Sliding Nozzle Device and Pouring Device

a technology of sliding nozzle and pouring device, which is applied in the direction of casting apparatus, melt-holding vessel, manufacturing tools, etc., can solve the problems of lack of practical use and lack of reliability of the sliding mechanism of the sliding apparatus described in patent document 2 , to achieve the effect of convenient selective setting and execution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

(Operation of Embodiment)

[0056]Next, a description will be given of an operation of the sliding nozzle apparatus 12 structured as mentioned above.

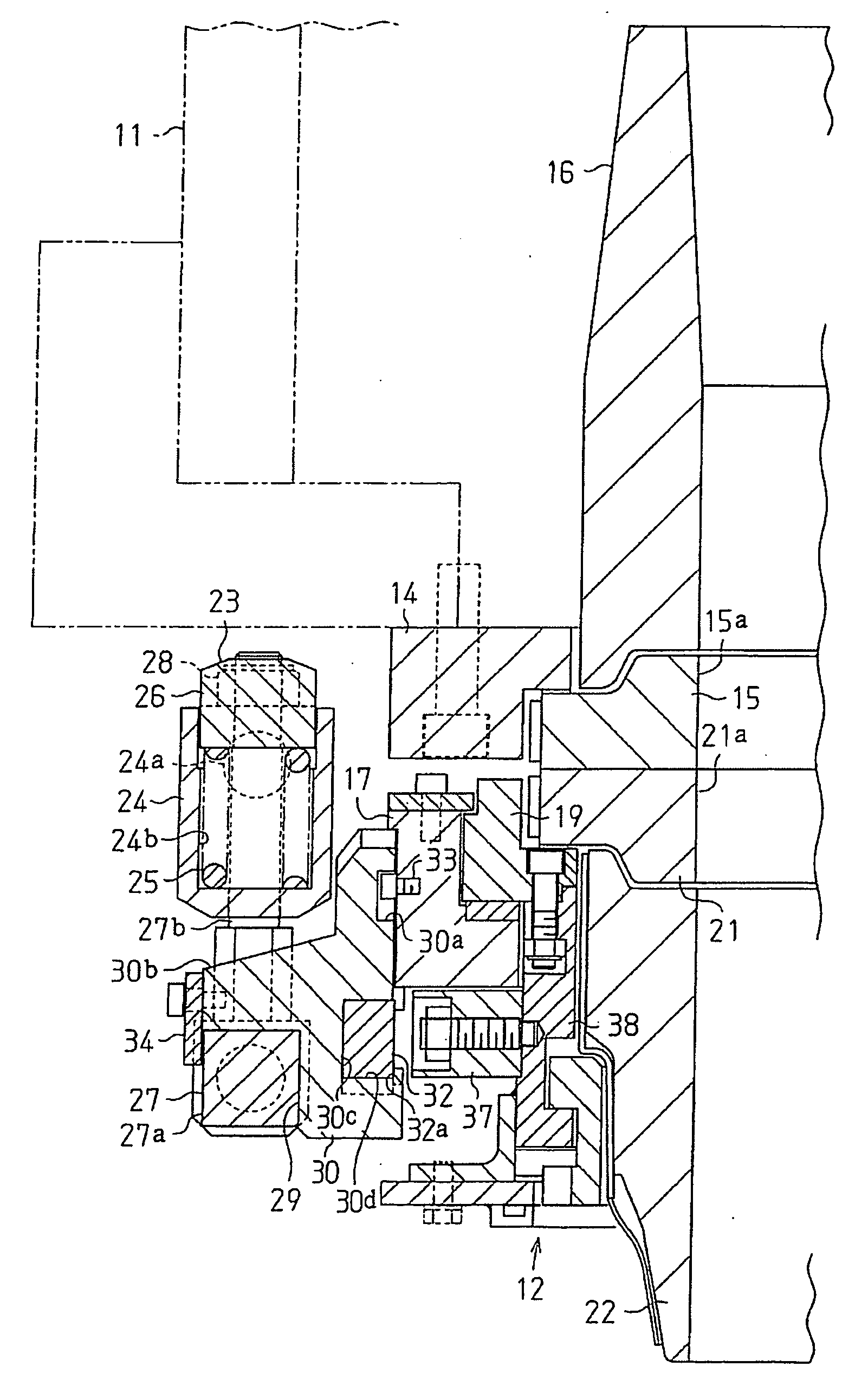

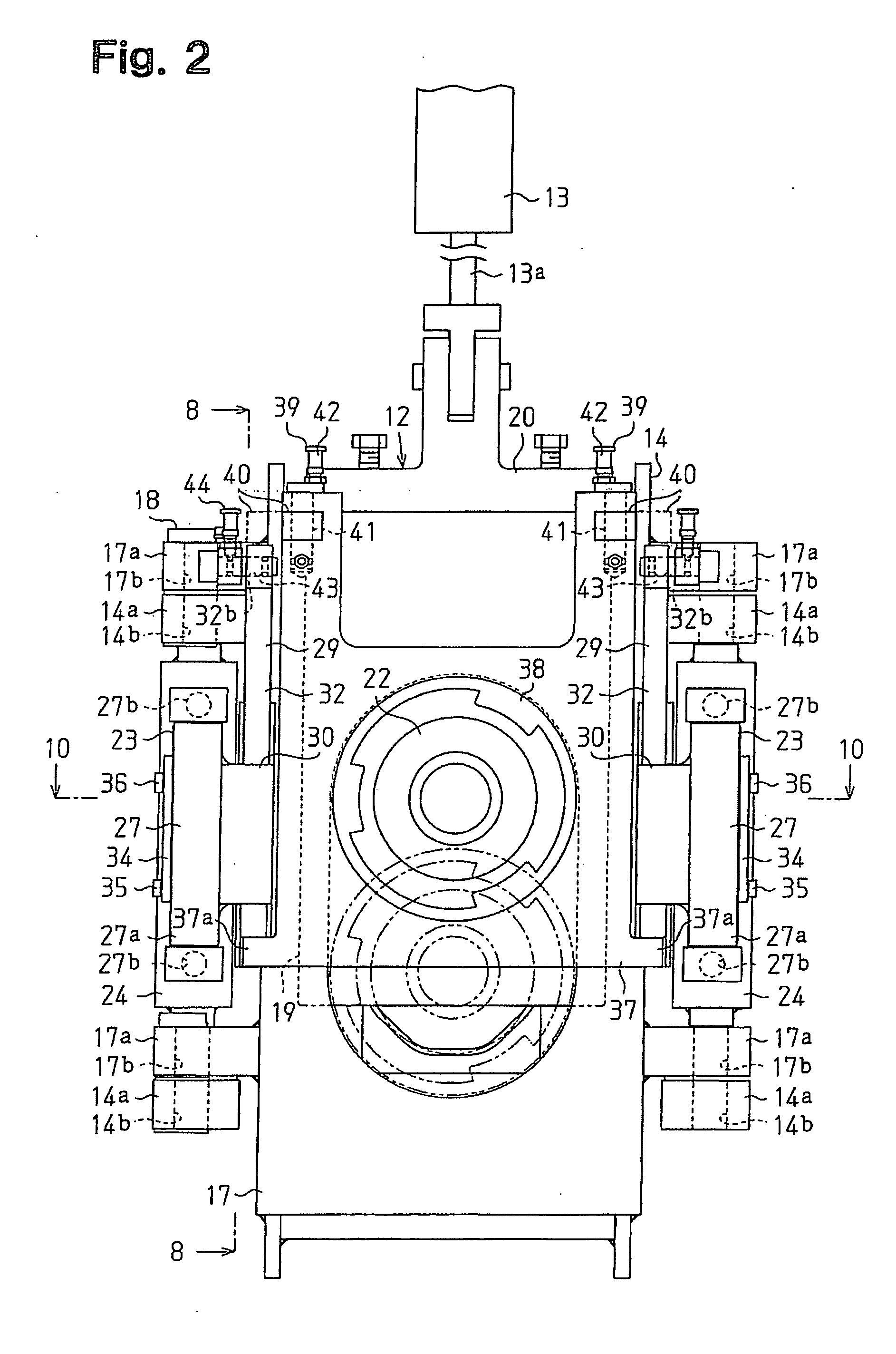

[0057]At a time of a normal use of the sliding nozzle apparatus 12, the opening and closing metal frame 17 is arranged at the closed position with respect to the fixed metal frame 14, and the holding members 27 of the pressurizing mechanisms 23 are rotated and arranged at the held position with respect to the opening and closing metal frame 17, as shown in FIGS. 6 and 7. In this state, as shown by a two-dot chain line in FIG. 4, the sliding metal frame 19 is moved to a lower side in FIG. 4, and the passage between the nozzle holes 15a and 21a of both the plates 15 and 21 is closed. Further, as shown by a solid line in FIG. 8, the cam members 32 are moved to one end (an upper end in FIG. 8) in a moving range, and the fixing pins 43 are engaged with the engagement holes 32b, thereby being fixed to the opening and closing metal frame 17.

