Split Mounting Type Square Column Assembly

a square column and mounting plate technology, applied in the direction of other domestic objects, walls, show shelves, etc., can solve the problems of personal injury and potential safety hazards, and achieve the effect of improving safety and reliability of exhibition equipment and facilitating the assembly of exhibition equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

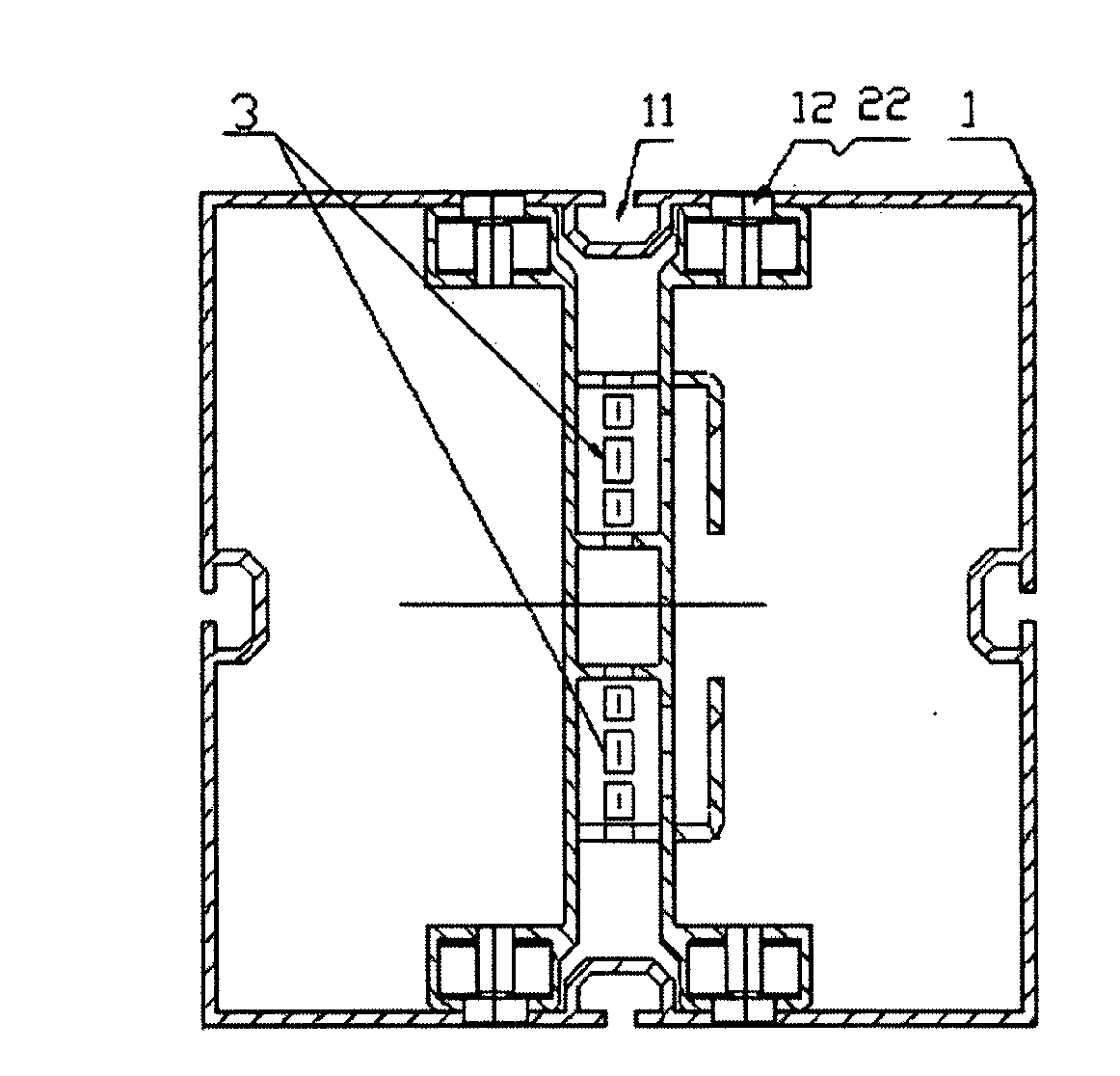

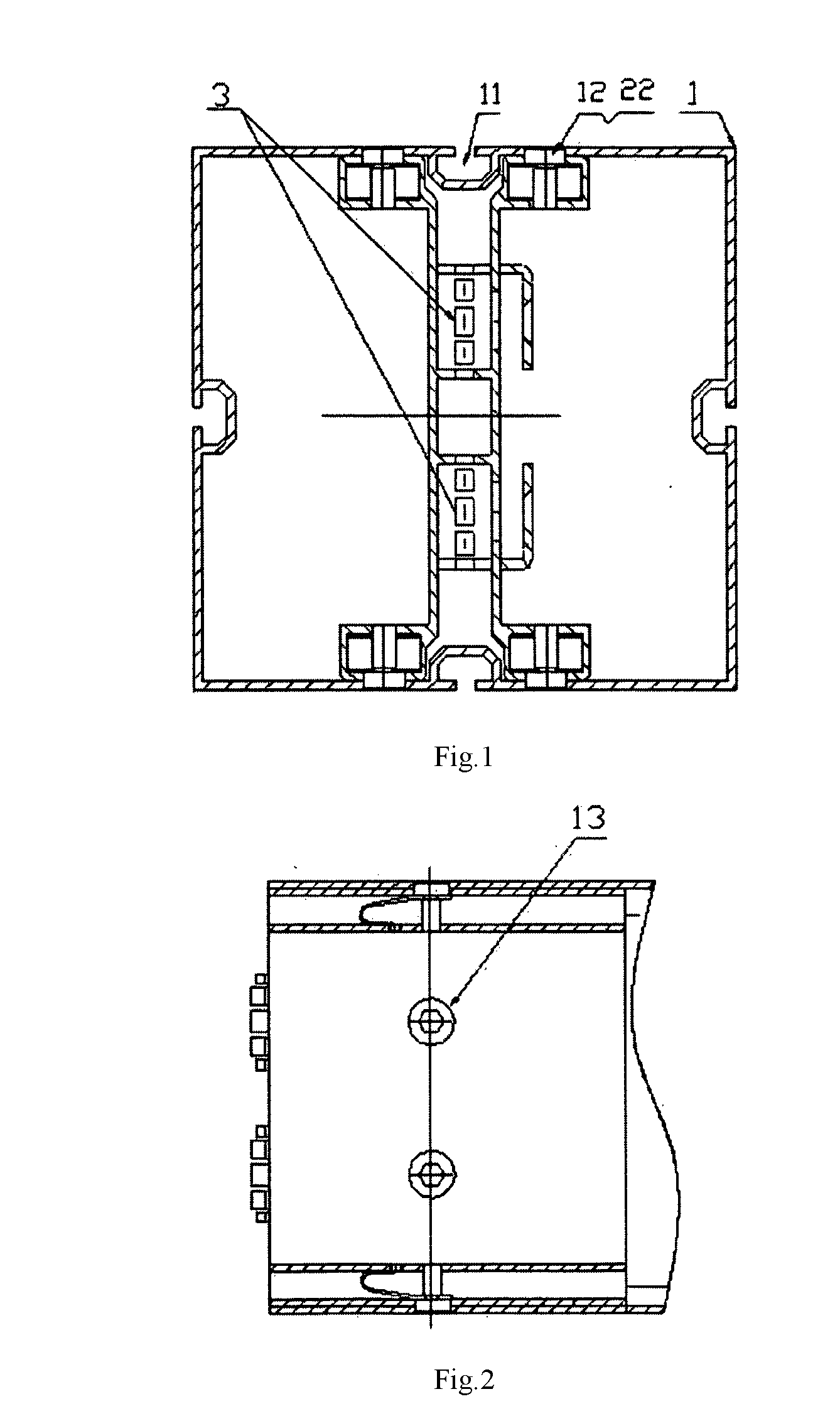

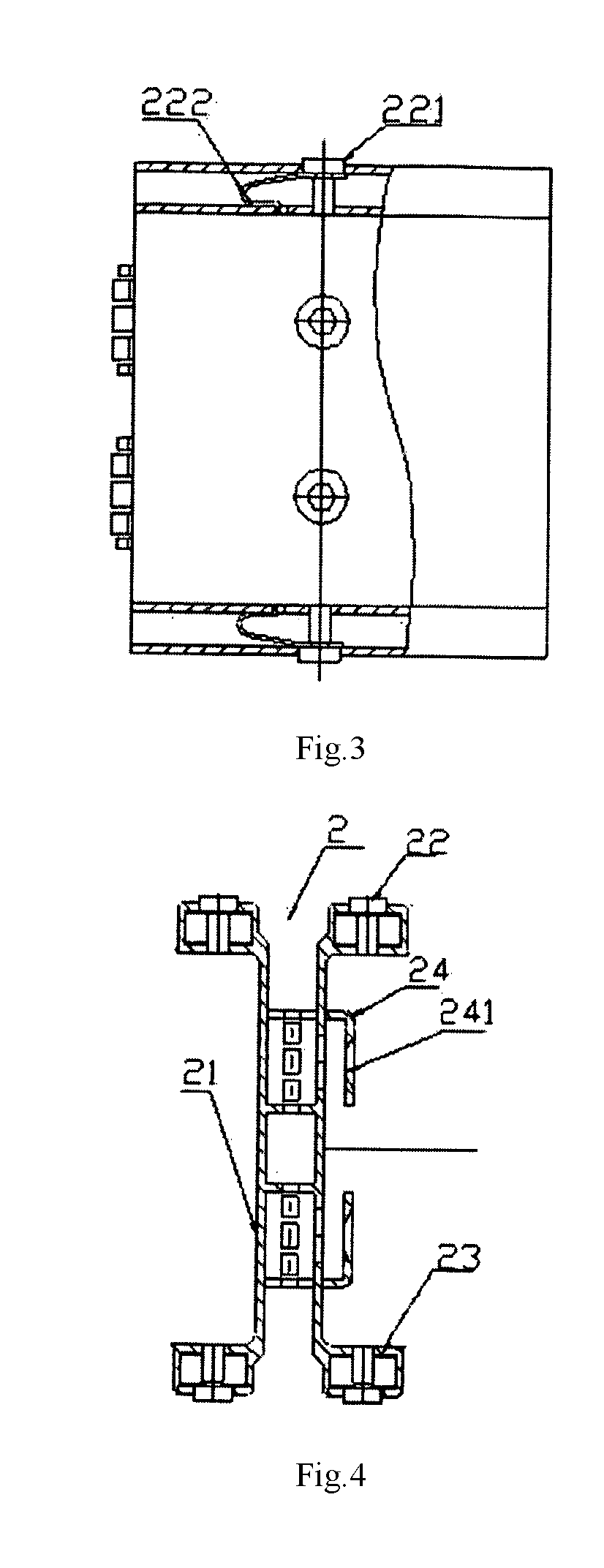

[0016]A split mounting type square column assembly for exhibition equipment, comprising a square column 1, a embedded type supporting frame 2, and a connecting lock 3; wherein, said connecting lock 3 is removable located in said embedded type supporting frame 2; said embedded type supporting frame 2 is removable located in said square column 1, at least one outside surface of said square column 1 has a connecting groove 11, and a quantity of positioning mounting holes 12 is arranged outside of the area of connecting groove 11 on outside surface of said square column 1; said embedded type supporting frame 2 comprises a supporting frame body 21, a spring pin 22, and a spring keyway 23; said spring pin 22 is located on said spring keyway 23; in the initial state, said spring pin 22 overhangs from said spring keyway 23, said spring keyway 23 is located on said supporting frame body 21, therefore the moving pathway of said spring cotter 22 could pass through the positions of said positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com