Changing and Measuring Consistency

a technology of consistency and measurement method, applied in the field of changing and measuring consistency, can solve the problems of increasing the cost and environmental load, and clogging up the measuring device or analyzer, and achieving the effect of simple and small arrangement structure, accurate and rapid control, and advantageous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

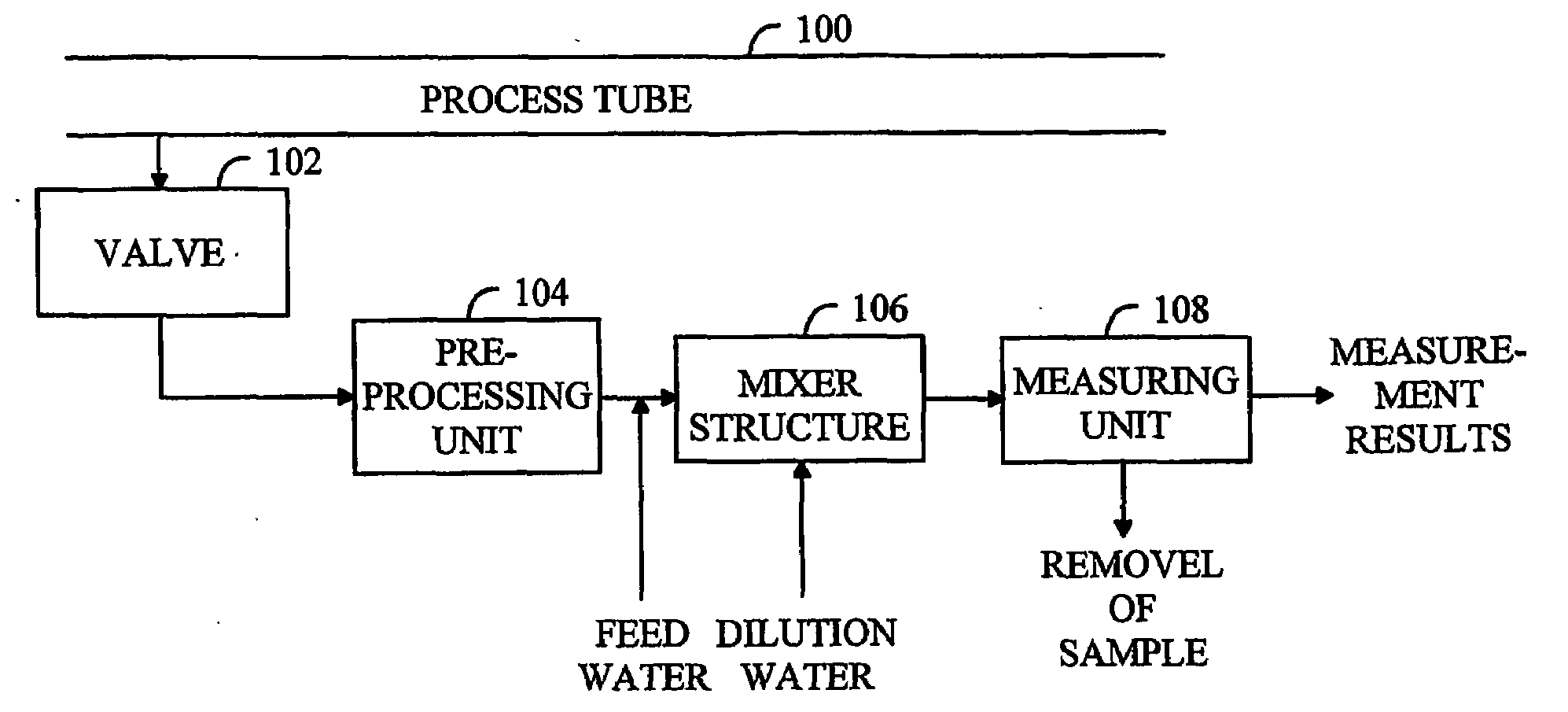

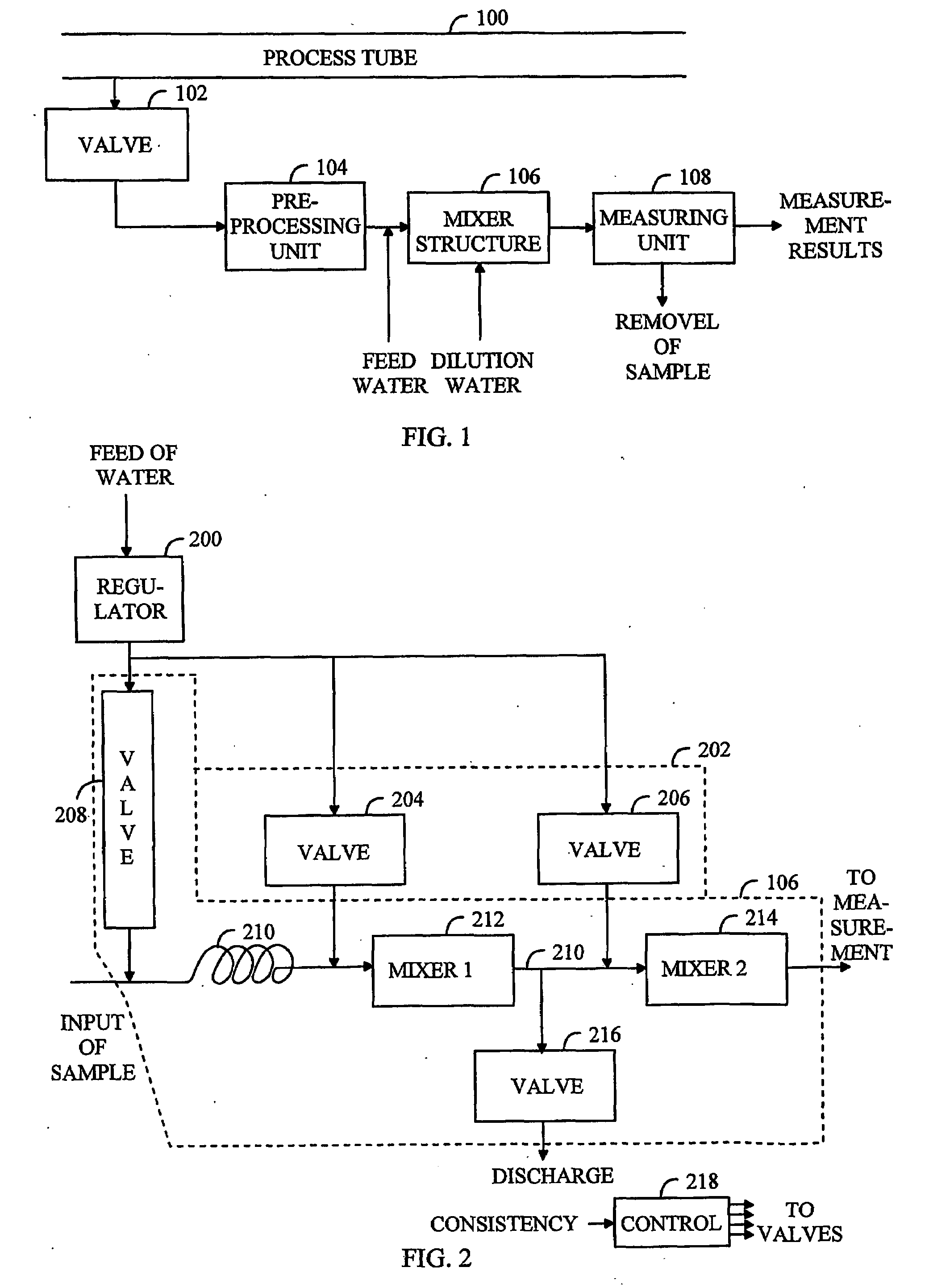

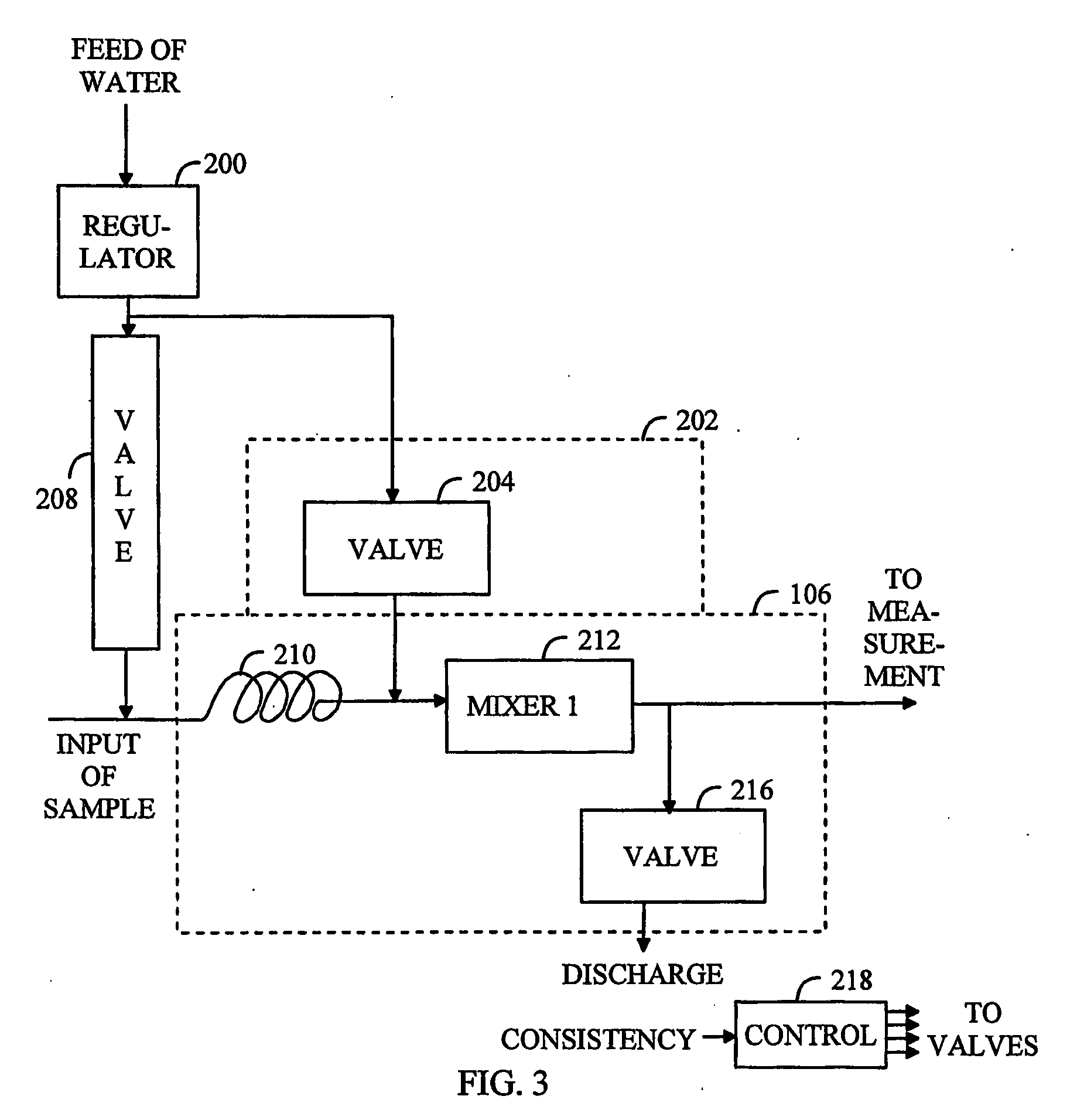

[0021]Let us first take a closer look at a measuring device shown in FIG. 1. A sample consisting of fibre suspension may be taken from a process tube 100 or from another process part. The sample is conveyed through a valve 102 possibly to a pre-processing unit 104 of the sample, where the consistency of the sample and other properties can be measured and changed. The fibre suspension comprises a liquid medium including particles of a solid, such as fibres. The fibre may be any fibre, such as animal fibre, plant fibre, cellulose fibre or synthetic fibre. The medium is typically water but in a common case the medium may be some other liquid. In the wood-processing industry the fibre 100 is typically wood fibre. The consistency of the sample taken from the process tube may vary from a couple of per cents to several per cents or it may even be over ten per cent. The pre-processing unit 104 may reduce the consistency accurately to a desired level for instance below one per cent. After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

| constant pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com