[0058...

modified examples

[0069]In this case, the embodiment can be embodied by being changed as follows.

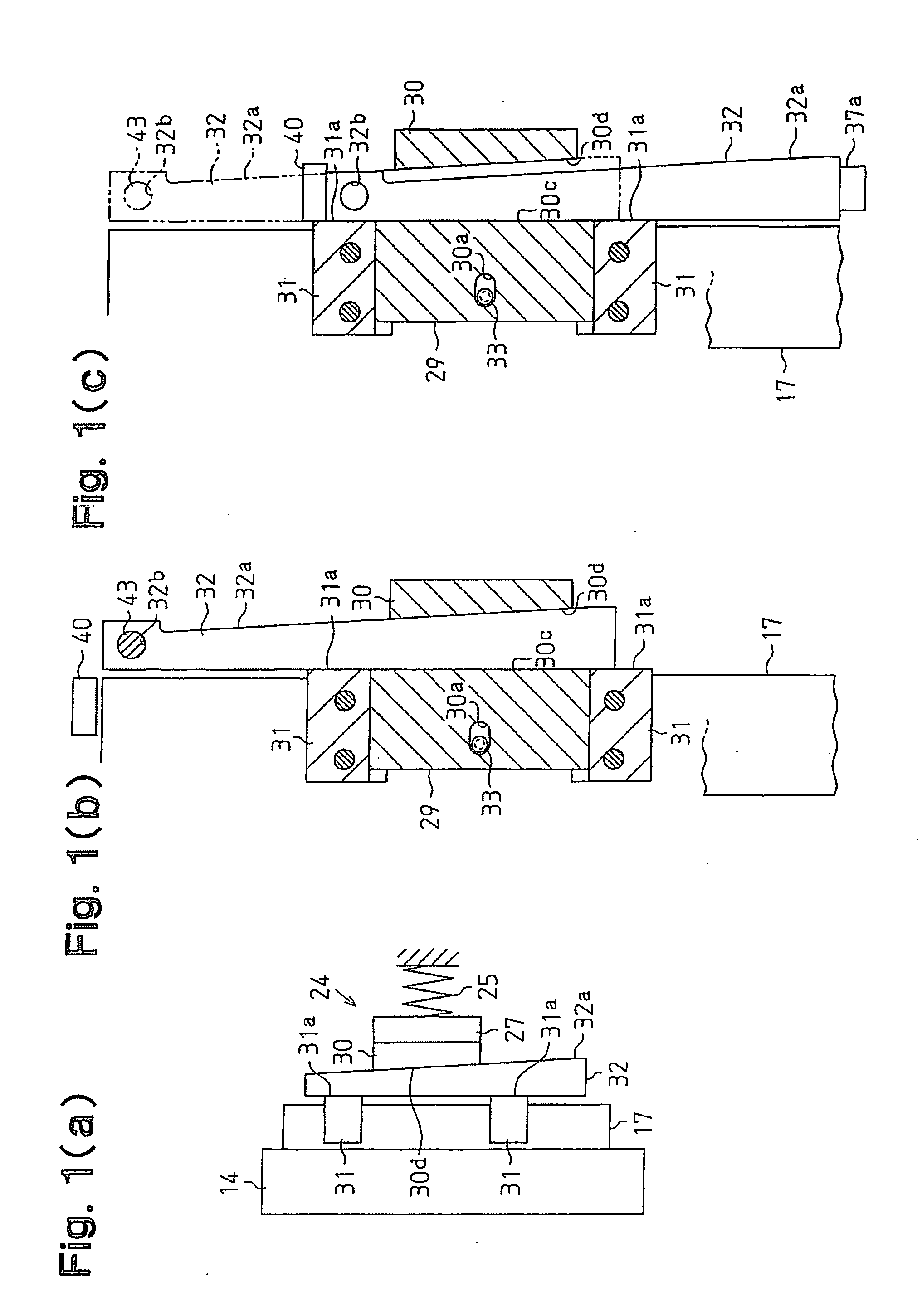

[0070]The structure may be made such that the moving members 30 are omitted, the cam members 32 are directly brought into contact with the holding members 27 of the pressurizing mechanisms 23, and the holding members 27 are moved against the spring force of the coil springs 25 on the basis of the cam operation.

[0071]The structure may be made such that the sliding metal frame 19 and the interlocking frame 37 are integrated, and the sliding metal frame 19 is provided with a means such as the engagement projection 37a or the like for supporting the cam member 32.

[0072]The structure may be made such that the cam surfaces 30d and 32a are provided in any one of the moving member 30 and the cam member 32.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressurizing force | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com