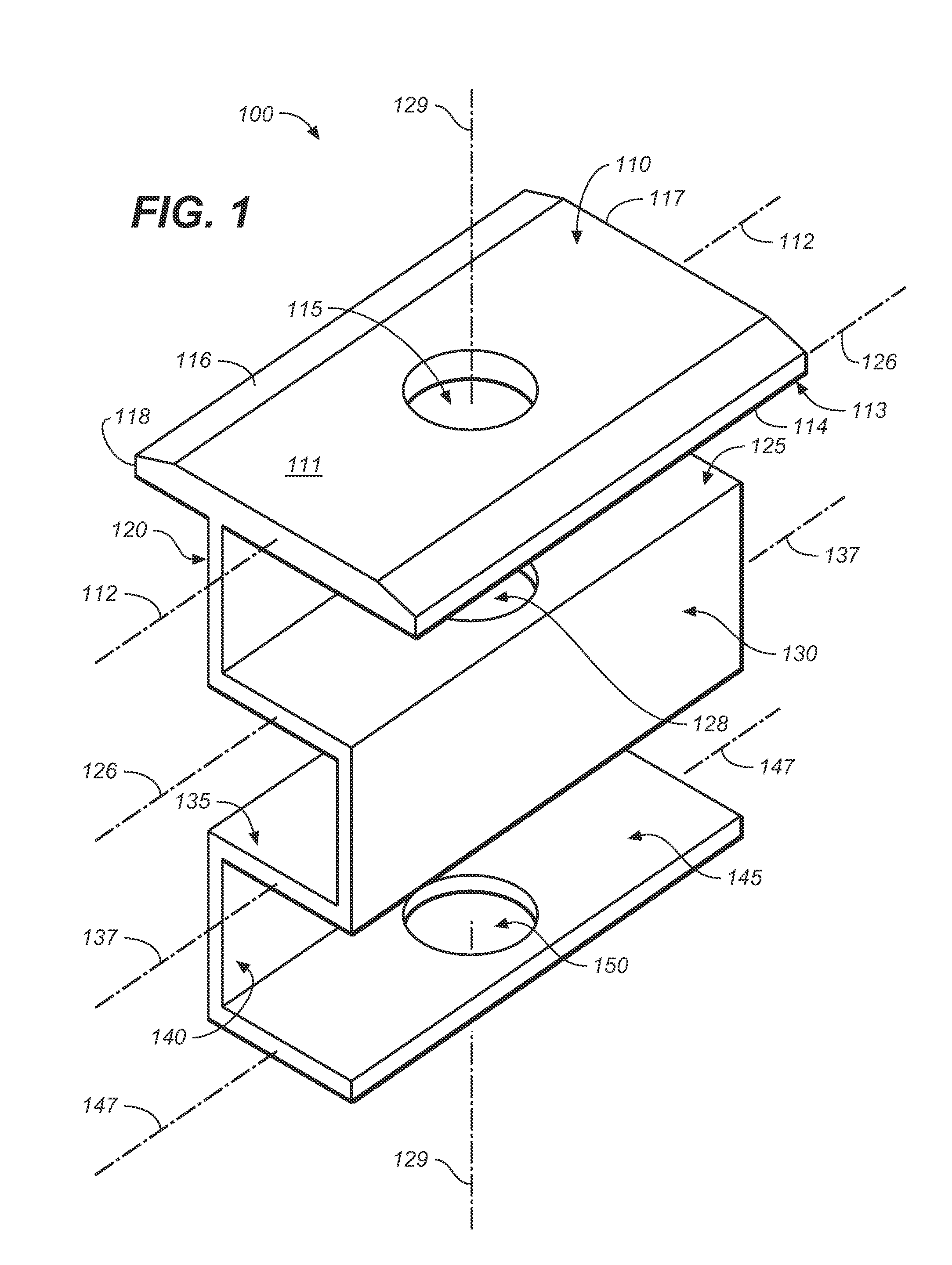

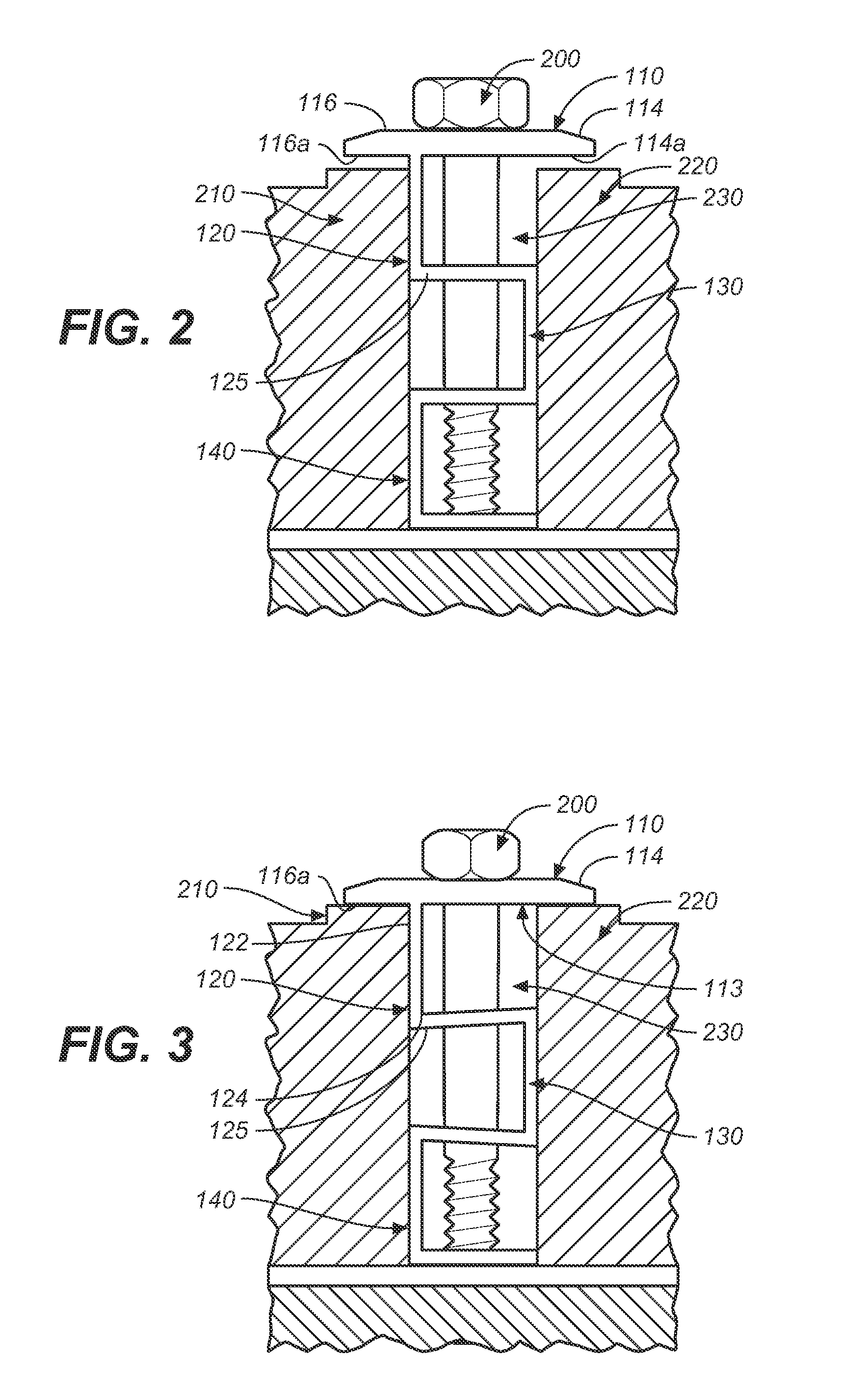

[0050]Referring to FIGS. 1 through 3, wherein like reference numerals refer to like components in the various views, there is illustrated therein a new and improved flexible clamp, generally denominated 100 herein.

[0051]FIG. 1 illustrates a first preferred embodiment of the inventive flexible clamp 100. The flexible clamp 100 has a flat captive flange 110 forming the top portion of the device. The captive flange 110 is generally rectangular in shape, having a longitudinal axis 111, a top face 112, a bottom face 113, a left side 114, a right side 116, a rear side 117, and a front side 118. A circular first bolt aperture 115 is located centrally in the captive flange 110 generally on the longitudinal axis 111. Extending perpendicularly, and medially to the captive flange longitudinal axis is a first vertical member 120, having a top edge 122 and a bottom edge 124. The top edge of the first vertical face 120 is attached to the bottom face 113 of the captive flange 110, slightly right o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com