High power fiber laser of active lock phase multi-core interference coat pump and its making method

A technology of fiber lasers and multi-core fibers, which is applied in the direction of cladding fibers, lasers, laser components, etc., can solve the problems of strict consistency requirements, difficult process realization, unfavorable applications, etc., and achieve simplified manufacturing process requirements and simplified complex feedback Control system, easy to implement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

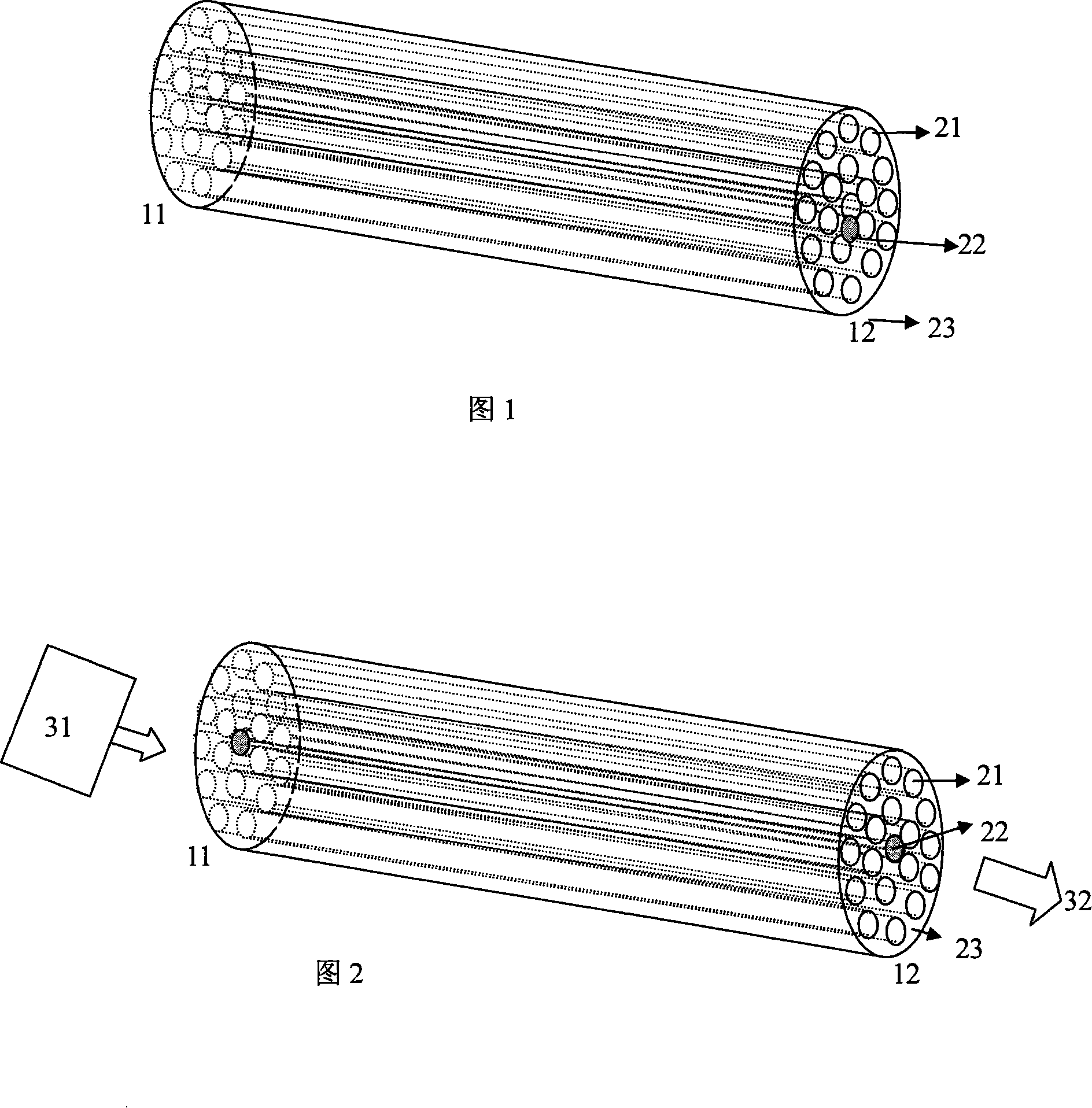

[0034] Using multi-core fiber to make multi-core active phase-locked fiber laser. Option 1, as shown in Figure 1, coat the 11 end faces of the multi-core optical fiber with a high-reflection film. Which wavelength the high-reflection film has high reflection depends on the needs. High-reflection films with different reflection wavelengths can be coated; The 12-end end face of the core fiber is cut flat, and the core in the center of the multi-core fiber is written into the grating. The wavelength of the grating is selected according to the wavelength to be excited, and no grating is written on the remaining cores of the 12-end end face. The centermost fiber core constitutes the main resonant cavity.

[0035] Option 2, as shown in Figure 1, write high-reflectivity gratings in all the cores of the 11-end facet of the multi-core optical fiber. Which wavelength the high-reflection grating is highly reflective depends on the need and can be written in different High-reflectivity g...

Embodiment 2

[0038] The present invention does not involve pumping methods, and can use end pumping, side pumping, coupler pumping, etc., all of which are owned by the patent holder or the document reporter.

[0039] The doped fiber used in Embodiment 2 is an ytterbium-doped fiber, and a resonant cavity is constructed in a multi-core fiber.

[0040] As shown in Figure 2, it is an actively phase-locked multi-core coherent fiber laser using end-pump coupling. The specific implementation plan is as follows:

[0041] Step 1. Prepare a multi-core cladding pumping fiber. The length of the multi-core fiber depends on the doping concentration, pump power and fiber background loss.

[0042] Step 2, as shown in FIG. 2 , smooth the end faces 11 and 12 of the multi-core cladding pumping fiber.

[0043] Step 3, coating the end face 11 with a film with high reflection to the resonant wavelength of the laser and a film with high transmittance to pump light such as 975nm.

[0044] Step 4: Write gratin...

Embodiment 3

[0049]The present invention does not involve pumping methods, and can use end pumping, side pumping, coupler pumping, etc., all of which are owned by the patent holder or the document reporter.

[0050] The doped fiber used in Embodiment 3 is an ytterbium-doped fiber, and a resonant cavity is constructed in a multi-core fiber.

[0051] As shown in Figure 2, it is an actively phase-locked multi-core coherent fiber laser using end-pump coupling. The specific implementation plan is as follows:

[0052] Step 1. Prepare a multi-core cladding pumping fiber. The length of the multi-core fiber depends on the doping concentration, pump power and fiber background loss.

[0053] Step 2, as shown in FIG. 2 , smooth the end faces 11 and 12 of the multi-core cladding pumping fiber.

[0054] Step 3, writing gratings in all the fiber cores in the end face 11, and the reflection wavelengths of the written gratings are the same.

[0055] Step 4: Write gratings in the middle core 22 of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com