Supporting Wall and Moulded Blocks of Concrete for Building a Supporting Wall

a technology of supporting wall and concrete, which is applied in the direction of bulkheads/piles, soil preservation, artificial islands, etc., can solve the problem of laborious laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

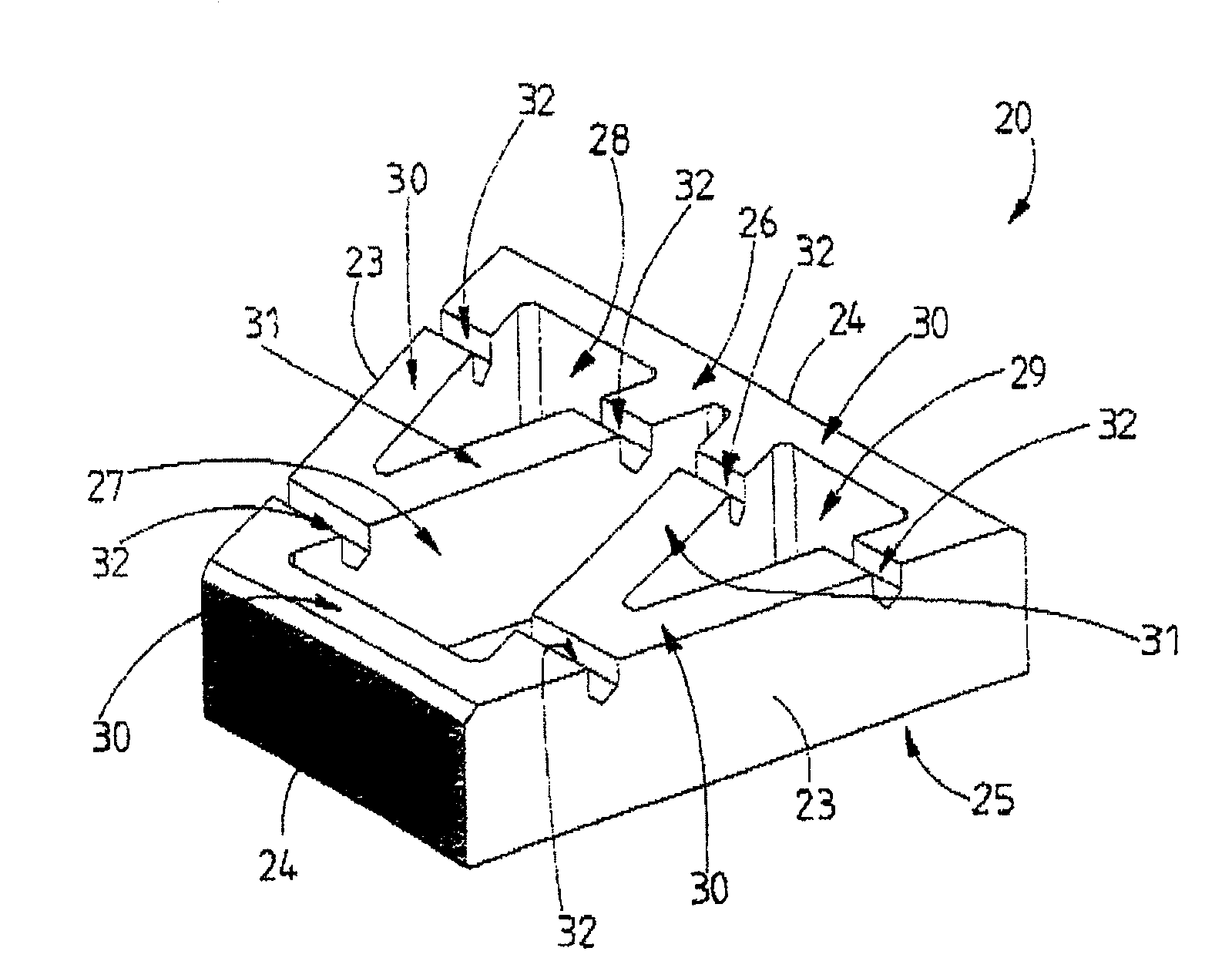

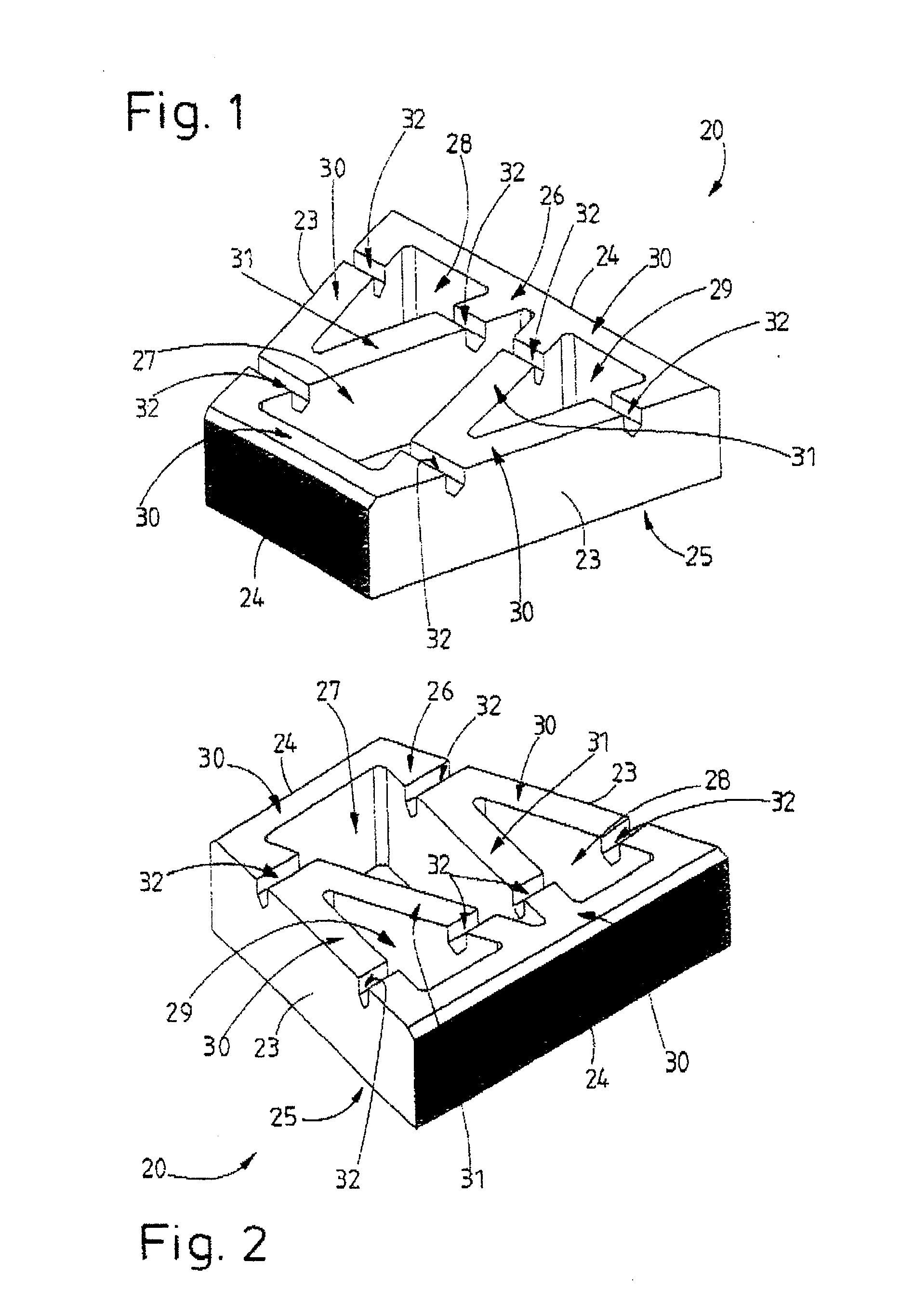

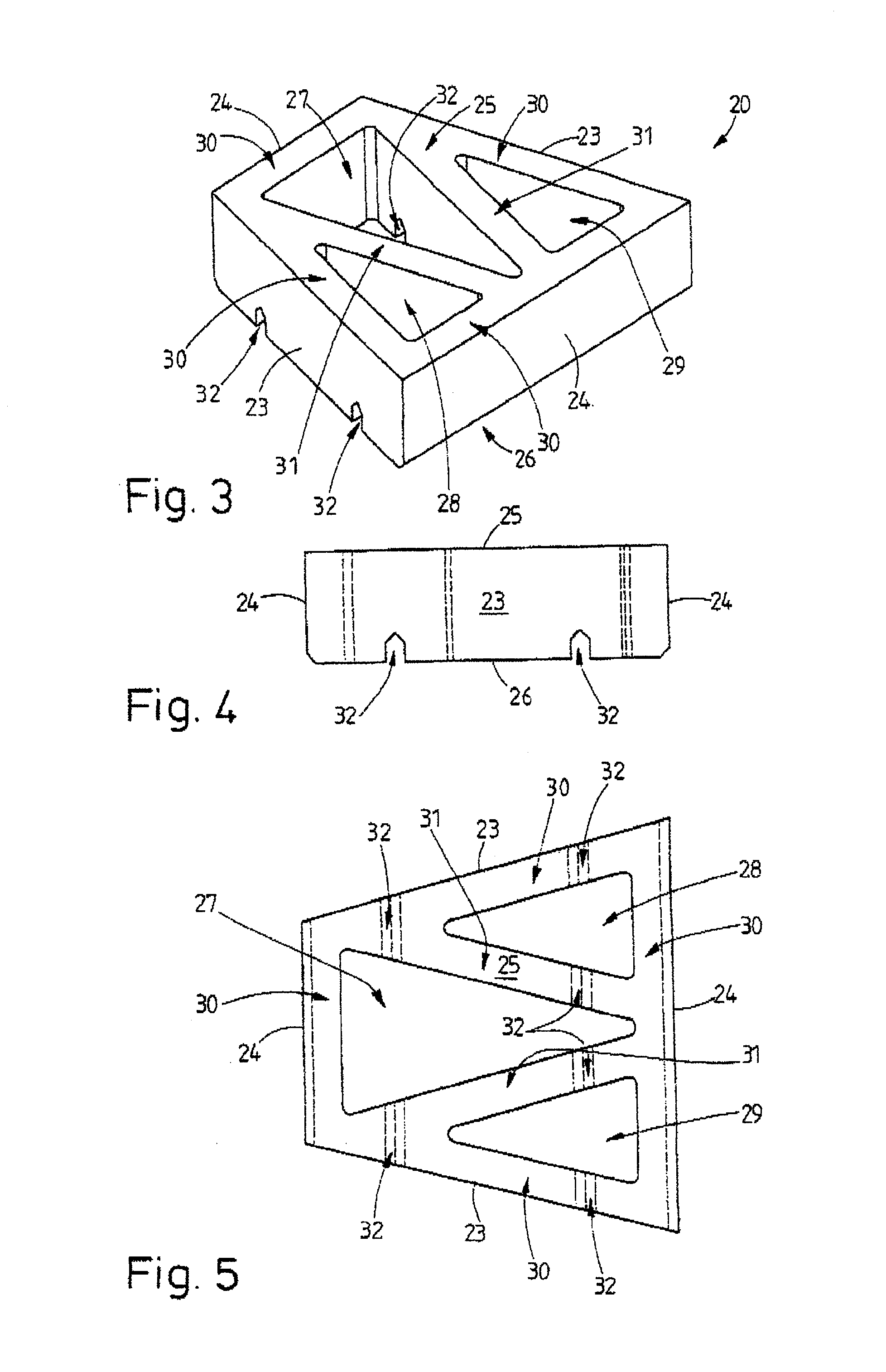

[0030]Shown in the figures are on the one hand a molded block 20 of concrete (FIGS. 1 to 5) and on the other hand supporting walls 21 comprising such molded blocks (FIGS. 6 to 10). FIGS. 11 to 13 show laying variants of the molded block 20. The molded block 20 shown in FIGS. 1 to 5 is suitable for building walls of any type. The molded blocks 20 can be laid without mortar, for example as a vertical wall or the like, or as a supporting wall 21 with an inclination against an earth backfill 22.

[0031]The molded blocks 20 have in each case a number of upright side walls 23, 24, and also an essentially horizontally directed upper side 25 and underside 26. The molded blocks 20 are essentially trapezoidally formed in horizontal projection. In this case, two opposite side walls 24 are parallel to one another and two opposite side walls 23 converge toward one another.

[0032]The molded block 20 may be produced in conventional (concrete block) molds, so that the side walls 23, 34 are formed by u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com